Heat sinks rely on metal fins to dissipate heat through convection, making them effective for moderate thermal management in electronic devices. Vapor chambers utilize a sealed vacuum with a liquid that evaporates and condenses to transfer heat more efficiently across surfaces, offering superior performance in high-power applications. Choosing between heat sinks and vapor chambers depends on the device's cooling requirements, size constraints, and thermal load.

Table of Comparison

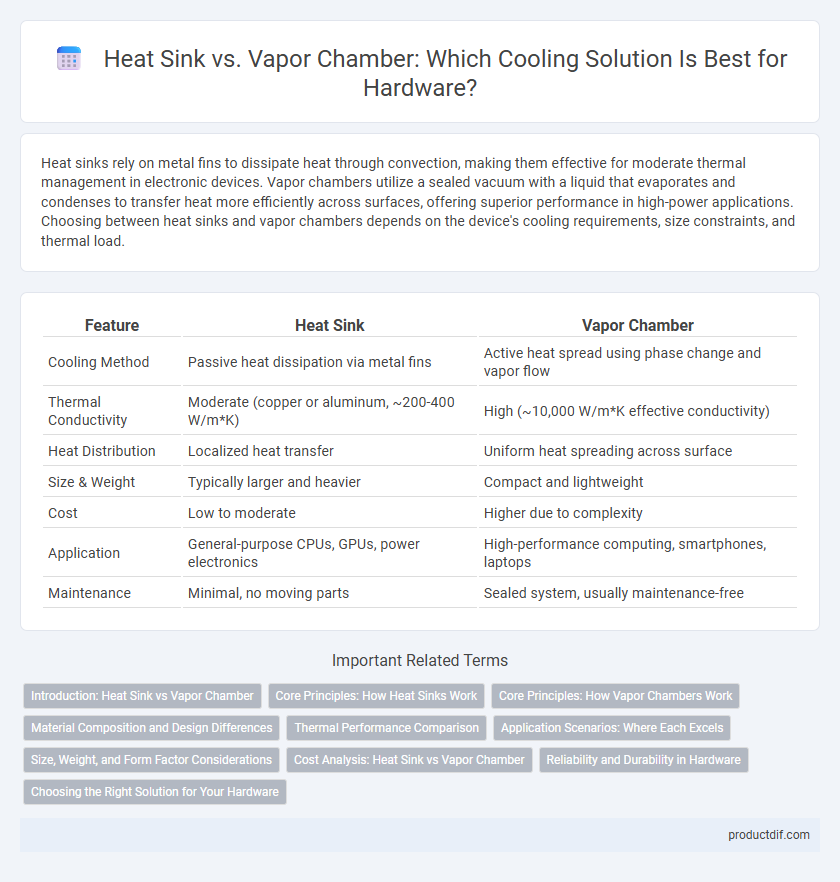

| Feature | Heat Sink | Vapor Chamber |

|---|---|---|

| Cooling Method | Passive heat dissipation via metal fins | Active heat spread using phase change and vapor flow |

| Thermal Conductivity | Moderate (copper or aluminum, ~200-400 W/m*K) | High (~10,000 W/m*K effective conductivity) |

| Heat Distribution | Localized heat transfer | Uniform heat spreading across surface |

| Size & Weight | Typically larger and heavier | Compact and lightweight |

| Cost | Low to moderate | Higher due to complexity |

| Application | General-purpose CPUs, GPUs, power electronics | High-performance computing, smartphones, laptops |

| Maintenance | Minimal, no moving parts | Sealed system, usually maintenance-free |

Introduction: Heat Sink vs Vapor Chamber

Heat sinks use metal fins to dissipate heat through conduction and convection, making them effective for moderate thermal management in computers and electronics. Vapor chambers employ phase-change technology to spread heat quickly across a flat surface, offering superior efficiency for high-performance CPUs and GPUs. Both solutions optimize thermal conductivity but differ in design complexity and cooling capacity.

