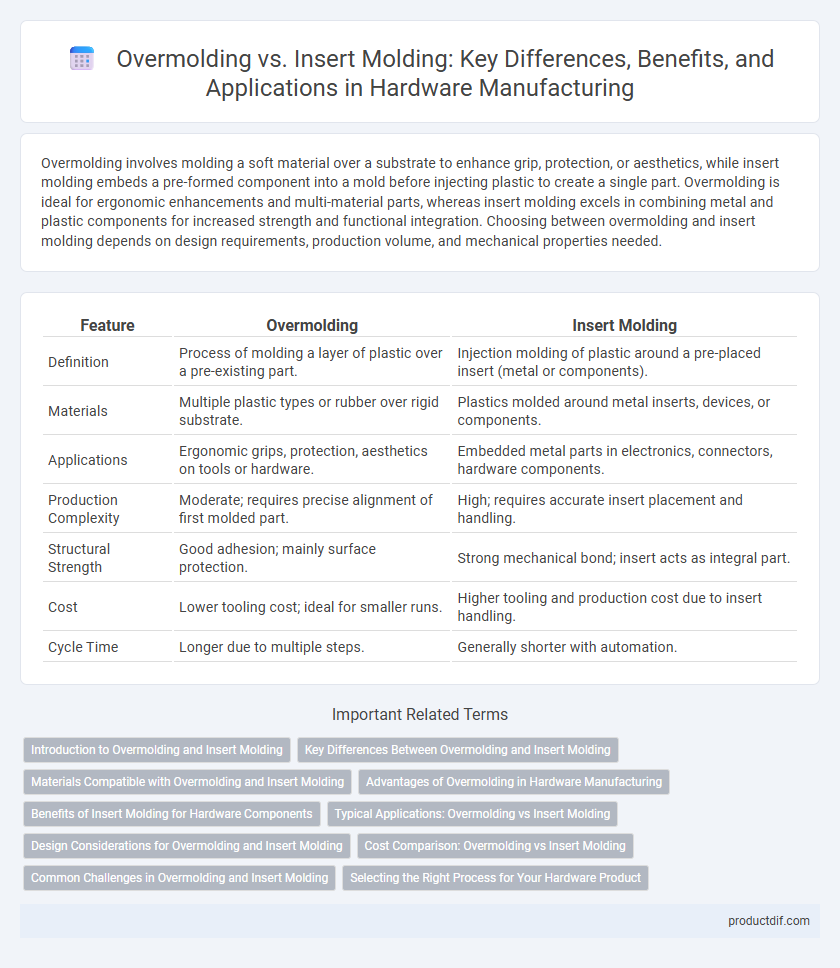

Overmolding involves molding a soft material over a substrate to enhance grip, protection, or aesthetics, while insert molding embeds a pre-formed component into a mold before injecting plastic to create a single part. Overmolding is ideal for ergonomic enhancements and multi-material parts, whereas insert molding excels in combining metal and plastic components for increased strength and functional integration. Choosing between overmolding and insert molding depends on design requirements, production volume, and mechanical properties needed.

Table of Comparison

| Feature | Overmolding | Insert Molding |

|---|---|---|

| Definition | Process of molding a layer of plastic over a pre-existing part. | Injection molding of plastic around a pre-placed insert (metal or components). |

| Materials | Multiple plastic types or rubber over rigid substrate. | Plastics molded around metal inserts, devices, or components. |

| Applications | Ergonomic grips, protection, aesthetics on tools or hardware. | Embedded metal parts in electronics, connectors, hardware components. |

| Production Complexity | Moderate; requires precise alignment of first molded part. | High; requires accurate insert placement and handling. |

| Structural Strength | Good adhesion; mainly surface protection. | Strong mechanical bond; insert acts as integral part. |

| Cost | Lower tooling cost; ideal for smaller runs. | Higher tooling and production cost due to insert handling. |

| Cycle Time | Longer due to multiple steps. | Generally shorter with automation. |

Introduction to Overmolding and Insert Molding

Overmolding involves molding a soft material over a pre-existing rigid part to enhance grip, comfort, or aesthetics, often used in tools and electronic device casings. Insert molding integrates metal or other inserts directly into plastic components during the molding process, improving structural strength and assembly efficiency in automotive and medical hardware. Both techniques optimize product functionality by combining materials in advanced manufacturing processes.

