Pin headers are male connectors with exposed pins designed to fit into socket headers, which are female connectors featuring receptacles for secure electrical connections. Socket headers provide a reliable interface for connecting wires or components without soldering, enhancing modularity and ease of assembly in hardware projects. Selecting between pin headers and socket headers depends on the required durability, ease of maintenance, and specific application configuration.

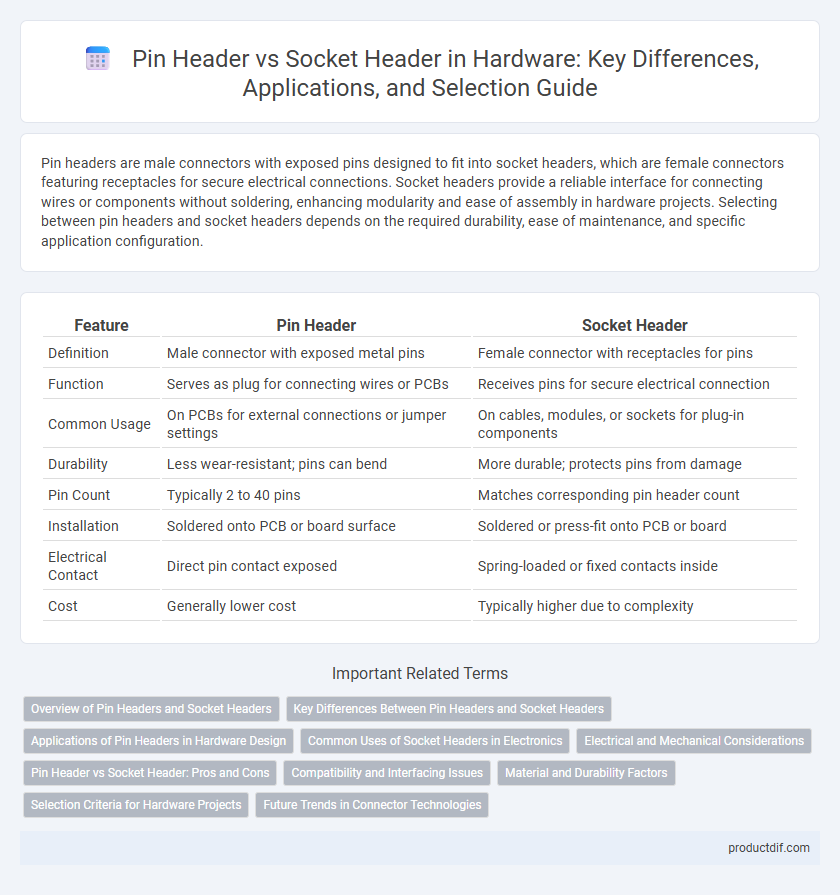

Table of Comparison

| Feature | Pin Header | Socket Header |

|---|---|---|

| Definition | Male connector with exposed metal pins | Female connector with receptacles for pins |

| Function | Serves as plug for connecting wires or PCBs | Receives pins for secure electrical connection |

| Common Usage | On PCBs for external connections or jumper settings | On cables, modules, or sockets for plug-in components |

| Durability | Less wear-resistant; pins can bend | More durable; protects pins from damage |

| Pin Count | Typically 2 to 40 pins | Matches corresponding pin header count |

| Installation | Soldered onto PCB or board surface | Soldered or press-fit onto PCB or board |

| Electrical Contact | Direct pin contact exposed | Spring-loaded or fixed contacts inside |

| Cost | Generally lower cost | Typically higher due to complexity |

Overview of Pin Headers and Socket Headers

Pin headers consist of a row or grid of metal pins that protrude from a plastic base, designed for insertion into corresponding socket headers or soldering onto printed circuit boards (PCBs). Socket headers feature a series of receptacles that provide secure electrical connections by mating with pin headers, facilitating easy modular connections and disconnections in electronic assemblies. Both components are essential in hardware design for creating reliable, removable interfaces between circuit modules and components.