Core Principles: How Heat Sinks Work

Heat sinks dissipate thermal energy by increasing surface area and enhancing airflow, transferring heat from the electronic component to the surrounding air through conduction and convection. They rely on materials with high thermal conductivity, such as aluminum or copper, to efficiently absorb and spread heat away from the heat source. Vapor chambers use phase-change cooling to distribute heat uniformly but heat sinks remain fundamental in passive cooling through direct heat conduction and airflow optimization.

Core Principles: How Vapor Chambers Work

Vapor chambers operate on the principle of phase change cooling, where a liquid inside the sealed chamber absorbs heat and evaporates, spreading thermal energy evenly across the surface. This vapor then condenses back to liquid on cooler areas of the chamber, releasing heat and maintaining efficient thermal regulation. Compared to traditional heat sinks, vapor chambers provide superior heat dissipation through this cycle of evaporation and condensation, enhancing performance in high-power electronics.

Material Composition and Design Differences

Heat sinks are typically composed of aluminum or copper to maximize thermal conductivity, featuring a finned design that increases surface area for efficient heat dissipation. Vapor chambers utilize a sealed copper or aluminum enclosure filled with a working fluid, leveraging phase-change heat transfer to distribute heat more uniformly across surfaces. The design of vapor chambers allows for thinner, more compact profiles compared to conventional heat sinks, offering superior thermal performance in high-density electronic applications.

Thermal Performance Comparison

Heat sinks dissipate heat through aluminum or copper fins by increasing surface area and promoting airflow, achieving effective cooling for moderate thermal loads. Vapor chambers provide superior thermal performance by utilizing phase-change technology to rapidly spread heat across a flat, highly conductive surface, minimizing hot spots in high-power devices. Vapor chambers excel in uniform heat distribution and faster heat transfer, making them ideal for high-performance electronics compared to traditional heat sinks.

Application Scenarios: Where Each Excels

Heat sinks excel in low to moderate heat dissipation scenarios commonly found in consumer electronics, desktops, and moderate-performance CPUs, offering cost-effective and reliable thermal management. Vapor chambers outperform heat sinks in high-performance applications such as gaming laptops, data centers, and advanced GPUs by providing superior heat spreading and uniform temperature distribution. Their advanced phase-change technology enables efficient cooling in compact designs where space and thermal conductivity are critical factors.

Size, Weight, and Form Factor Considerations

Heat sinks typically offer a larger size and heavier weight due to extensive fin structures designed for passive heat dissipation, making them less ideal for compact or lightweight devices. Vapor chambers provide a slimmer, lighter form factor by using a sealed, flat design that efficiently spreads heat over a larger surface area within tight spaces. These characteristics make vapor chambers preferable for modern, high-performance electronics where space and weight constraints are critical.

Cost Analysis: Heat Sink vs Vapor Chamber

Heat sinks typically offer a lower upfront cost, making them a cost-effective solution for standard cooling needs in consumer electronics. Vapor chambers, while more expensive initially, provide superior thermal performance and efficiency, potentially reducing long-term operational costs by enhancing device reliability and lifespan. The choice between heat sink and vapor chamber depends on balancing initial budget constraints against the benefits of improved heat dissipation and efficiency in high-performance applications.

Reliability and Durability in Hardware

Heat sinks offer reliable passive cooling through solid metal fins, providing consistent durability with minimal failure points in hardware applications. Vapor chambers deliver enhanced thermal performance by efficiently spreading heat over a larger surface area, though their reliability can be affected by potential vapor leakage and manufacturing complexity. In demanding hardware environments, heat sinks generally provide longer-lasting durability, while vapor chambers require careful design and quality control to ensure sustained reliability.

Choosing the Right Solution for Your Hardware

Heat sinks excel in passive cooling for low to moderate thermal loads with simpler design and cost-effectiveness, making them ideal for standard CPUs and GPUs. Vapor chambers offer superior heat spreading and efficiency in high-performance hardware where space constraints and thermal peaks demand advanced thermal management. Selecting the right solution depends on balancing thermal conductivity requirements, device size, and budget constraints to ensure optimal hardware performance and longevity.

Heat sink vs Vapor chamber Infographic

productdif.com

productdif.com