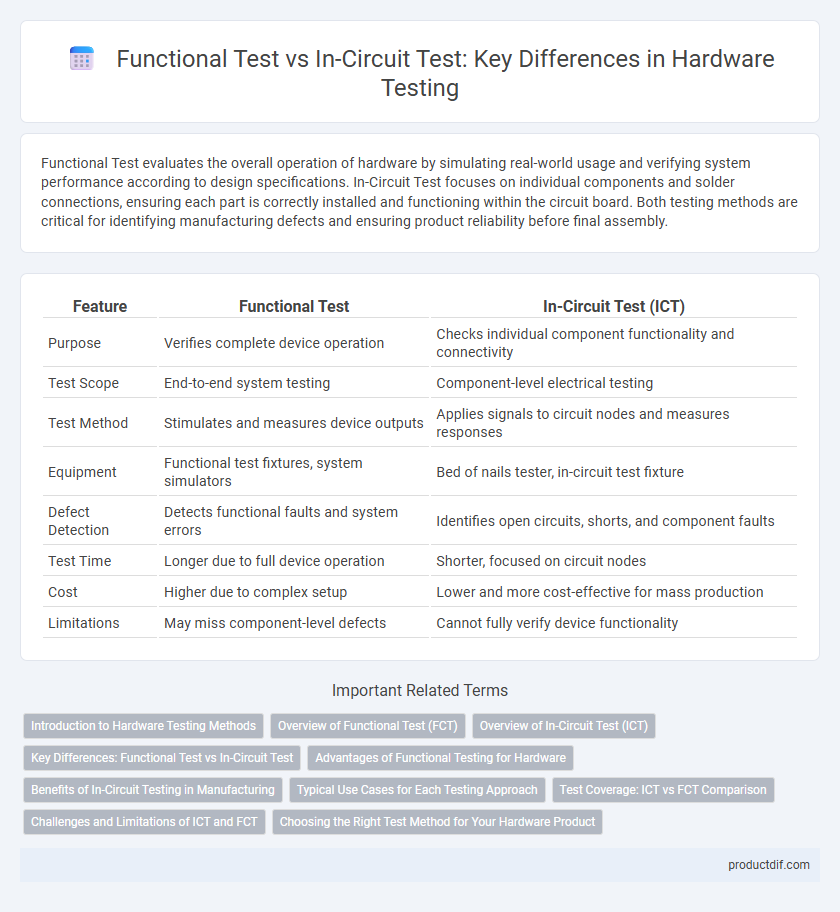

Functional Test evaluates the overall operation of hardware by simulating real-world usage and verifying system performance according to design specifications. In-Circuit Test focuses on individual components and solder connections, ensuring each part is correctly installed and functioning within the circuit board. Both testing methods are critical for identifying manufacturing defects and ensuring product reliability before final assembly.

Table of Comparison

| Feature | Functional Test | In-Circuit Test (ICT) |

|---|---|---|

| Purpose | Verifies complete device operation | Checks individual component functionality and connectivity |

| Test Scope | End-to-end system testing | Component-level electrical testing |

| Test Method | Stimulates and measures device outputs | Applies signals to circuit nodes and measures responses |

| Equipment | Functional test fixtures, system simulators | Bed of nails tester, in-circuit test fixture |

| Defect Detection | Detects functional faults and system errors | Identifies open circuits, shorts, and component faults |

| Test Time | Longer due to full device operation | Shorter, focused on circuit nodes |

| Cost | Higher due to complex setup | Lower and more cost-effective for mass production |

| Limitations | May miss component-level defects | Cannot fully verify device functionality |

Introduction to Hardware Testing Methods

Functional Test (FCT) evaluates the complete hardware system by simulating real-world operating conditions to verify overall functionality and performance, making it crucial for end-product validation. In-Circuit Test (ICT) targets individual components and solder connections on a populated PCB, using electrical probes to identify manufacturing defects such as shorts, opens, and component failures early in the assembly process. Both testing methods complement each other, ensuring hardware reliability by addressing different stages of the production and verification lifecycle.