Key Differences Between Overmolding and Insert Molding

Overmolding involves molding a soft material over a substrate or existing part, enhancing grip, durability, and aesthetics, while insert molding embeds metal or plastic inserts into an injection-molded part to provide structural strength and precise component placement. Overmolding typically uses multiple materials with different properties in layers, whereas insert molding integrates solid inserts during the molding process for seamless bonding. The key difference lies in overmolding's focus on adding functional and ergonomic features versus insert molding's aim at combining components for mechanical and electrical functionality.

Materials Compatible with Overmolding and Insert Molding

Overmolding primarily uses thermoplastic materials such as TPE, TPU, and ABS, which provide excellent adhesion and flexibility when molded over a substrate, often a harder plastic like PC or nylon. Insert molding employs materials like polypropylene, polycarbonate, and glass-filled nylon that can withstand high injection pressures and temperatures to encapsulate metal or other inserts securely. Both techniques require material combinations with compatible melt temperatures and chemical properties to ensure strong bonds and functional durability.

Advantages of Overmolding in Hardware Manufacturing

Overmolding in hardware manufacturing enhances product durability by providing superior bonding between different materials, resulting in improved mechanical strength and resistance to environmental factors. This process allows the integration of multiple components in a single unit, reducing assembly time and minimizing production costs. Overmolding also offers enhanced design flexibility, enabling manufacturers to create ergonomic and aesthetically appealing hardware with varied textures and colors.

Benefits of Insert Molding for Hardware Components

Insert molding enhances the durability of hardware components by securely embedding metal parts within a plastic matrix, reducing the risk of component loosening or failure. This process offers superior strength and precision, ensuring consistent alignment and electrical insulation for complex assemblies. It also streamlines production by combining multiple parts into a single unit, cutting down assembly time and costs while improving overall product reliability.

Typical Applications: Overmolding vs Insert Molding

Overmolding is commonly used in producing ergonomic tools, medical devices, and electronic housings where soft-touch or multi-material components enhance user comfort and functionality. Insert molding is ideal for integrating metal fasteners or electronic components within plastic parts, such as automotive connectors, sensors, and consumer electronics, providing durable mechanical bonds and precise assembly. Both methods improve product performance but are selected based on application requirements like material compatibility and structural complexity.

Design Considerations for Overmolding and Insert Molding

Design considerations for overmolding include ensuring compatible materials with distinct thermal properties and adequate surface adhesion to prevent delamination, while maintaining precise mold tolerances for consistent part fit. Insert molding requires attention to the placement and stability of metal or plastic inserts within the mold, as well as controlling the molding pressure and temperature to avoid deformation or displacement of the inserts. Both processes demand careful evaluation of component geometry, material compatibility, and post-molding functionality to achieve optimal performance and durability.

Cost Comparison: Overmolding vs Insert Molding

Overmolding typically incurs higher initial tool and mold costs but offers lower per-unit expenses in large production runs due to its integrated manufacturing process. Insert molding involves placing pre-made components into a mold, leading to increased manual labor and assembly costs, which can raise overall expenses for high-volume production. Businesses aiming for cost efficiency in mass manufacturing often prefer overmolding, while insert molding may be more economical for low-volume or complex component assemblies.

Common Challenges in Overmolding and Insert Molding

Common challenges in overmolding include maintaining strong adhesion between substrates and overmold materials, managing differential shrinkage rates, and ensuring precise alignment of molded layers to prevent defects. Insert molding faces difficulties such as securely holding inserts in place during molding, avoiding insert displacement, and mitigating thermal stresses that can cause warping or cracking of components. Both processes require careful control of molding parameters and material compatibility to achieve high-quality, durable parts in hardware manufacturing.

Selecting the Right Process for Your Hardware Product

Choosing between overmolding and insert molding depends on the specific requirements of your hardware product, such as durability, complexity, and production volume. Overmolding excels in creating ergonomic grips and enhanced aesthetics by molding soft materials over rigid substrates, while insert molding integrates metal or plastic components directly during the injection molding process for increased strength and precise assembly. Evaluating factors like material compatibility, mechanical stress, and cost-effectiveness is crucial to selecting the ideal molding technique for optimized performance and manufacturing efficiency.

Overmolding vs Insert Molding Infographic

productdif.com

productdif.com