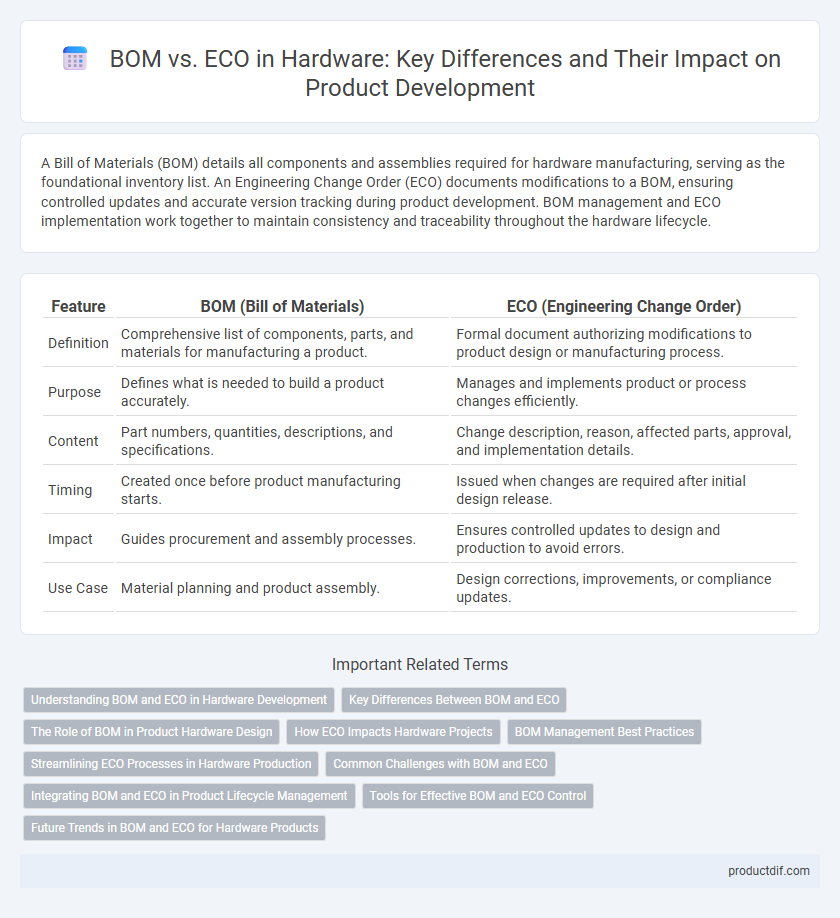

A Bill of Materials (BOM) details all components and assemblies required for hardware manufacturing, serving as the foundational inventory list. An Engineering Change Order (ECO) documents modifications to a BOM, ensuring controlled updates and accurate version tracking during product development. BOM management and ECO implementation work together to maintain consistency and traceability throughout the hardware lifecycle.

Table of Comparison

| Feature | BOM (Bill of Materials) | ECO (Engineering Change Order) |

|---|---|---|

| Definition | Comprehensive list of components, parts, and materials for manufacturing a product. | Formal document authorizing modifications to product design or manufacturing process. |

| Purpose | Defines what is needed to build a product accurately. | Manages and implements product or process changes efficiently. |

| Content | Part numbers, quantities, descriptions, and specifications. | Change description, reason, affected parts, approval, and implementation details. |

| Timing | Created once before product manufacturing starts. | Issued when changes are required after initial design release. |

| Impact | Guides procurement and assembly processes. | Ensures controlled updates to design and production to avoid errors. |

| Use Case | Material planning and product assembly. | Design corrections, improvements, or compliance updates. |

Understanding BOM and ECO in Hardware Development

Bill of Materials (BOM) in hardware development is a comprehensive list of raw materials, components, and assemblies required to construct a product, detailing part numbers, quantities, and specifications. Engineering Change Orders (ECO) are formal documents that authorize and specify modifications to the BOM or design to address issues, improve performance, or incorporate new features. Understanding the interplay between BOM and ECO ensures accurate product documentation, efficient change management, and streamlined manufacturing processes.

