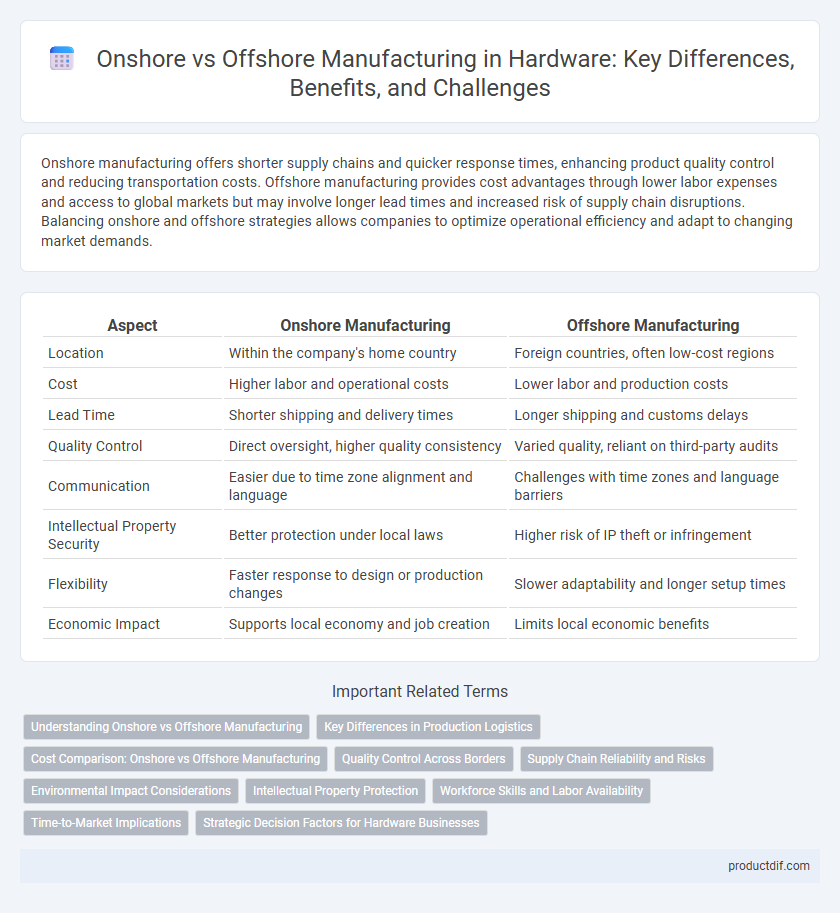

Onshore manufacturing offers shorter supply chains and quicker response times, enhancing product quality control and reducing transportation costs. Offshore manufacturing provides cost advantages through lower labor expenses and access to global markets but may involve longer lead times and increased risk of supply chain disruptions. Balancing onshore and offshore strategies allows companies to optimize operational efficiency and adapt to changing market demands.

Table of Comparison

| Aspect | Onshore Manufacturing | Offshore Manufacturing |

|---|---|---|

| Location | Within the company's home country | Foreign countries, often low-cost regions |

| Cost | Higher labor and operational costs | Lower labor and production costs |

| Lead Time | Shorter shipping and delivery times | Longer shipping and customs delays |

| Quality Control | Direct oversight, higher quality consistency | Varied quality, reliant on third-party audits |

| Communication | Easier due to time zone alignment and language | Challenges with time zones and language barriers |

| Intellectual Property Security | Better protection under local laws | Higher risk of IP theft or infringement |

| Flexibility | Faster response to design or production changes | Slower adaptability and longer setup times |

| Economic Impact | Supports local economy and job creation | Limits local economic benefits |

Understanding Onshore vs Offshore Manufacturing

Onshore manufacturing involves producing goods within the same country as the target market, ensuring shorter lead times and easier quality control compared to offshore alternatives. Offshore manufacturing typically offers cost savings by leveraging lower labor and production costs in foreign countries but can introduce challenges such as longer shipping times and increased logistical complexity. Understanding the trade-offs between onshore and offshore manufacturing is essential for optimizing supply chain efficiency, managing risks, and meeting compliance standards in hardware production.

