Prototype testing identifies design flaws and verifies functionality under controlled conditions, ensuring that technical specifications meet initial requirements. Final production testing confirms that each manufactured unit adheres to quality standards and performs reliably in real-world scenarios, preventing defective products from reaching customers. Both testing phases are critical for product development but serve distinct purposes in validating design integrity and manufacturing consistency.

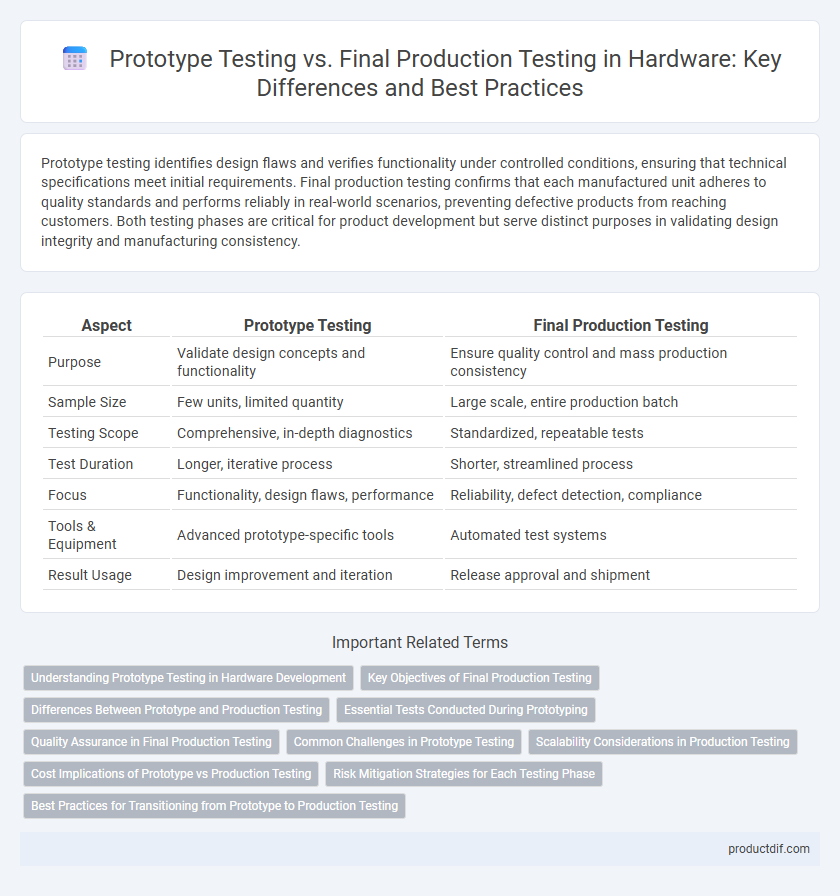

Table of Comparison

| Aspect | Prototype Testing | Final Production Testing |

|---|---|---|

| Purpose | Validate design concepts and functionality | Ensure quality control and mass production consistency |

| Sample Size | Few units, limited quantity | Large scale, entire production batch |

| Testing Scope | Comprehensive, in-depth diagnostics | Standardized, repeatable tests |

| Test Duration | Longer, iterative process | Shorter, streamlined process |

| Focus | Functionality, design flaws, performance | Reliability, defect detection, compliance |

| Tools & Equipment | Advanced prototype-specific tools | Automated test systems |

| Result Usage | Design improvement and iteration | Release approval and shipment |

Understanding Prototype Testing in Hardware Development

Prototype testing in hardware development involves evaluating early versions of a device to identify design flaws, functionality issues, and performance limitations before mass production. This phase focuses on iterative refinement through rigorous functional, stress, and environmental tests to ensure the design meets technical specifications and user requirements. Effective prototype testing reduces downstream production costs and improves product reliability by uncovering potential failures early in the development cycle.

Key Objectives of Final Production Testing

Final production testing ensures every hardware unit meets strict quality and functionality standards before market release, emphasizing defect detection and operational reliability. It verifies consistent performance across large-scale manufacturing, reducing failure rates and warranty costs. This stage validates compliance with design specifications and regulatory requirements, securing product safety and customer satisfaction.

Differences Between Prototype and Production Testing

Prototype testing primarily focuses on validating design functionality, identifying hardware flaws, and ensuring basic performance under controlled conditions. Final production testing emphasizes quality assurance, reliability, and compliance with manufacturing standards through rigorous, repeatable processes to detect defects in mass-produced units. The key differences lie in testing scope, with prototypes undergoing exploratory assessments, while production tests target consistent yield and defect elimination.

Essential Tests Conducted During Prototyping

Prototype testing involves essential evaluations such as functionality verification, thermal performance analysis, and signal integrity checks to identify design flaws early in the hardware development process. Electrical stress tests and component compatibility assessments ensure prototype reliability under expected operating conditions. These tests provide critical data to refine the design before moving to final production testing, which emphasizes consistency and mass production readiness.

Quality Assurance in Final Production Testing

Final production testing ensures hardware quality by rigorously validating each unit against strict performance criteria to detect defects missed during prototype testing. This phase employs automated test systems and statistical process control to maintain consistent manufacturing standards and minimize field failures. Quality assurance in final production testing guarantees product reliability, compliance with specifications, and customer satisfaction.

Common Challenges in Prototype Testing

Prototype testing often faces challenges such as incomplete design validation due to limited test coverage and the presence of unforeseen hardware defects that are not apparent in initial assessments. Inconsistent test environments and the lack of standardized testing protocols can lead to unreliable results and difficulty in replicating issues. Additionally, tight development schedules and resource constraints frequently hinder comprehensive prototype evaluation, delaying feedback loops essential for design optimization.

Scalability Considerations in Production Testing

Scalability considerations in production testing demand that prototype testing methods evolve to handle increased volumes and complexity efficiently. Final production testing must integrate automated systems and parallel processing to maintain throughput without compromising accuracy or quality. Ensuring scalable testing frameworks minimizes bottlenecks and supports consistent performance as manufacturing shifts from prototype to mass production.

Cost Implications of Prototype vs Production Testing

Prototype testing incurs higher per-unit costs due to limited quantities, extensive manual inspection, and iterative design modifications. Final production testing benefits from economies of scale, automated processes, and streamlined quality control, significantly reducing cost per unit. Businesses must balance upfront prototype expenses against optimized production testing to ensure overall cost-efficiency in hardware development.

Risk Mitigation Strategies for Each Testing Phase

Prototype testing emphasizes identifying design flaws and functional issues early, using rigorous stress and environmental tests to uncover potential failures before scaling. Final production testing focuses on ensuring consistent product quality and reliability through automated inspections and end-of-line functional tests that detect manufacturing defects. Both phases implement risk mitigation strategies by combining statistical process control and failure mode analysis to minimize defects and reduce costly recalls.

Best Practices for Transitioning from Prototype to Production Testing

Prototype testing emphasizes identifying design flaws and validating functionality through iterative diagnostics, while final production testing focuses on ensuring consistent quality and reliability across high-volume manufacturing. Best practices for transitioning include standardizing test procedures, automating repetitive tasks, and refining test coverage based on prototype findings to optimize efficiency and reduce false positives. Incorporating real-time data analytics and feedback loops during final production testing enhances defect detection and drives continuous improvement.

Prototype Testing vs Final Production Testing Infographic

productdif.com

productdif.com