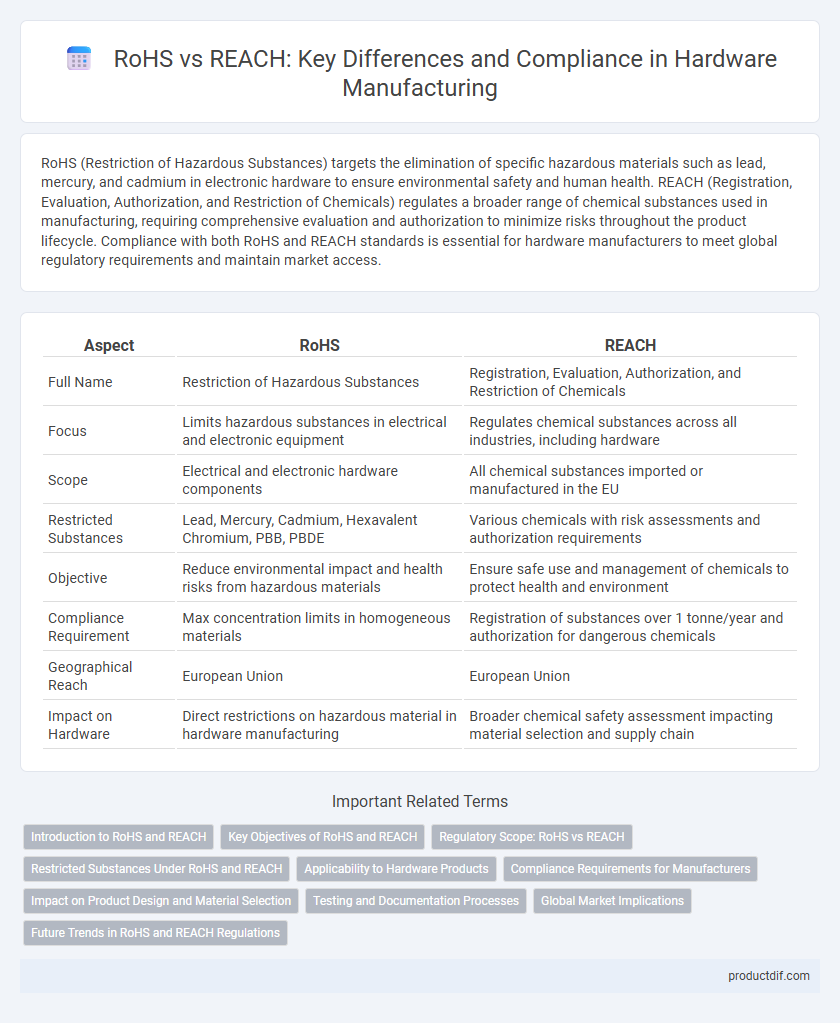

RoHS (Restriction of Hazardous Substances) targets the elimination of specific hazardous materials such as lead, mercury, and cadmium in electronic hardware to ensure environmental safety and human health. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulates a broader range of chemical substances used in manufacturing, requiring comprehensive evaluation and authorization to minimize risks throughout the product lifecycle. Compliance with both RoHS and REACH standards is essential for hardware manufacturers to meet global regulatory requirements and maintain market access.

Table of Comparison

| Aspect | RoHS | REACH |

|---|---|---|

| Full Name | Restriction of Hazardous Substances | Registration, Evaluation, Authorization, and Restriction of Chemicals |

| Focus | Limits hazardous substances in electrical and electronic equipment | Regulates chemical substances across all industries, including hardware |

| Scope | Electrical and electronic hardware components | All chemical substances imported or manufactured in the EU |

| Restricted Substances | Lead, Mercury, Cadmium, Hexavalent Chromium, PBB, PBDE | Various chemicals with risk assessments and authorization requirements |

| Objective | Reduce environmental impact and health risks from hazardous materials | Ensure safe use and management of chemicals to protect health and environment |

| Compliance Requirement | Max concentration limits in homogeneous materials | Registration of substances over 1 tonne/year and authorization for dangerous chemicals |

| Geographical Reach | European Union | European Union |

| Impact on Hardware | Direct restrictions on hazardous material in hardware manufacturing | Broader chemical safety assessment impacting material selection and supply chain |

Introduction to RoHS and REACH

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are critical European Union regulations targeting hazardous substances in hardware manufacturing. RoHS specifically restricts hazardous materials like lead, mercury, and cadmium in electrical and electronic equipment to reduce environmental and health risks. REACH oversees the registration and safe use of all chemical substances within the EU, ensuring that manufacturers disclose chemical risks in hardware components to protect human health and the environment.