Key Differences Between Pin Headers and Socket Headers

Pin headers consist of exposed metal pins designed to be soldered onto circuit boards, providing a rigid male connector interface, whereas socket headers feature corresponding female receptacles that receive the pins, enabling detachable connections. Pin headers typically offer durability and solid electrical contact but lack the flexibility of easy replacement, while socket headers allow for modularity and easier maintenance with a slight compromise on mechanical strength. The choice between pin and socket headers impacts assembly methods, connection reliability, and repairability in electronic hardware design.

Applications of Pin Headers in Hardware Design

Pin headers are widely used in hardware design for connecting printed circuit boards (PCBs) to other components or devices, facilitating easy modular assembly and repair. They enable flexible interfacing in microcontroller development boards, sensor modules, and prototyping kits by providing reliable, removable connections. Pin headers are essential in applications requiring frequent disconnection and reconnection, such as development environments, test equipment, and customizable embedded systems.

Common Uses of Socket Headers in Electronics

Socket headers are commonly used in electronics for connecting removable components such as integrated circuits (ICs), sensors, and modules, allowing easy replacement and upgrading. They facilitate reliable electrical connections in prototyping, testing, and modular system designs, especially on printed circuit boards (PCBs). Socket headers also simplify maintenance and troubleshooting by enabling quick disassembly without soldering.

Electrical and Mechanical Considerations

Pin headers offer robust electrical contact with minimal resistance due to their solid metal pins, ensuring reliable signal transmission in hardware connections. Socket headers provide mechanical flexibility by accommodating varying pin sizes and enabling easy component insertion or removal, which reduces wear on soldered connections. Electrical performance depends on contact integrity and corrosion resistance, while mechanical considerations focus on alignment precision and durability under repeated mating cycles.

Pin Header vs Socket Header: Pros and Cons

Pin headers offer a robust and cost-effective solution for connecting PCBs with reliable electrical contact, ideal for permanent or semi-permanent installations, but may require careful alignment to avoid bending pins. Socket headers provide easy insertion and removal, reducing wear on components and enabling modular designs, though they can be more vulnerable to mechanical stress and generally come at a higher cost. Choosing between pin headers and socket headers depends on factors such as durability, maintenance frequency, space constraints, and budget in electronic hardware assembly.

Compatibility and Interfacing Issues

Pin headers and socket headers are essential components for board-to-board or board-to-device connections, with pin headers featuring protruding pins that insert into corresponding sockets on the socket header. Compatibility challenges arise when pin and socket headers differ in pitch size, pin count, or alignment, causing poor contact or mechanical stress. Proper interfacing requires matching header types, pitch standards (commonly 2.54mm), and ensuring secure connections to avoid signal loss or intermittent connectivity issues.

Material and Durability Factors

Pin headers typically feature brass or phosphor bronze pins with a tin or gold plating, providing excellent conductivity and corrosion resistance, while socket headers usually incorporate a high-temperature plastic housing with phosphor bronze contacts for enhanced durability. The choice of materials directly impacts mechanical strength and long-term reliability, with gold-plated pins offering superior wear resistance compared to tin-plated alternatives. Durability factors include the ability to withstand repeated mating cycles and resistance to environmental factors such as moisture and oxidation.

Selection Criteria for Hardware Projects

Selecting between pin headers and socket headers for hardware projects depends primarily on factors such as electrical connectivity, mechanical stability, and ease of assembly. Pin headers offer robust soldered connections ideal for permanent setups, whereas socket headers facilitate quick component replacements and flexible configurations. Consider pin pitch, current rating, and environmental conditions to ensure optimal performance in the intended hardware application.

Future Trends in Connector Technologies

Future trends in connector technologies emphasize miniaturization, increased data transfer speeds, and enhanced durability for both pin headers and socket headers. Advancements in materials like high-performance plastics and gold-plated contacts improve signal integrity and corrosion resistance. Emerging smart connectors with embedded sensors and IoT compatibility are set to revolutionize hardware interconnectivity in electronics manufacturing.

Pin header vs Socket header Infographic

productdif.com

productdif.com