Key Differences in Production Logistics

Onshore manufacturing offers shorter supply chains and faster lead times due to proximity to markets, reducing transportation costs and risks. Offshore manufacturing often involves complex logistics with longer shipping routes, increasing inventory holding and potential delays. Differences in production logistics impact responsiveness, cost efficiency, and supply chain resilience, crucial for hardware companies optimizing global operations.

Cost Comparison: Onshore vs Offshore Manufacturing

Onshore manufacturing typically incurs higher labor and operational costs due to stricter regulations and higher wages compared to offshore manufacturing hubs. Offshore manufacturing offers cost advantages through lower labor expenses and reduced overhead, though hidden costs such as shipping, tariffs, and longer lead times can offset initial savings. Accurate cost comparison requires analyzing total landed costs, including transportation, quality control, and potential risks associated with geopolitical instability.

Quality Control Across Borders

Onshore manufacturing ensures tighter quality control through proximity to production sites and direct oversight, reducing risks of defects and improving product consistency. Offshore manufacturing often faces challenges in maintaining uniform quality standards due to geographic distance, cultural differences, and communication barriers. Implementing robust quality management systems and real-time monitoring technologies can bridge these gaps and enhance product reliability across borders.

Supply Chain Reliability and Risks

Onshore manufacturing enhances supply chain reliability by reducing lead times and minimizing transportation disruptions, which is critical for hardware production requiring just-in-time inventory management. Offshore manufacturing introduces risks such as geopolitical instability, longer shipping routes, and customs delays, potentially causing supply chain volatility that can impact hardware quality and delivery schedules. Companies leveraging onshore facilities often experience improved responsiveness and lower supply chain risk, crucial for maintaining consistent hardware manufacturing operations.

Environmental Impact Considerations

Onshore manufacturing significantly reduces carbon emissions by minimizing transportation distances and enabling stricter compliance with environmental regulations. Offshore manufacturing often results in increased ecological footprint due to long shipping routes and variable enforcement of pollution controls. Evaluating the environmental impact involves assessing energy consumption, waste management practices, and local ecosystem effects in both manufacturing settings.

Intellectual Property Protection

Onshore manufacturing offers enhanced intellectual property protection due to stricter local regulations and more robust enforcement mechanisms, reducing the risk of IP theft. Offshore manufacturing often faces challenges with weaker IP laws and enforcement, increasing vulnerability to unauthorized replication and patent infringement. Choosing onshore production supports tighter control over proprietary hardware designs and confidential technological data.

Workforce Skills and Labor Availability

Onshore manufacturing benefits from a highly skilled workforce with specialized expertise tailored to advanced hardware production, ensuring superior quality and innovation. Labor availability in onshore locations tends to be consistent due to established educational institutions and technical training programs aligned with industry demands. Offshore manufacturing often faces challenges related to varying skill levels and less specialized labor pools, which can impact precision and increase the need for extensive training or supervision.

Time-to-Market Implications

Onshore manufacturing significantly reduces time-to-market by enabling faster communication, quicker prototyping, and streamlined logistics compared to offshore alternatives. Proximity to the target market allows for rapid response to design changes and demand fluctuations, minimizing delays in product delivery. Conversely, offshore manufacturing often encounters longer lead times due to complex supply chains, customs clearance, and potential geopolitical risks impacting production schedules.

Strategic Decision Factors for Hardware Businesses

Onshore manufacturing for hardware offers enhanced quality control, faster turnaround times, and reduced shipping costs, which are critical for businesses prioritizing precision and time-to-market. Offshore manufacturing provides cost efficiency and access to larger-scale production capabilities but introduces complexities such as supply chain risks, communication barriers, and intellectual property concerns. Hardware companies must strategically evaluate factors like proximity to customers, labor costs, regulatory compliance, and agility to optimize manufacturing decisions.

Onshore Manufacturing vs Offshore Manufacturing Infographic

productdif.com

productdif.com