Lead-acid batteries offer a cost-effective power solution with reliable performance for stationary and automotive applications, but they have lower energy density and shorter lifespan compared to lithium-ion batteries. Lithium-ion technology provides higher energy density, faster charging times, and longer cycle life, making it ideal for portable electronics and electric vehicles despite a higher upfront cost. The choice between lead-acid and lithium-ion depends on specific requirements such as budget, weight constraints, and expected usage duration.

Table of Comparison

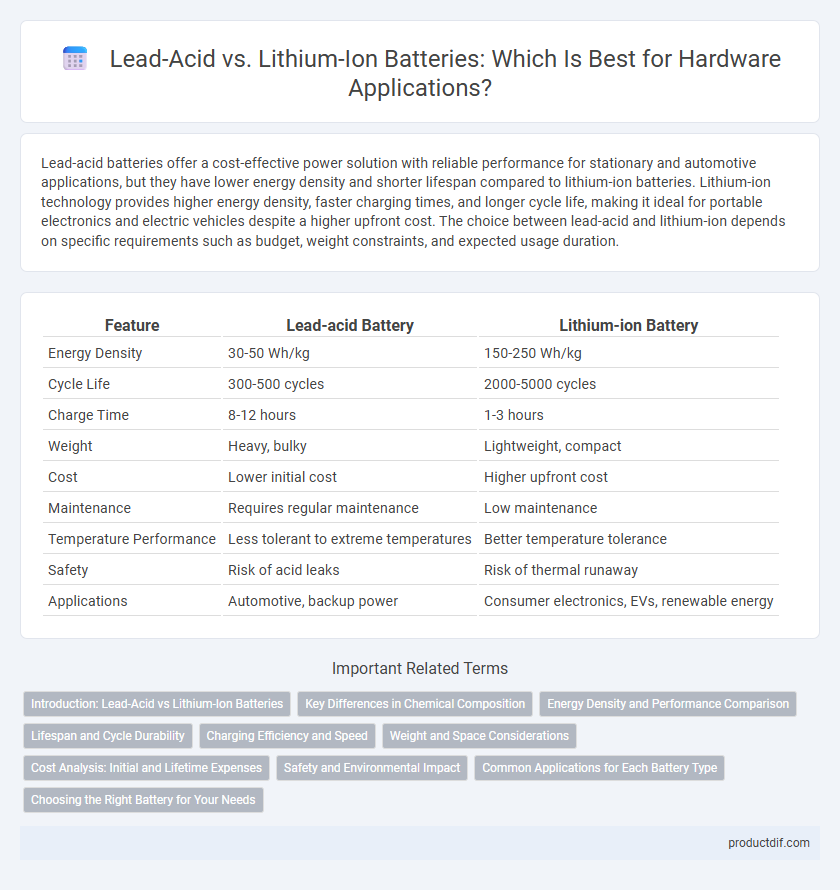

| Feature | Lead-acid Battery | Lithium-ion Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 300-500 cycles | 2000-5000 cycles |

| Charge Time | 8-12 hours | 1-3 hours |

| Weight | Heavy, bulky | Lightweight, compact |

| Cost | Lower initial cost | Higher upfront cost |

| Maintenance | Requires regular maintenance | Low maintenance |

| Temperature Performance | Less tolerant to extreme temperatures | Better temperature tolerance |

| Safety | Risk of acid leaks | Risk of thermal runaway |

| Applications | Automotive, backup power | Consumer electronics, EVs, renewable energy |

Introduction: Lead-Acid vs Lithium-Ion Batteries

Lead-acid batteries, known for their reliability and cost-effectiveness, have been a staple in automotive and backup power applications for decades. Lithium-ion batteries offer higher energy density, longer lifespan, and faster recharge times, making them ideal for portable electronics and electric vehicles. The choice between lead-acid and lithium-ion depends on specific requirements like weight, efficiency, and budget constraints.

Key Differences in Chemical Composition

Lead-acid batteries utilize lead dioxide and sponge lead as electrodes with sulfuric acid as the electrolyte, creating a heavy and corrosive chemical composition. Lithium-ion batteries feature lithium cobalt oxide or lithium iron phosphate cathodes paired with graphite anodes, using organic solvents as electrolytes that enable higher energy density and longer cycle life. The fundamental chemical differences result in varied performance characteristics, weight, and maintenance requirements for each battery type.

