Environmental testing evaluates hardware pet devices under various physical conditions such as temperature, humidity, and vibration to ensure durability and performance in real-world environments. Regulatory testing verifies compliance with industry standards and legal requirements, ensuring the device meets safety, electromagnetic compatibility, and communication protocols. Both testing methods are critical for certifying product reliability and market readiness.

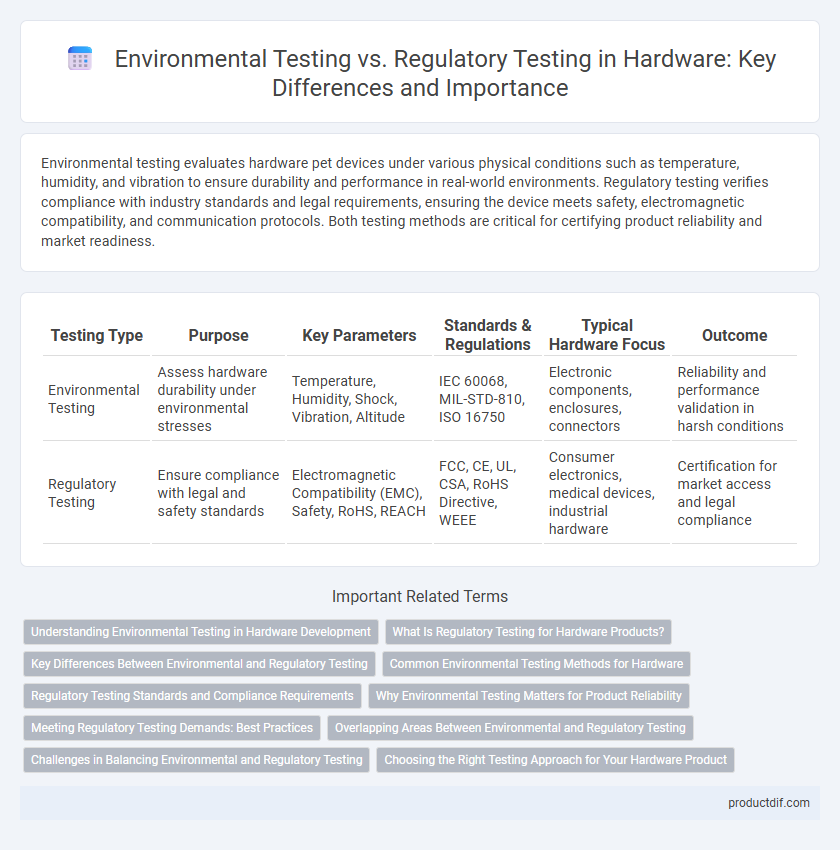

Table of Comparison

| Testing Type | Purpose | Key Parameters | Standards & Regulations | Typical Hardware Focus | Outcome |

|---|---|---|---|---|---|

| Environmental Testing | Assess hardware durability under environmental stresses | Temperature, Humidity, Shock, Vibration, Altitude | IEC 60068, MIL-STD-810, ISO 16750 | Electronic components, enclosures, connectors | Reliability and performance validation in harsh conditions |

| Regulatory Testing | Ensure compliance with legal and safety standards | Electromagnetic Compatibility (EMC), Safety, RoHS, REACH | FCC, CE, UL, CSA, RoHS Directive, WEEE | Consumer electronics, medical devices, industrial hardware | Certification for market access and legal compliance |

Understanding Environmental Testing in Hardware Development

Environmental testing in hardware development evaluates a device's performance under various physical conditions such as temperature, humidity, vibration, and shock to ensure reliability and durability in real-world environments. This testing helps identify potential failures caused by environmental stressors before product release, contributing to higher quality and customer satisfaction. Unlike regulatory testing, which focuses on compliance with legal standards, environmental testing provides critical insights into the hardware's operational limits and robustness.

What Is Regulatory Testing for Hardware Products?

