Piezo sensors generate voltage when subjected to mechanical stress, making them ideal for detecting vibrations and pressure changes with high sensitivity and fast response times. Hall effect sensors measure magnetic fields to determine position, speed, or current, providing reliable contactless detection in various industrial and automotive applications. Choosing between piezo and Hall effect sensors depends on the specific use case, such as mechanical force sensing versus magnetic field detection.

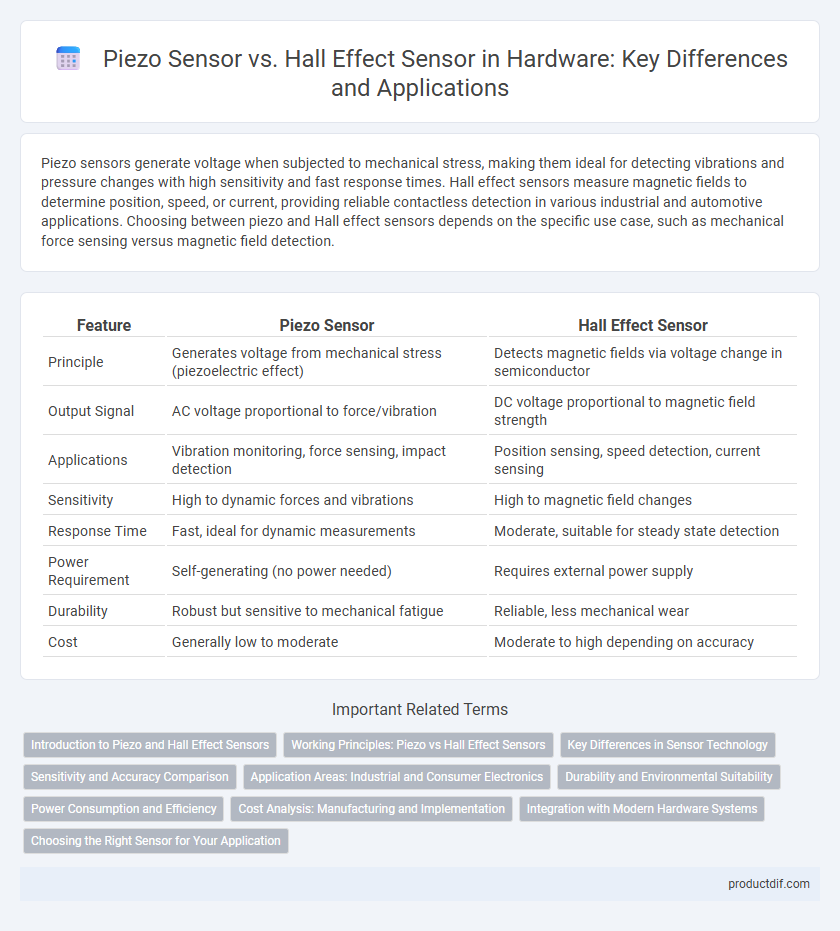

Table of Comparison

| Feature | Piezo Sensor | Hall Effect Sensor |

|---|---|---|

| Principle | Generates voltage from mechanical stress (piezoelectric effect) | Detects magnetic fields via voltage change in semiconductor |

| Output Signal | AC voltage proportional to force/vibration | DC voltage proportional to magnetic field strength |

| Applications | Vibration monitoring, force sensing, impact detection | Position sensing, speed detection, current sensing |

| Sensitivity | High to dynamic forces and vibrations | High to magnetic field changes |

| Response Time | Fast, ideal for dynamic measurements | Moderate, suitable for steady state detection |

| Power Requirement | Self-generating (no power needed) | Requires external power supply |

| Durability | Robust but sensitive to mechanical fatigue | Reliable, less mechanical wear |

| Cost | Generally low to moderate | Moderate to high depending on accuracy |

Introduction to Piezo and Hall Effect Sensors

Piezo sensors convert mechanical pressure or vibrations into electrical signals using the piezoelectric effect, making them ideal for detecting dynamic changes such as force, acceleration, and sound vibrations. Hall effect sensors operate by measuring the voltage generated across a conductor when exposed to a magnetic field, enabling precise detection of position, speed, and current. Both sensors are widely used in industrial, automotive, and consumer electronics applications due to their reliability and accuracy in detecting physical changes.

