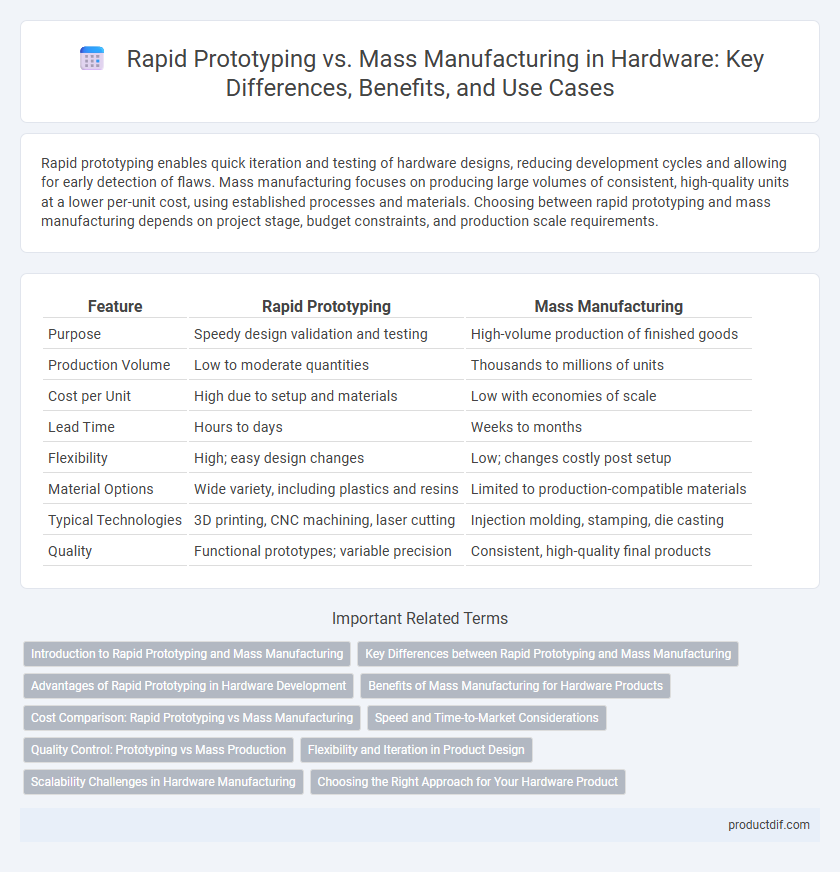

Rapid prototyping enables quick iteration and testing of hardware designs, reducing development cycles and allowing for early detection of flaws. Mass manufacturing focuses on producing large volumes of consistent, high-quality units at a lower per-unit cost, using established processes and materials. Choosing between rapid prototyping and mass manufacturing depends on project stage, budget constraints, and production scale requirements.

Table of Comparison

| Feature | Rapid Prototyping | Mass Manufacturing |

|---|---|---|

| Purpose | Speedy design validation and testing | High-volume production of finished goods |

| Production Volume | Low to moderate quantities | Thousands to millions of units |

| Cost per Unit | High due to setup and materials | Low with economies of scale |

| Lead Time | Hours to days | Weeks to months |

| Flexibility | High; easy design changes | Low; changes costly post setup |

| Material Options | Wide variety, including plastics and resins | Limited to production-compatible materials |

| Typical Technologies | 3D printing, CNC machining, laser cutting | Injection molding, stamping, die casting |

| Quality | Functional prototypes; variable precision | Consistent, high-quality final products |

Introduction to Rapid Prototyping and Mass Manufacturing

Rapid prototyping leverages technologies such as 3D printing and CNC machining to quickly produce physical models and functional parts, enabling iterative design testing and validation. Mass manufacturing employs processes like injection molding and automated assembly lines to efficiently produce large volumes of consistent, high-quality hardware components at scale. Understanding the distinct advantages of rapid prototyping for flexibility and speed versus mass manufacturing for cost efficiency and uniformity is essential in hardware development cycles.

Key Differences between Rapid Prototyping and Mass Manufacturing

Rapid prototyping allows for quick iteration and design validation using additive manufacturing methods, while mass manufacturing focuses on high-volume production through established processes like injection molding. Rapid prototyping incurs higher per-unit costs but reduces time-to-market and enables early detection of design flaws. Mass manufacturing achieves economies of scale with lower per-unit costs but requires significant upfront tooling investment and longer lead times.

Advantages of Rapid Prototyping in Hardware Development

Rapid prototyping accelerates hardware development by enabling quick iteration and immediate testing of design concepts, reducing time-to-market significantly. This method minimizes production costs in early stages and allows for early detection of design flaws, which enhances product quality and functionality. It also supports customization and flexibility, allowing developers to adapt rapidly to changes in design requirements or user feedback.

Benefits of Mass Manufacturing for Hardware Products

Mass manufacturing offers significant cost advantages through economies of scale, reducing the per-unit cost of hardware products. It ensures consistent quality and precision by using standardized processes and automation, leading to reliable product performance. High production volumes enable faster market delivery and better inventory management compared to rapid prototyping.

Cost Comparison: Rapid Prototyping vs Mass Manufacturing

Rapid prototyping typically incurs higher per-unit costs due to lower production volumes and specialized materials, making it ideal for design validation and small batch testing. Mass manufacturing benefits from economies of scale, significantly reducing the cost per unit as production volume increases through processes like injection molding or CNC machining. Companies must balance initial investment and per-unit expenses when choosing between rapid prototyping and mass manufacturing for hardware production.

Speed and Time-to-Market Considerations

Rapid prototyping drastically reduces development time by enabling quick iterations and immediate testing, accelerating product validation compared to traditional methods. Mass manufacturing requires substantial setup time for tooling and processes, resulting in longer lead times before full-scale production begins. Prioritizing rapid prototyping shortens the time-to-market, allowing faster response to market demands and competitive pressures.

Quality Control: Prototyping vs Mass Production

Rapid prototyping enables early detection and resolution of design flaws through iterative testing, enhancing product quality before mass manufacturing begins. Mass manufacturing quality control relies on statistical process control (SPC) and automated inspection systems to ensure consistent output across large production volumes. Effective integration of prototyping feedback into mass production protocols significantly reduces defect rates and improves overall product reliability.

Flexibility and Iteration in Product Design

Rapid prototyping offers unmatched flexibility in product design, enabling engineers to quickly create and test multiple iterations with minimal cost and time investment. This process fosters innovation through continuous refinement and immediate feedback, unlike mass manufacturing which requires standardized, fixed designs to minimize production costs. While mass manufacturing excels in producing large volumes efficiently, it lacks the adaptability needed during early development stages where frequent design changes are critical.

Scalability Challenges in Hardware Manufacturing

Rapid prototyping excels in flexibility and swift design iterations but faces significant scalability limitations due to higher per-unit costs and slower production speeds compared to mass manufacturing. Mass manufacturing benefits from economies of scale, enabling cost-effective production of large volumes, yet requires substantial upfront investment in tooling and setup, making it less adaptable to design changes. Overcoming scalability challenges in hardware manufacturing involves balancing the agility of rapid prototyping with the efficiency of mass production to optimize costs and delivery timelines.

Choosing the Right Approach for Your Hardware Product

Rapid prototyping enables quick design validation and functional testing, significantly reducing development time and costs for hardware products. Mass manufacturing becomes cost-effective only after finalizing designs and achieving product consistency, allowing economies of scale and minimizing per-unit expenses. Selecting the right approach depends on project stage, production volume, budget constraints, and the critical need for iterative improvements during hardware development.

Rapid Prototyping vs Mass Manufacturing Infographic

productdif.com

productdif.com