Copper traces offer superior electrical conductivity and thermal performance compared to aluminum traces, making them ideal for high-performance hardware projects. Copper's higher resistance to corrosion and better mechanical strength ensure longer-lasting and more reliable circuit functionality. Although aluminum traces are lighter and cost-effective, copper remains the preferred choice for precision and durability in PCB design.

Table of Comparison

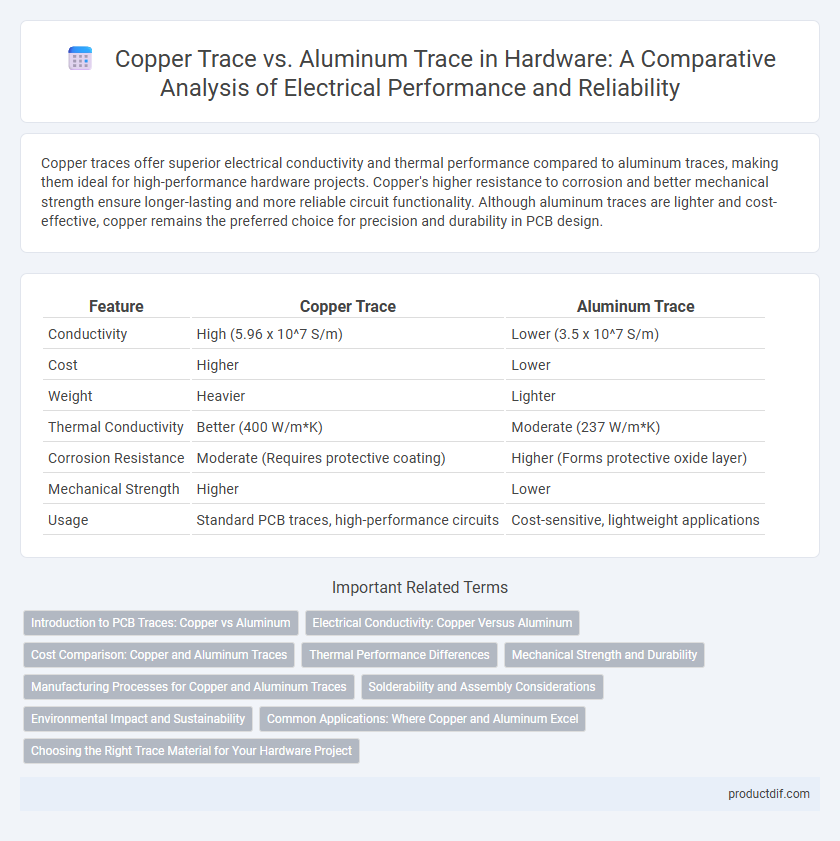

| Feature | Copper Trace | Aluminum Trace |

|---|---|---|

| Conductivity | High (5.96 x 10^7 S/m) | Lower (3.5 x 10^7 S/m) |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Thermal Conductivity | Better (400 W/m*K) | Moderate (237 W/m*K) |

| Corrosion Resistance | Moderate (Requires protective coating) | Higher (Forms protective oxide layer) |

| Mechanical Strength | Higher | Lower |

| Usage | Standard PCB traces, high-performance circuits | Cost-sensitive, lightweight applications |

Introduction to PCB Traces: Copper vs Aluminum

Copper traces in PCBs offer superior electrical conductivity and thermal performance, making them the industry standard for high-reliability electronics. Aluminum traces provide a lightweight, cost-effective alternative with good corrosion resistance but lower conductivity, often used in specific applications like LED boards. Choosing between copper and aluminum traces depends on factors such as electrical requirements, thermal management, and budget constraints.

Electrical Conductivity: Copper Versus Aluminum

Copper traces exhibit significantly higher electrical conductivity than aluminum traces, with copper's conductivity approximately 59.6 MS/m compared to aluminum's 37.8 MS/m at room temperature. This superior conductivity allows copper traces to carry higher current densities with less resistive loss and reduced heat generation, making them ideal for high-performance printed circuit boards (PCBs). Despite aluminum's lighter weight and lower cost, copper's electrical efficiency often justifies its use in applications demanding optimal signal integrity and minimal power dissipation.

