Lead-free soldering uses alloys such as tin, silver, and copper to reduce environmental and health hazards associated with lead exposure, promoting safer manufacturing processes in electronics. Leaded soldering, typically composed of tin and lead, offers lower melting points and better wetting properties, resulting in strong, reliable joints preferred in high-performance hardware applications. Despite leaded solder's superior conductivity and ease of use, regulations like RoHS increasingly favor lead-free alternatives to ensure compliance and sustainability in hardware production.

Table of Comparison

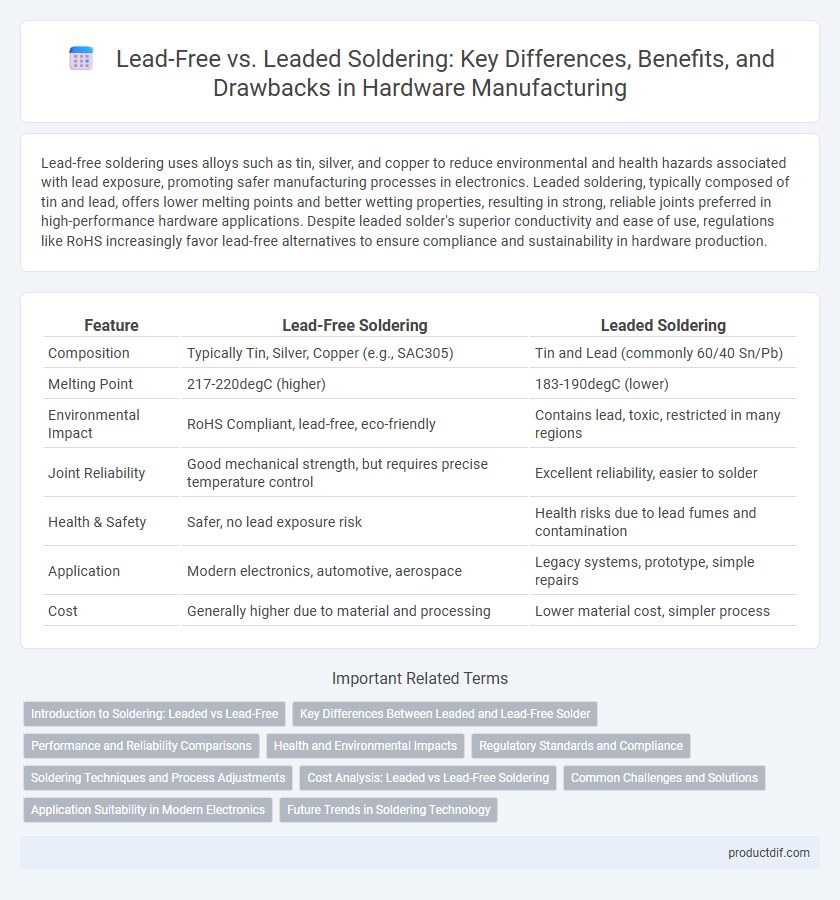

| Feature | Lead-Free Soldering | Leaded Soldering |

|---|---|---|

| Composition | Typically Tin, Silver, Copper (e.g., SAC305) | Tin and Lead (commonly 60/40 Sn/Pb) |

| Melting Point | 217-220degC (higher) | 183-190degC (lower) |

| Environmental Impact | RoHS Compliant, lead-free, eco-friendly | Contains lead, toxic, restricted in many regions |

| Joint Reliability | Good mechanical strength, but requires precise temperature control | Excellent reliability, easier to solder |

| Health & Safety | Safer, no lead exposure risk | Health risks due to lead fumes and contamination |

| Application | Modern electronics, automotive, aerospace | Legacy systems, prototype, simple repairs |

| Cost | Generally higher due to material and processing | Lower material cost, simpler process |

Introduction to Soldering: Leaded vs Lead-Free

Lead-free soldering uses alloys primarily composed of tin, silver, and copper, eliminating hazardous lead to meet environmental regulations like RoHS. Leaded soldering, containing about 60% tin and 40% lead, offers lower melting points and better wettability, making it simpler for traditional electronics assembly. Understanding the differences in thermal properties and environmental impact is crucial when selecting solder types for hardware manufacturing processes.

