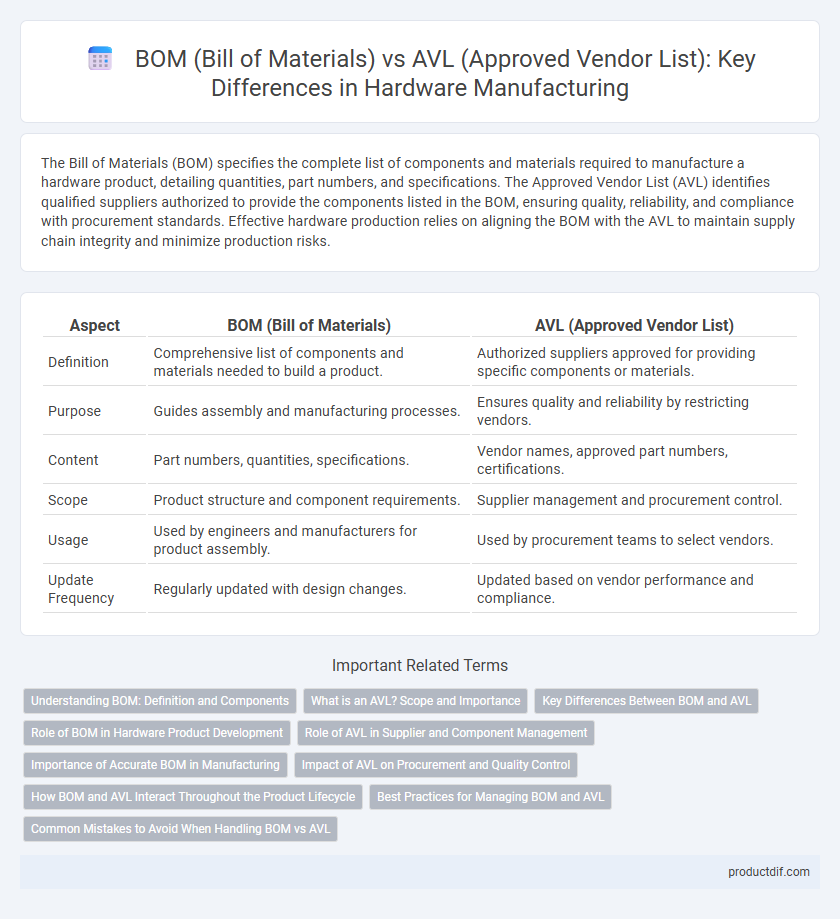

The Bill of Materials (BOM) specifies the complete list of components and materials required to manufacture a hardware product, detailing quantities, part numbers, and specifications. The Approved Vendor List (AVL) identifies qualified suppliers authorized to provide the components listed in the BOM, ensuring quality, reliability, and compliance with procurement standards. Effective hardware production relies on aligning the BOM with the AVL to maintain supply chain integrity and minimize production risks.

Table of Comparison

| Aspect | BOM (Bill of Materials) | AVL (Approved Vendor List) |

|---|---|---|

| Definition | Comprehensive list of components and materials needed to build a product. | Authorized suppliers approved for providing specific components or materials. |

| Purpose | Guides assembly and manufacturing processes. | Ensures quality and reliability by restricting vendors. |

| Content | Part numbers, quantities, specifications. | Vendor names, approved part numbers, certifications. |

| Scope | Product structure and component requirements. | Supplier management and procurement control. |

| Usage | Used by engineers and manufacturers for product assembly. | Used by procurement teams to select vendors. |

| Update Frequency | Regularly updated with design changes. | Updated based on vendor performance and compliance. |

Understanding BOM: Definition and Components

A Bill of Materials (BOM) is a comprehensive list detailing all raw materials, components, and assemblies required to manufacture a product. It includes part numbers, quantities, descriptions, and specifications essential for production planning and inventory management. Understanding BOM components ensures accurate procurement and efficient manufacturing processes in hardware development.