Energy Density and Performance Comparison

Lithium-ion batteries offer significantly higher energy density, typically ranging from 150 to 250 Wh/kg, compared to lead-acid batteries, which generally range from 30 to 50 Wh/kg, enabling longer runtime and reduced weight in hardware applications. Performance-wise, lithium-ion cells exhibit superior charge/discharge efficiency, faster charging times, and longer cycle life, often exceeding 2,000 cycles, whereas lead-acid batteries typically provide around 500 to 1,000 cycles with slower charge rates. This energy density and performance advantage makes lithium-ion the preferred choice for modern electronic devices and electric vehicles demanding high power and extended battery life.

Lifespan and Cycle Durability

Lead-acid batteries typically offer a lifespan of 3 to 5 years and support around 300 to 500 charge cycles before significant capacity loss, making them suitable for applications with low cycle demands. Lithium-ion batteries provide a longer lifespan of 8 to 15 years and can endure 1,000 to 5,000 charge cycles, depending on the specific chemistry and usage conditions, enhancing their cycle durability. This superior cycle performance and extended lifespan make lithium-ion batteries the preferred choice for high-demand hardware requiring consistent and long-term energy storage.

Charging Efficiency and Speed

Lithium-ion batteries exhibit superior charging efficiency, converting over 90% of energy into usable power compared to lead-acid batteries, which typically achieve around 70-80%. Charging speed for lithium-ion cells is significantly faster, often reaching full capacity within 1 to 3 hours, whereas lead-acid batteries usually require 8 to 12 hours for a full charge. This efficiency and speed advantage reduces downtime and enhances overall performance in hardware applications.

Weight and Space Considerations

Lithium-ion batteries weigh up to 70% less than lead-acid batteries, offering significant advantages in weight-sensitive applications such as electric vehicles and portable hardware. They also have a higher energy density, typically around 150-200 Wh/kg compared to lead-acid's 30-50 Wh/kg, enabling more compact designs and efficient use of space. Reduced size and mass in lithium-ion cells lead to improved hardware performance, extended runtime, and enhanced portability.

Cost Analysis: Initial and Lifetime Expenses

Lead-acid batteries typically have lower initial costs compared to lithium-ion batteries, making them attractive for budget-conscious applications; however, their shorter lifespan and higher maintenance expenses increase overall lifetime costs. Lithium-ion batteries, despite higher upfront investment, offer longer cycle life and reduced maintenance, resulting in lower total cost of ownership over time. Analyzing cost per cycle and energy density reveals lithium-ion as more cost-efficient for long-term use despite a higher initial price tag.

Safety and Environmental Impact

Lead-acid batteries pose higher risks of acid leaks and hydrogen gas explosions, requiring careful handling and ventilation to ensure safety. Lithium-ion batteries feature improved safety mechanisms such as built-in thermal management systems, reducing the likelihood of overheating and fires. Environmentally, lead-acid batteries contain toxic lead and sulfuric acid that demand proper recycling to prevent soil and water contamination, whereas lithium-ion batteries offer longer lifespans and lower metal toxicity but require complex recycling processes to recover valuable metals like cobalt and lithium.

Common Applications for Each Battery Type

Lead-acid batteries are commonly used in automotive starters, uninterruptible power supplies (UPS), and backup power for emergency lighting due to their cost-effectiveness and reliability. Lithium-ion batteries dominate portable electronics, electric vehicles, and renewable energy storage systems because of their high energy density and longer cycle life. Each battery type's unique chemistry and performance characteristics determine its suitability for specific hardware applications across various industries.

Choosing the Right Battery for Your Needs

Lead-acid batteries offer a cost-effective solution with reliable performance for applications requiring steady power and deep discharge capabilities. Lithium-ion batteries excel in energy density, longer lifespan, and faster charging, making them ideal for portable electronics, electric vehicles, and renewable energy storage. Selecting the right battery depends on factors such as budget, weight constraints, energy demands, cycle life, and maintenance requirements to optimize efficiency and longevity.

Lead-acid vs Lithium-ion Infographic

productdif.com

productdif.com