Overview of Functional Test (FCT)

Functional Test (FCT) evaluates a fully assembled hardware device by simulating real-world operating conditions to verify end-to-end functionality and performance. It measures the complete system behavior, including software and hardware integration, ensuring the product meets specified design requirements and operational standards. FCT is essential for detecting functional defects that might not be identified by component-level tests like In-Circuit Test (ICT).

Overview of In-Circuit Test (ICT)

In-Circuit Test (ICT) is a hardware testing method designed to verify the integrity of individual components and connections on a printed circuit board (PCB) by applying electrical probes directly to test points. ICT identifies faults such as shorts, opens, resistance, capacitance, and component values to ensure correct placement and functionality before assembly completion. This test significantly reduces downstream defects by detecting manufacturing errors early in the production process.

Key Differences: Functional Test vs In-Circuit Test

Functional Test evaluates the complete hardware system's performance by simulating real-world operating conditions to verify overall functionality, while In-Circuit Test (ICT) inspects individual electronic components and solder joints on a PCB to detect manufacturing defects. Functional Test addresses software-hardware interaction and system-level verification, whereas In-Circuit Test uses bed-of-nails fixtures to provide rapid pinpoint diagnostics during production. Key differences include Functional Test's holistic scope versus ICT's focus on component-level integrity and fault isolation.

Advantages of Functional Testing for Hardware

Functional testing offers significant advantages for hardware validation by verifying the complete system operation, ensuring that all integrated components work together as intended under real-world conditions. Unlike in-circuit testing, which focuses on individual component-level faults, functional testing identifies issues related to overall device performance, software interactions, and interface functionality. This holistic approach reduces the risk of undetected system-level failures and improves product reliability and customer satisfaction.

Benefits of In-Circuit Testing in Manufacturing

In-circuit testing (ICT) offers precise fault detection by directly accessing individual components on a PCB, enabling early identification of manufacturing defects such as solder bridges, open circuits, and incorrect component placements. Unlike functional testing, ICT provides rapid diagnosis and reduces testing time by automating the evaluation process, improving production throughput and yield rates. The enhanced accuracy and coverage of ICT significantly lower costs associated with rework and field failures, optimizing overall manufacturing quality control.

Typical Use Cases for Each Testing Approach

Functional Test is typically used for verifying the overall operation of a fully assembled printed circuit board (PCB) by simulating real-world operating conditions, ensuring that all integrated components and subsystems work together as designed. In-Circuit Test (ICT) is primarily employed for detecting manufacturing defects at the component level, such as shorts, opens, and incorrect components, by electrically probing individual nodes on the PCB before final assembly. Functional Test is ideal for end-of-line testing in complex products, while ICT is favored in early-stage production for quick fault isolation and quality control.

Test Coverage: ICT vs FCT Comparison

In-Circuit Test (ICT) offers comprehensive coverage by directly probing individual components and solder joints on the PCB, detecting shorts, opens, and component failures with high accuracy. Functional Test (FCT) evaluates the entire assembled system's performance, ensuring the device operates correctly under real-world conditions but may miss low-level hardware defects identifiable by ICT. Combining ICT's detailed hardware verification with FCT's system-level validation maximizes overall test coverage, reducing the risk of undetected faults in production.

Challenges and Limitations of ICT and FCT

In-Circuit Test (ICT) faces challenges such as limited accessibility to densely packed components and difficulty testing complex analog circuits, which restricts comprehensive fault detection. Functional Test (FCT) overcomes some ICT limitations by evaluating the entire system operation but struggles with longer test times and the need for fully assembled products. Both ICT and FCT require careful test program development to address limitations like false failures and incomplete coverage, impacting overall test efficiency.

Choosing the Right Test Method for Your Hardware Product

Choosing the right test method for your hardware product depends on factors like defect coverage, cost, and test time. Functional tests validate the overall operation by simulating real-world conditions, while in-circuit tests assess individual components and solder joints for manufacturing defects. Optimal hardware testing strategies often combine both methods to ensure comprehensive quality assurance and minimize production failures.

Functional Test vs In-Circuit Test Infographic

productdif.com

productdif.com