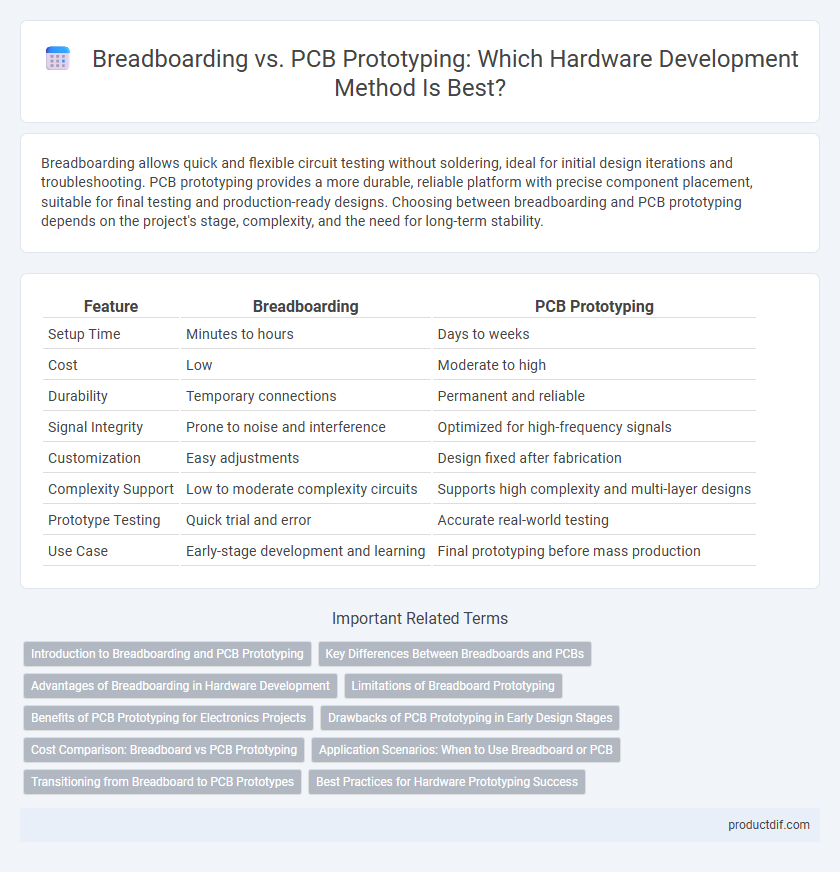

Breadboarding allows quick and flexible circuit testing without soldering, ideal for initial design iterations and troubleshooting. PCB prototyping provides a more durable, reliable platform with precise component placement, suitable for final testing and production-ready designs. Choosing between breadboarding and PCB prototyping depends on the project's stage, complexity, and the need for long-term stability.

Table of Comparison

| Feature | Breadboarding | PCB Prototyping |

|---|---|---|

| Setup Time | Minutes to hours | Days to weeks |

| Cost | Low | Moderate to high |

| Durability | Temporary connections | Permanent and reliable |

| Signal Integrity | Prone to noise and interference | Optimized for high-frequency signals |

| Customization | Easy adjustments | Design fixed after fabrication |

| Complexity Support | Low to moderate complexity circuits | Supports high complexity and multi-layer designs |

| Prototype Testing | Quick trial and error | Accurate real-world testing |

| Use Case | Early-stage development and learning | Final prototyping before mass production |

Introduction to Breadboarding and PCB Prototyping

Breadboarding enables rapid circuit assembly using reusable, solderless boards with interconnected sockets, ideal for testing and debugging electronic components without permanent connections. PCB prototyping involves designing and fabricating printed circuit boards that provide durable, precise layouts for complex circuits, enhancing electrical performance and reliability. Breadboarding suits early-stage development, while PCB prototyping supports advanced iterations and final product preparation.

Key Differences Between Breadboards and PCBs

Breadboards offer quick and flexible prototyping with reusable components and no soldering, ideal for testing and circuit modifications. Printed Circuit Boards (PCBs) provide permanent, reliable connections with custom layouts, better electrical performance, and durability for final hardware designs. Key differences include assembly methods, signal integrity, mechanical stability, and suitability for high-frequency or production-ready applications.

Advantages of Breadboarding in Hardware Development

Breadboarding offers rapid experimentation and easy modifications without soldering, which accelerates hardware development cycles and reduces initial costs. It enables immediate troubleshooting and component swaps, making it ideal for testing circuit designs and validating concepts before committing to a printed circuit board (PCB). The flexibility of breadboards supports iterative design and educational purposes, allowing engineers to quickly prototype and refine hardware projects.

Limitations of Breadboard Prototyping

Breadboard prototyping faces limitations such as unreliable connections due to loose jumper wires and contact resistance, which can lead to intermittent faults and signal integrity issues. The layout constraints restrict high-frequency circuit testing because of parasitic capacitance and inductance inherent in breadboard terminals. Additionally, breadboards lack durability for long-term use and are unsuitable for complex circuits requiring precise component placement and thermal management.

Benefits of PCB Prototyping for Electronics Projects

PCB prototyping offers superior reliability and durability compared to breadboarding, ensuring stable electrical connections and reduced signal interference for complex electronics projects. It allows precise component placement and trace routing, which improves circuit performance and facilitates easier replication for mass production. Additionally, PCB prototypes support compact designs and professional aesthetics, essential for device integration and functionality testing.

Drawbacks of PCB Prototyping in Early Design Stages

PCB prototyping in early design stages often leads to increased costs due to fabrication and assembly expenses before finalizing the circuit. The long turnaround time for PCB manufacturing can delay iterative testing and design modifications compared to breadboarding. Additionally, the inflexibility of PCBs makes quick adjustments challenging, hindering rapid prototyping and troubleshooting.

Cost Comparison: Breadboard vs PCB Prototyping

Breadboarding offers a low-cost, flexible solution ideal for initial prototyping and circuit testing without the need for manufacturing expenses. PCB prototyping, although more expensive upfront due to design, manufacturing, and assembly costs, provides enhanced durability, reliability, and suitability for complex or long-term projects. Evaluating total cost must consider factors like production volume, time-to-market, and required circuit stability, with breadboards favored for quick, low-budget experimentation and PCBs preferred for scalable, professional applications.

Application Scenarios: When to Use Breadboard or PCB

Breadboarding is ideal for rapid prototyping and testing low-frequency or simple electronic circuits where quick modifications are needed without soldering. PCB prototyping suits high-frequency, durable, and complex designs requiring reliable connections and compact layouts for final product validation. Engineers often choose breadboards for educational purposes and initial development, switching to PCBs when finalized circuits need robustness and mass production feasibility.

Transitioning from Breadboard to PCB Prototypes

Transitioning from breadboarding to PCB prototypes significantly enhances circuit reliability and performance by providing stable, soldered connections that minimize signal interference and mechanical failures. PCB prototyping allows for precise component placement and optimized trace routing, essential for complex or high-frequency designs where breadboards fall short. This shift facilitates easier debugging, scalability, and prepares the design for mass production with standardized manufacturing processes.

Best Practices for Hardware Prototyping Success

Breadboarding offers flexibility for rapid circuit testing and modification, ideal for initial design validation and troubleshooting hardware functionality. PCB prototyping delivers higher reliability, durability, and accurate real-world performance by providing fixed component placement and professional signal integrity. Combining iterative breadboard testing with precise PCB prototyping accelerates development cycles and ensures robust hardware design success.

Breadboarding vs PCB Prototyping Infographic

productdif.com

productdif.com