Key Objectives of RoHS and REACH

RoHS (Restriction of Hazardous Substances) aims to limit hazardous materials like lead, mercury, cadmium, and hexavalent chromium in electronic and electrical equipment to reduce environmental and health risks. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) focuses on the safe use of chemical substances throughout their lifecycle, ensuring human health and environmental protection by regulating substances of very high concern (SVHC). Both regulations target sustainability and safety but differ in scope, with RoHS emphasizing hardware components and REACH covering a broader chemical management framework.

Regulatory Scope: RoHS vs REACH

RoHS (Restriction of Hazardous Substances) targets specific hazardous materials in electrical and electronic equipment, limiting substances like lead, mercury, and cadmium to reduce environmental and health risks. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) encompasses a broader regulatory scope, addressing the production and use of chemical substances across all industries, including raw materials and finished products. While RoHS focuses on substance restrictions to ensure compliance in electronic hardware, REACH manages the entire chemical lifecycle to safeguard human health and environmental safety.

Restricted Substances Under RoHS and REACH

RoHS restricts hazardous substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE) in electrical and electronic equipment. REACH targets a broader range of chemicals, including substances of very high concern (SVHC) like carcinogens, mutagens, and endocrine disruptors, often requiring registration and authorization for use in products. Compliance with RoHS ensures limited heavy metals and flame retardants, while REACH mandates comprehensive chemical safety data and controls across all industries, including hardware manufacturing.

Applicability to Hardware Products

RoHS restricts hazardous substances such as lead, mercury, and cadmium in electrical and electronic hardware products to ensure environmental safety and human health. REACH mandates the registration, evaluation, authorization, and restriction of chemical substances used broadly across hardware materials, including metals, plastics, and coatings. Compliance with both RoHS and REACH is critical for manufacturers aiming to market hardware devices within the European Union, driving adoption of safer and environmentally friendly components.

Compliance Requirements for Manufacturers

RoHS mandates the restriction of hazardous substances such as lead, mercury, and cadmium in electrical and electronic equipment, requiring manufacturers to ensure strict material composition compliance. REACH focuses on the registration, evaluation, and authorization of chemical substances, compelling manufacturers to provide detailed information on the chemical safety of substances used in hardware products. Both regulations necessitate comprehensive documentation and testing protocols to maintain compliance, minimize environmental impact, and avoid market restrictions in the European Union.

Impact on Product Design and Material Selection

RoHS restricts hazardous substances like lead, mercury, and cadmium in electronic products, forcing designers to select compliant, non-toxic materials that ensure safety and environmental standards are met. REACH regulates the registration and evaluation of chemical substances used in manufacturing, requiring thorough assessment of material safety and potential risks, impacting the choice of raw materials and additives. Together, RoHS and REACH drive innovation in eco-friendly component sourcing and influence engineering decisions to balance performance with regulatory compliance.

Testing and Documentation Processes

RoHS compliance testing focuses on detecting restricted hazardous substances like lead, mercury, and cadmium in hardware components to ensure environmental safety. REACH testing involves a broader analysis, identifying and documenting chemical substances potentially affecting human health and ecosystems, requiring detailed substance registration and safety data sheets. Comprehensive documentation for RoHS emphasizes certificates of compliance, while REACH demands extensive technical dossiers and ongoing chemical risk assessments.

Global Market Implications

RoHS restricts hazardous substances in electronic hardware to ensure compliance with environmental standards, significantly impacting global supply chains and manufacturing costs. REACH addresses the registration and authorization of chemical substances, influencing material selection and compliance processes for hardware producers worldwide. Together, RoHS and REACH regulations drive sustainable innovation, reduce environmental risks, and shape market access strategies across international hardware markets.

Future Trends in RoHS and REACH Regulations

Future trends in RoHS and REACH regulations emphasize stricter limits on hazardous substances and expanded scope to include emerging materials such as nanomaterials and rare earth elements. Enhanced compliance requirements are expected with increased digital tracking and reporting mechanisms, leveraging blockchain technology to ensure transparency throughout the supply chain. Manufacturers in the hardware sector must proactively adopt sustainable material sourcing and advanced recycling processes to meet evolving environmental standards and avoid regulatory penalties.

RoHS vs REACH Infographic

productdif.com

productdif.com