Key Differences Between BOM and ECO

The Bill of Materials (BOM) is a comprehensive list of raw materials, components, and assemblies required to manufacture a product, detailing quantities and specifications. Engineering Change Orders (ECO) are formal documents authorized to modify the existing BOM or design, addressing issues like design flaws, cost reduction, or component substitutions. Key differences include the BOM serving as the baseline material recipe for production, while the ECO functions as a controlled process for implementing and documenting changes within that baseline.

The Role of BOM in Product Hardware Design

The Bill of Materials (BOM) in product hardware design serves as a comprehensive list of all components, parts, and materials required for manufacturing a device, ensuring precise inventory and procurement management. It provides essential data for cost estimation, production planning, and quality control throughout the hardware development lifecycle. Effective BOM management facilitates seamless integration with Engineering Change Orders (ECO), enabling controlled updates to design specifications while maintaining product consistency.

How ECO Impacts Hardware Projects

Engineering Change Orders (ECOs) directly modify the Bill of Materials (BOM) by updating component specifications, quantities, or suppliers to address design improvements or manufacturing issues. ECOs impact hardware projects by introducing revisions that can alter production schedules, increase costs, and require requalification of materials and assemblies. Effective management of ECOs ensures hardware projects maintain quality standards while adapting to necessary changes in the BOM.

BOM Management Best Practices

Effective BOM management involves maintaining an accurate and up-to-date Bill of Materials to streamline production and minimize errors. Implementing version control and change tracking ensures any Engineering Change Orders (ECOs) are clearly reflected and integrated without disrupting the manufacturing process. Leveraging BOM management software aids in real-time collaboration between design, procurement, and production teams, enhancing data accuracy and reducing time-to-market.

Streamlining ECO Processes in Hardware Production

Streamlining Engineering Change Order (ECO) processes in hardware production reduces errors and accelerates time-to-market by enabling precise Bill of Materials (BOM) updates. Integrating automated BOM management systems ensures real-time tracking of component changes, minimizing rework and inventory discrepancies. Efficient ECO workflows enhance collaboration between design, procurement, and manufacturing teams, optimizing production schedules and cost control.

Common Challenges with BOM and ECO

Common challenges with Bill of Materials (BOM) and Engineering Change Orders (ECO) include maintaining accurate version control and synchronizing updates between design teams and manufacturing. Inconsistent data in BOMs often leads to production delays, increased costs, and inventory discrepancies. ECO processes can be hindered by inadequate communication workflows, causing errors in part substitutions and delayed implementation of design changes.

Integrating BOM and ECO in Product Lifecycle Management

Integrating Bill of Materials (BOM) and Engineering Change Orders (ECO) within Product Lifecycle Management (PLM) enhances accuracy in product revisions and streamlines communication across design, manufacturing, and supply chain teams. A unified BOM-ECO approach enables real-time updates, reduces errors in component sourcing, and accelerates time-to-market by maintaining synchronized data throughout product development stages. Advanced PLM systems leverage this integration to improve change traceability, optimize inventory management, and support regulatory compliance for complex hardware products.

Tools for Effective BOM and ECO Control

Effective BOM and ECO control relies heavily on specialized software tools such as IBM Engineering Lifecycle Management and Arena PLM, which streamline bill of materials accuracy and change management. These platforms enable real-time collaboration, version control, and comprehensive change tracking to reduce errors and enhance productivity. Integrating these tools with enterprise resource planning (ERP) systems further ensures synchronized updates across manufacturing and procurement processes.

Future Trends in BOM and ECO for Hardware Products

Future trends in Bill of Materials (BOM) and Engineering Change Orders (ECO) for hardware products emphasize increased automation and integration with digital twins to streamline design modifications and supply chain management. Advanced AI-driven analytics enable predictive adjustments in BOM, reducing lead times and material costs, while blockchain technology enhances transparency and traceability of ECO implementations. The convergence of IoT and cloud platforms facilitates real-time collaboration between engineering teams, suppliers, and manufacturers, accelerating innovation cycles and minimizing production errors.

BOM vs ECO Infographic

productdif.com

productdif.com