What is an AVL? Scope and Importance

An Approved Vendor List (AVL) is a curated catalog of suppliers authorized to provide components for manufacturing, ensuring quality and compliance with project specifications. It plays a crucial role in procurement by streamlining sourcing decisions, reducing risks associated with supply chain variability, and maintaining product consistency. The AVL's scope typically includes vendor evaluation based on certifications, past performance, and compatibility with the Bill of Materials (BOM) to optimize cost, lead time, and quality standards.

Key Differences Between BOM and AVL

The Bill of Materials (BOM) is a comprehensive list detailing all components, parts, and assemblies required to manufacture a product, including quantities and specifications. The Approved Vendor List (AVL) identifies specific suppliers or manufacturers authorized to provide each component, ensuring quality and compliance standards are met. While BOM defines what is needed, AVL dictates where components must be sourced from, emphasizing supplier reliability and supply chain management.

Role of BOM in Hardware Product Development

The Bill of Materials (BOM) serves as a comprehensive inventory listing all components, parts, and assemblies required for hardware product development, ensuring accurate resource planning and cost estimation. It functions as a blueprint that guides procurement, manufacturing, and quality control by specifying quantities, part numbers, and detailed descriptions. Unlike the Approved Vendor List (AVL), which restricts sourcing to pre-qualified suppliers, the BOM provides the foundational structure that drives design realization and facilitates efficient project management throughout the hardware development lifecycle.

Role of AVL in Supplier and Component Management

The Approved Vendor List (AVL) plays a crucial role in supplier and component management by ensuring that only pre-qualified, reliable vendors are selected for the Bill of Materials (BOM), thereby minimizing risks associated with supply chain disruptions and component obsolescence. AVL streamlines procurement by providing a vetted portfolio of suppliers that meet quality, compliance, and performance standards, which improves consistency and reduces procurement lead times. Effective AVL management supports cost control and enhances product lifecycle support by maintaining a dynamic list that reflects current market conditions and supplier capabilities.

Importance of Accurate BOM in Manufacturing

Accurate Bill of Materials (BOM) ensures precise component specifications and quantities, reducing manufacturing errors and production delays. It streamlines procurement by aligning with the Approved Vendor List (AVL) to source certified parts, minimizing quality risks and supply chain disruptions. Maintaining a detailed BOM enables efficient cost management and supports product lifecycle traceability in hardware manufacturing.

Impact of AVL on Procurement and Quality Control

The Approved Vendor List (AVL) critically streamlines procurement in hardware manufacturing by ensuring that components meet predefined quality standards and compatibility requirements outlined in the Bill of Materials (BOM). Utilizing an AVL reduces supply chain risks and minimizes variability, leading to consistent product performance and lower defect rates. Integration of AVL with BOM data enhances supplier traceability and facilitates more effective quality control processes throughout production cycles.

How BOM and AVL Interact Throughout the Product Lifecycle

BOM (Bill of Materials) outlines the complete list of components required for product assembly, serving as the foundation for manufacturing planning and cost estimation. AVL (Approved Vendor List) specifies authorized suppliers for each component in the BOM, ensuring quality control and supply chain reliability. Throughout the product lifecycle, synchronization between BOM and AVL is critical to manage component substitutions, mitigate supply risks, and maintain product integrity during design changes and production scaling.

Best Practices for Managing BOM and AVL

Effective management of BOM (Bill of Materials) and AVL (Approved Vendor List) ensures streamlined procurement and production processes in hardware manufacturing. Maintaining an accurate BOM with detailed component specifications combined with a regularly updated AVL featuring vetted and compliant suppliers minimizes supply chain risks and enhances product quality. Integrating BOM and AVL data through centralized software tools promotes traceability, reduces lead times, and supports regulatory compliance for optimal hardware lifecycle management.

Common Mistakes to Avoid When Handling BOM vs AVL

Confusing BOM (Bill of Materials) with AVL (Approved Vendor List) can lead to procurement errors, as BOM specifies required components while AVL lists authorized suppliers. Overlooking updates in either document may cause sourcing delays and usage of unauthorized parts, impacting product quality and compliance. Ensuring precise alignment between BOM components and AVL vendors minimizes supply chain disruptions and maintains manufacturing accuracy.

BOM (Bill of Materials) vs AVL (Approved Vendor List) Infographic

productdif.com

productdif.com