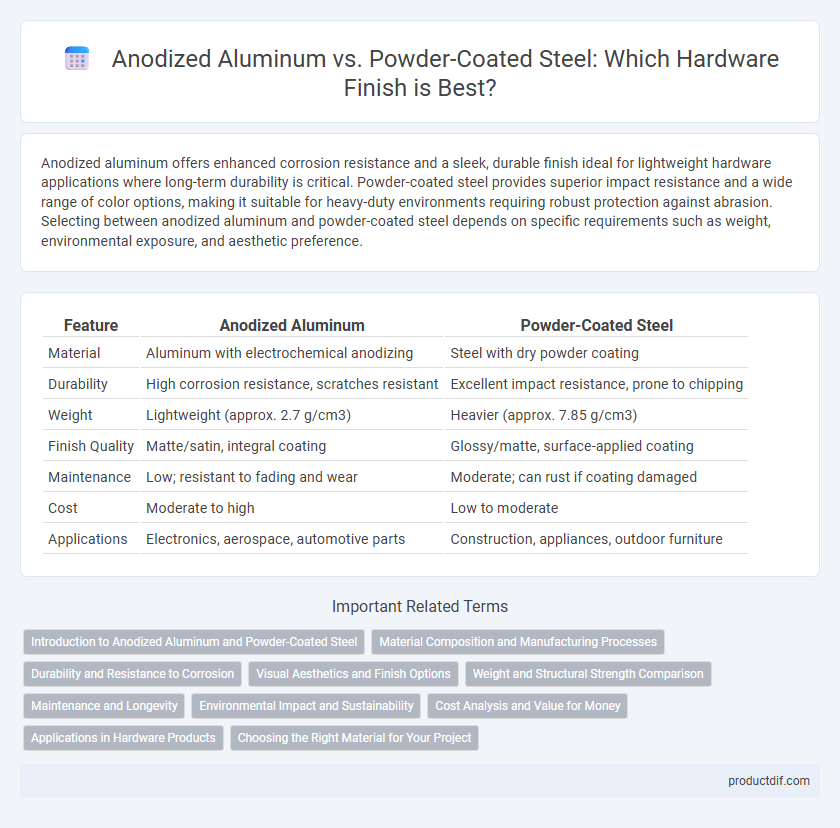

Anodized aluminum offers enhanced corrosion resistance and a sleek, durable finish ideal for lightweight hardware applications where long-term durability is critical. Powder-coated steel provides superior impact resistance and a wide range of color options, making it suitable for heavy-duty environments requiring robust protection against abrasion. Selecting between anodized aluminum and powder-coated steel depends on specific requirements such as weight, environmental exposure, and aesthetic preference.

Table of Comparison

| Feature | Anodized Aluminum | Powder-Coated Steel |

|---|---|---|

| Material | Aluminum with electrochemical anodizing | Steel with dry powder coating |

| Durability | High corrosion resistance, scratches resistant | Excellent impact resistance, prone to chipping |

| Weight | Lightweight (approx. 2.7 g/cm3) | Heavier (approx. 7.85 g/cm3) |

| Finish Quality | Matte/satin, integral coating | Glossy/matte, surface-applied coating |

| Maintenance | Low; resistant to fading and wear | Moderate; can rust if coating damaged |

| Cost | Moderate to high | Low to moderate |

| Applications | Electronics, aerospace, automotive parts | Construction, appliances, outdoor furniture |

Introduction to Anodized Aluminum and Powder-Coated Steel

Anodized aluminum is created by electrochemically oxidizing the metal's surface, forming a durable, corrosion-resistant layer that enhances both strength and aesthetics. Powder-coated steel involves applying a dry powder paint that is then cured under heat to produce a tough, protective finish resistant to chipping, scratching, and corrosion. Both materials are widely used in hardware applications for their protective qualities and visual appeal, with anodized aluminum offering lightweight benefits and powder-coated steel providing superior impact resistance.