Working Principles: Piezo vs Hall Effect Sensors

Piezo sensors operate by generating an electrical charge in response to mechanical stress through the piezoelectric effect, making them ideal for detecting vibrations and pressure changes. Hall effect sensors function by measuring the voltage difference created when a magnetic field interacts with a current-carrying conductor, enabling precise detection of magnetic field strength and proximity. The fundamental difference lies in their transduction mechanisms: piezo sensors convert mechanical energy directly into electrical signals, while Hall effect sensors rely on magnetic field interactions to produce measurable voltage variations.

Key Differences in Sensor Technology

Piezo sensors detect changes in mechanical stress by converting pressure or vibration into an electrical charge, making them ideal for dynamic force or acceleration measurements. Hall effect sensors measure magnetic fields by detecting voltage variations caused by the Hall effect, primarily used for position, speed, or proximity sensing. The key difference lies in their sensing mechanism: piezo sensors respond to mechanical deformation while Hall effect sensors respond to magnetic flux changes.

Sensitivity and Accuracy Comparison

Piezo sensors exhibit high sensitivity to dynamic pressure changes due to their ability to convert mechanical stress into electrical charge, making them ideal for vibration and impact detection. Hall effect sensors provide precise and accurate measurements of magnetic fields with stable output, excelling in position and speed sensing applications. Sensitivity in piezo sensors often surpasses that of Hall effect sensors for dynamic events, whereas Hall effect sensors achieve greater accuracy for steady-state magnetic measurements.

Application Areas: Industrial and Consumer Electronics

Piezo sensors excel in industrial applications requiring precise pressure, vibration, and force measurements, such as machinery health monitoring and structural analysis, while in consumer electronics they are commonly used in touch-sensitive devices and audio equipment. Hall effect sensors are widely utilized in industrial automation for position sensing, speed detection, and current sensing due to their robustness and contactless operation, and in consumer electronics, they are found in smartphones for proximity detection and in brushless DC motors for efficient control. Both sensors serve critical roles in enhancing functionality and reliability across diverse industrial and consumer technologies.

Durability and Environmental Suitability

Piezo sensors exhibit high durability and excellent resistance to mechanical shock and vibration, making them ideal for harsh industrial environments and high-temperature applications. Hall effect sensors offer robust performance in dusty or wet conditions due to their solid-state design and lack of mechanical contact, which enhances longevity in outdoor or automotive settings. Both sensor types maintain reliability across diverse environments, but piezo sensors excel in extreme temperature tolerance while Hall effect sensors provide superior resistance to contamination and electromagnetic interference.

Power Consumption and Efficiency

Piezo sensors exhibit low power consumption by generating voltage from mechanical stress without requiring an external power source, making them highly efficient for energy harvesting applications. Hall effect sensors consume more power due to the continuous supply needed for their magnetic field detection but offer precise and stable measurements in static and dynamic conditions. Efficiency in power-sensitive designs favors piezo sensors for intermittent signals, while Hall effect sensors excel in continuous monitoring with consistent accuracy.

Cost Analysis: Manufacturing and Implementation

Piezo sensors generally offer lower manufacturing costs due to simpler materials and production processes compared to Hall effect sensors, which require precise semiconductor components. Implementation expenses for piezo sensors are reduced by minimal calibration and straightforward integration, whereas Hall effect sensors often incur higher costs linked to complex circuitry and shielding requirements. The overall cost-effectiveness of piezo sensors makes them preferred for budget-sensitive applications, while Hall effect sensors provide specialized functionality justifying their premium pricing.

Integration with Modern Hardware Systems

Piezo sensors offer high sensitivity and durability, making them ideal for vibration and pressure detection in compact devices, while Hall effect sensors excel in magnetic field detection with precise position and speed measurements in automotive and industrial applications. Integration of piezo sensors requires careful signal conditioning due to their high impedance, whereas Hall effect sensors benefit from straightforward digital interfaces compatible with microcontrollers and FPGA systems. Modern hardware designs increasingly favor Hall effect sensors for seamless integration with IoT and embedded control systems, though piezo sensors remain essential in specialized applications demanding analog signal nuance.

Choosing the Right Sensor for Your Application

Piezo sensors excel in detecting dynamic pressure changes and vibrations due to their high-frequency response and sensitivity, making them ideal for impact or acoustic monitoring applications. Hall effect sensors accurately measure magnetic fields and position, providing precise non-contact detection for rotary or linear motion in automotive and industrial systems. Selecting the right sensor depends on specific application requirements such as measurement type, environmental conditions, and response time.

Piezo sensor vs Hall effect sensor Infographic

productdif.com

productdif.com