Regulatory testing for hardware products involves evaluating devices to ensure compliance with specific government standards and legal requirements, including safety, electromagnetic compatibility (EMC), and environmental regulations. This testing verifies that products meet certifications such as CE, FCC, UL, or RoHS before entering the market. Passing regulatory tests helps manufacturers avoid legal penalties and ensures reliable, safe hardware performance for end users.

Key Differences Between Environmental and Regulatory Testing

Environmental testing evaluates hardware performance under simulated conditions such as temperature, humidity, vibration, and shock to ensure durability and reliability in real-world environments. Regulatory testing verifies compliance with industry standards and legal requirements, focusing on safety, electromagnetic compatibility (EMC), and hazardous substance levels to meet certification criteria. The key difference lies in environmental testing assessing operational robustness, while regulatory testing ensures adherence to mandatory regulations and market entry prerequisites.

Common Environmental Testing Methods for Hardware

Common environmental testing methods for hardware include thermal cycling, humidity exposure, vibration testing, and salt spray corrosion tests, which assess device durability under various stress conditions. These tests simulate real-world environments to ensure hardware reliability and performance over time. Regulatory testing typically incorporates these methods but emphasizes compliance with specific industry standards and safety certifications.

Regulatory Testing Standards and Compliance Requirements

Regulatory testing standards such as UL, CE, FCC, and RoHS ensure hardware products meet mandatory safety, electromagnetic compatibility, and environmental compliance requirements before market entry. Compliance with these standards involves rigorous assessments including electrical safety, emissions, and hazardous substances restrictions to avoid legal penalties and ensure consumer protection. Understanding and aligning with region-specific regulatory frameworks streamlines certification processes and facilitates global market access for hardware manufacturers.

Why Environmental Testing Matters for Product Reliability

Environmental testing evaluates hardware performance under real-world conditions such as temperature fluctuations, humidity, vibration, and shock to ensure product durability and operational stability. This testing identifies potential failure modes and design weaknesses that regulatory testing, which focuses primarily on compliance and safety standards, may not expose. By simulating extreme environmental stresses, manufacturers can enhance product reliability, reduce warranty costs, and improve customer satisfaction.

Meeting Regulatory Testing Demands: Best Practices

Meeting regulatory testing demands requires precise environmental testing protocols that simulate real-world conditions such as temperature, humidity, vibration, and shock to ensure hardware durability and compliance. Implementing standardized test methods from agencies like UL, IEC, and MIL-STD guarantees alignment with global regulatory frameworks and reduces the risk of product recalls. Integrating automated data collection and analysis during environmental testing enhances accuracy, accelerates compliance reporting, and strengthens certification confidence.

Overlapping Areas Between Environmental and Regulatory Testing

Environmental testing and regulatory testing often intersect in hardware validation, particularly in areas such as temperature endurance, humidity resistance, and vibration tolerance. Both testing types evaluate the hardware's ability to maintain performance and safety standards under specified conditions to comply with industry regulations like IEC, MIL-STD, or RoHS. This overlap ensures devices meet environmental durability criteria while adhering to mandatory certification requirements for market approval.

Challenges in Balancing Environmental and Regulatory Testing

Balancing environmental testing and regulatory testing in hardware development presents challenges such as ensuring compliance with diverse international standards while maintaining product durability under extreme conditions. Environmental testing requires rigorous assessment of factors like temperature, humidity, and vibration to guarantee performance reliability, whereas regulatory testing demands strict adherence to safety, electromagnetic compatibility (EMC), and material usage requirements. Harmonizing these testing protocols necessitates integrated test planning and resource allocation to mitigate delays and cost overruns.

Choosing the Right Testing Approach for Your Hardware Product

Environmental testing evaluates hardware durability under extreme conditions such as temperature, humidity, and vibration to ensure product reliability in real-world scenarios. Regulatory testing verifies compliance with industry standards and legal requirements like FCC, CE, or RoHS certifications to guarantee market access and safety adherence. Selecting the right testing approach depends on the product's target environment, market regulations, and specific performance criteria to optimize development costs and reduce time to market.

Environmental Testing vs Regulatory Testing Infographic

productdif.com

productdif.com