Material Composition and Manufacturing Processes

Anodized aluminum undergoes an electrochemical process that enhances its natural oxide layer, improving corrosion resistance and surface hardness without adding a thick coating. Powder-coated steel involves applying a dry powder cured under heat to form a durable, protective finish that resists chipping and weathering. The lightweight nature of aluminum paired with its anodized finish contrasts with the heavier steel substrate, which gains strength and color stability through the powder coating process.

Durability and Resistance to Corrosion

Anodized aluminum offers superior corrosion resistance due to its electrochemical process that thickens the natural oxide layer, making it highly durable in harsh environments and resistant to scratching. Powder-coated steel, while providing a tough protective layer against corrosion and impact, can chip or peel over time, exposing the steel underneath to rust. Both materials are durable, but anodized aluminum excels in environments where sustained corrosion resistance is critical, such as marine or industrial applications.

Visual Aesthetics and Finish Options

Anodized aluminum offers a sleek, metallic finish that enhances natural texture with superior resistance to scratching and corrosion, making it ideal for modern hardware designs requiring durability and a premium look. Powder-coated steel provides a wide range of vibrant colors and textures with a thick, uniform coating that improves impact resistance but may chip over time under heavy use. Choosing between anodized aluminum and powder-coated steel depends on balancing the desired visual aesthetics and long-term finish durability for specific hardware applications.

Weight and Structural Strength Comparison

Anodized aluminum offers a significant weight advantage over powder-coated steel, making it ideal for applications where reducing overall mass is critical, such as aerospace and automotive components. Despite its lightness, anodized aluminum maintains strong corrosion resistance but generally exhibits lower tensile strength compared to powder-coated steel, which delivers superior structural strength and impact resistance due to its dense molecular composition and protective powder coating. Selecting between the two depends on balancing lightweight design requirements against the need for enhanced durability and load-bearing capacity in hardware projects.

Maintenance and Longevity

Anodized aluminum offers superior corrosion resistance and requires minimal maintenance due to its durable oxide layer, making it ideal for outdoor and harsh environments. Powder-coated steel provides a tough, protective finish that resists chipping and scratching but may need periodic repainting to prevent rust and maintain appearance. Longevity of anodized aluminum typically exceeds powder-coated steel in corrosive conditions, ensuring extended hardware lifespan with less upkeep.

Environmental Impact and Sustainability

Anodized aluminum offers superior corrosion resistance and is highly recyclable, reducing environmental impact through lower energy requirements in the recycling process compared to powder-coated steel. Powder-coated steel involves the use of chemical coatings and curing processes that can emit volatile organic compounds (VOCs), posing sustainability challenges. The lightweight nature of anodized aluminum also contributes to lower transportation emissions, enhancing its eco-friendly profile over powder-coated steel in hardware applications.

Cost Analysis and Value for Money

Anodized aluminum generally offers a higher upfront cost compared to powder-coated steel but provides superior corrosion resistance and long-term durability, reducing maintenance expenses. Powder-coated steel is more budget-friendly initially and offers a wide range of color options, though it may require more frequent recoating in harsh environments. Evaluating total cost of ownership, anodized aluminum delivers better value for money in applications demanding longevity and low upkeep, while powder-coated steel suits projects with tighter initial budgets.

Applications in Hardware Products

Anodized aluminum is widely used in hardware products requiring corrosion resistance and lightweight properties, such as window frames, electronic enclosures, and architectural fittings. Powder-coated steel is preferred for heavy-duty applications like industrial machinery, outdoor furniture, and automotive components due to its excellent durability and resistance to impact and weathering. Both materials offer distinct advantages in hardware manufacturing, with anodized aluminum excelling in aesthetics and corrosion protection, while powder-coated steel provides superior strength and long-term wear resistance.

Choosing the Right Material for Your Project

Anodized aluminum offers superior corrosion resistance and a lightweight profile, making it ideal for projects requiring durability and ease of handling. Powder-coated steel provides excellent impact resistance and a wide range of color options, suitable for applications demanding robust structural strength. Selecting between the two depends on factors like environmental exposure, mechanical stress, and aesthetic preferences to ensure optimal performance and longevity.

Anodized Aluminum vs Powder-Coated Steel Infographic

productdif.com

productdif.com