Cost Comparison: Copper and Aluminum Traces

Copper traces generally incur higher material and manufacturing costs due to their superior conductivity and durability in PCB applications. Aluminum traces, while more cost-effective and lightweight, require thicker layers to achieve comparable electrical performance, potentially offsetting initial savings. Evaluating total cost involves balancing copper's efficiency with aluminum's affordability and weight advantages in hardware design.

Thermal Performance Differences

Copper traces exhibit superior thermal conductivity compared to aluminum traces, typically around 385 W/m*K for copper versus 205 W/m*K for aluminum, enabling more efficient heat dissipation in electronic circuits. This enhanced thermal performance reduces the risk of overheating and improves the reliability and lifespan of printed circuit boards (PCBs). Due to copper's higher melting point and thermal stability, it remains the preferred material for high-power and high-temperature hardware applications.

Mechanical Strength and Durability

Copper traces exhibit superior mechanical strength and durability compared to aluminum traces due to copper's higher tensile strength and enhanced resistance to thermal fatigue. The intrinsic properties of copper reduce the risk of micro-cracking and deformation under mechanical stress, ensuring longer-lasting performance in PCB applications. Aluminum traces, while lighter and cost-effective, are more prone to mechanical wear and thermal expansion issues, limiting their use in high-reliability hardware environments.

Manufacturing Processes for Copper and Aluminum Traces

Copper traces in PCB manufacturing require precision etching and plating processes due to copper's excellent electrical conductivity and thermal performance, allowing for fine line widths and high-density circuit designs. Aluminum traces involve different fabrication techniques such as sputtering or vapor deposition, favored for cost-effective, lightweight applications but generally offering lower conductivity and simpler patterning than copper. Manufacturing copper traces typically demands more sophisticated equipment and higher material costs, whereas aluminum traces benefit from lower materials expenses and faster processing but compromise on electrical performance and durability.

Solderability and Assembly Considerations

Copper traces exhibit superior solderability due to their stable oxide layer that can be easily removed during the soldering process, ensuring strong and reliable joints. Aluminum traces often require specialized surface treatments like nickel or silver plating to enhance solderability, as native aluminum oxide prevents proper solder adhesion. Assembly considerations favor copper traces for conventional PCB manufacturing, whereas aluminum traces are more challenging and typically reserved for specific applications like high-current or lightweight designs.

Environmental Impact and Sustainability

Copper traces in hardware manufacturing offer superior recyclability and lower energy consumption during processing compared to aluminum traces, which require more intensive mining and refining processes with higher carbon emissions. Copper's longer lifecycle and higher conductivity contribute to greater overall sustainability by reducing electronic waste and enhancing device efficiency. Although aluminum is lighter and less expensive, its environmental footprint is typically higher due to limited recyclability and greater ecological disruption during extraction.

Common Applications: Where Copper and Aluminum Excel

Copper traces dominate in high-frequency and high-current PCB applications due to their superior electrical conductivity and thermal performance, making them ideal for aerospace, automotive, and consumer electronics. Aluminum traces, with lower cost and lighter weight, excel in power distribution and LED lighting systems where moderate conductivity suffices and heat dissipation is crucial. Both materials find niche uses based on balancing performance, cost, and mechanical requirements in electronic hardware design.

Choosing the Right Trace Material for Your Hardware Project

Copper trace offers superior electrical conductivity, reliability, and thermal performance compared to aluminum trace, making it the preferred choice for high-density and high-frequency hardware projects. Aluminum trace, while lighter and more cost-effective, has higher resistance and is prone to oxidation, limiting its use in precision circuits and demanding environments. Selecting copper trace ensures enhanced signal integrity and durability, critical factors for advanced electronic designs and long-term hardware performance.

Copper trace vs Aluminum trace Infographic

productdif.com

productdif.com