Key Differences Between Leaded and Lead-Free Solder

Leaded solder contains tin and lead, typically in a 60/40 ratio, offering lower melting points around 183degC and excellent electrical conductivity, making it easier for assembly and rework. Lead-free solder, often composed of tin, silver, and copper (SAC), melts at higher temperatures near 217degC, improving environmental safety but requiring precise temperature control during manufacturing. Key differences include thermal profile requirements, risk of solder joint brittleness, and regulatory compliance, especially with RoHS directives limiting lead use in electronic components.

Performance and Reliability Comparisons

Lead-free soldering typically offers improved environmental compliance but exhibits higher melting points, which can affect thermal stress on components compared to leaded soldering. Leaded soldering generally provides superior wetting properties and lower joint resistance, resulting in more reliable electrical connections under extreme conditions. Performance-wise, leaded solder joints often demonstrate better durability and fewer micro-cracks, enhancing long-term reliability in critical hardware applications.

Health and Environmental Impacts

Lead-free soldering reduces exposure to toxic lead fumes, significantly lowering health risks such as neurological damage and developmental issues in workers. Environmentally, lead-free solders prevent soil and water contamination caused by lead leaching, supporting safer waste disposal and recycling processes. Despite slightly higher melting points affecting energy consumption, lead-free alloys promote sustainable manufacturing by minimizing hazardous material usage.

Regulatory Standards and Compliance

Lead-free soldering complies with international regulations such as the Restriction of Hazardous Substances Directive (RoHS) and the Waste Electrical and Electronic Equipment Directive (WEEE), mandating reduced lead content to minimize environmental and health risks. Leaded soldering, while historically prevalent, faces increasing restrictions due to its toxicological impact and non-compliance with these modern environmental standards. Manufacturers must ensure soldering processes meet regional regulatory standards to maintain product safety certifications and market access.

Soldering Techniques and Process Adjustments

Lead-free soldering requires higher temperatures, typically around 217-221degC, compared to leaded soldering which melts at approximately 183degC, necessitating adjustments in heat settings and soldering iron calibration. The absence of lead affects the solder's wetting properties and flow, compelling modifications in flux composition and soldering duration to ensure reliable joint formation. Process adjustments also include using more heat-resistant components and optimizing cooling rates to prevent thermal stress and maintain solder joint integrity.

Cost Analysis: Leaded vs Lead-Free Soldering

Lead-free soldering typically incurs higher material costs due to the use of expensive metals like silver and bismuth, resulting in a 20-30% price increase compared to traditional leaded solder. Equipment modifications and increased process temperatures elevate energy consumption and maintenance expenses in lead-free soldering operations. Despite upfront costs, lead-free soldering reduces long-term environmental compliance fees and health-related liabilities associated with lead toxicity in manufacturing.

Common Challenges and Solutions

Lead-free soldering often presents challenges such as higher melting points, increased brittleness, and potential reliability issues in electronic assemblies compared to leaded soldering. Solutions include optimizing reflow profiles, using advanced flux formulations, and selecting compatible alloy compositions like SAC305 to enhance joint strength and reduce defects. Employing rigorous quality control measures and thermal process adjustments ensures improved solder wettability and mitigates common failures such as cracking and poor adhesion.

Application Suitability in Modern Electronics

Lead-free soldering is preferred in modern electronics due to its compliance with environmental regulations like RoHS, offering suitable performance for consumer devices and portable gadgets. Leaded soldering remains favored in applications requiring high reliability and strong mechanical bonds, such as aerospace and military electronics, due to its lower melting point and better wetting properties. Choosing between lead-free and leaded soldering depends on application-specific requirements including thermal performance, environmental impact, and long-term durability.

Future Trends in Soldering Technology

Future trends in soldering technology emphasize the increasing adoption of lead-free soldering due to environmental regulations like RoHS and WEEE, promoting safer electronic manufacturing processes. Advancements in lead-free alloys, such as SAC (tin-silver-copper) variants, aim to improve mechanical reliability and thermal performance while minimizing void formation and copper dissolution. Emerging technologies like conductive adhesives and low-temperature solder pastes are being developed to further enhance energy efficiency and compatibility with sensitive electronic components.

Lead-Free Soldering vs Leaded Soldering Infographic

productdif.com

productdif.com