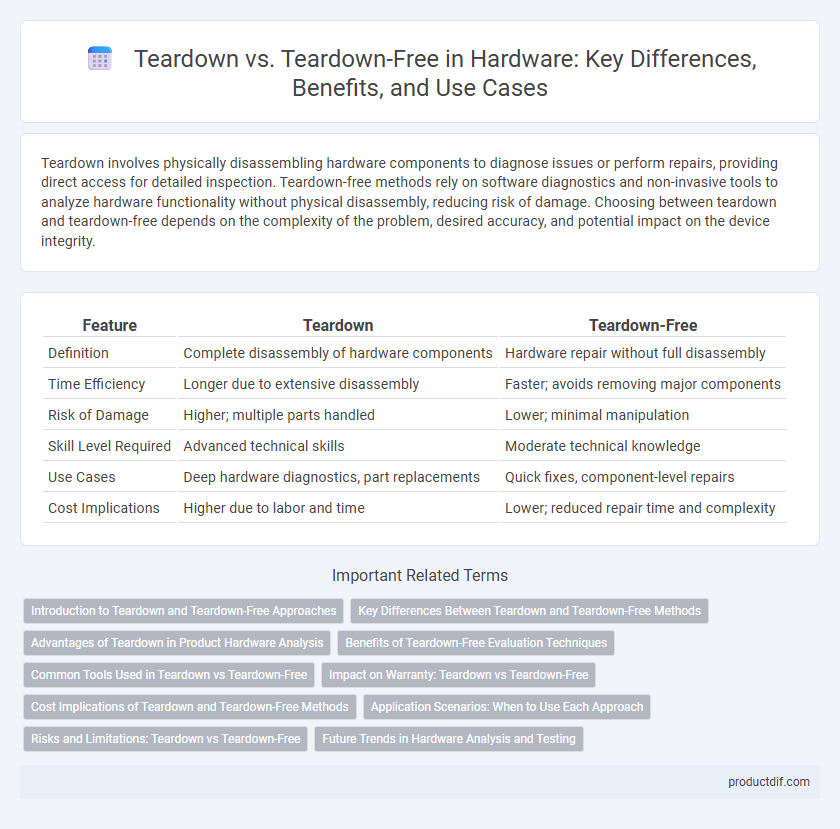

Teardown involves physically disassembling hardware components to diagnose issues or perform repairs, providing direct access for detailed inspection. Teardown-free methods rely on software diagnostics and non-invasive tools to analyze hardware functionality without physical disassembly, reducing risk of damage. Choosing between teardown and teardown-free depends on the complexity of the problem, desired accuracy, and potential impact on the device integrity.

Table of Comparison

| Feature | Teardown | Teardown-Free |

|---|---|---|

| Definition | Complete disassembly of hardware components | Hardware repair without full disassembly |

| Time Efficiency | Longer due to extensive disassembly | Faster; avoids removing major components |

| Risk of Damage | Higher; multiple parts handled | Lower; minimal manipulation |

| Skill Level Required | Advanced technical skills | Moderate technical knowledge |

| Use Cases | Deep hardware diagnostics, part replacements | Quick fixes, component-level repairs |

| Cost Implications | Higher due to labor and time | Lower; reduced repair time and complexity |

Introduction to Teardown and Teardown-Free Approaches

Teardown refers to the detailed disassembly process of hardware components to analyze design, repairability, or manufacturing techniques. Teardown-free approaches leverage non-invasive methods such as X-ray imaging, infrared scanning, and software diagnostics to inspect hardware without physical dismantling. These techniques optimize time efficiency and reduce risks of damaging sensitive components while maintaining insight into device structure.

Key Differences Between Teardown and Teardown-Free Methods

Teardown methods involve physically disassembling hardware components to inspect, repair, or analyze them, providing detailed insights into internal structures and possible faults. Teardown-free methods utilize non-invasive techniques such as imaging, software diagnostics, or thermal analysis, enabling hardware assessment without physical damage or disassembly. Key differences include the level of hardware access, potential risk of damage, and the depth of information obtained, with teardown offering comprehensive physical data and teardown-free methods prioritizing preservation and rapid evaluation.

Advantages of Teardown in Product Hardware Analysis

Teardown in product hardware analysis enables detailed inspection of internal components, revealing design quality and manufacturing processes critical for assessing performance and durability. This method provides precise identification of proprietary technologies and potential vulnerabilities that teardown-free techniques often miss. Accessing physical layers directly accelerates innovation by informing reverse engineering, cost estimation, and competitive benchmarking.

Benefits of Teardown-Free Evaluation Techniques

Teardown-free evaluation techniques enable accurate hardware performance analysis without physically disassembling components, preserving device integrity and reducing the risk of damage. These methods provide faster diagnostics, allowing for real-time monitoring and maintenance while minimizing downtime. They also facilitate cost savings by eliminating the need for specialized disassembly tools and labor-intensive processes.

Common Tools Used in Teardown vs Teardown-Free

Common tools used in hardware teardown include precision screwdrivers, spudgers, and tweezers, which facilitate the disassembly of devices to access internal components. In contrast, teardown-free approaches rely on non-invasive techniques such as diagnostic software, thermal cameras, and X-ray imaging to analyze hardware without physical disassembly. The choice between teardown and teardown-free methods impacts repairability, data recovery, and the ability to conduct detailed component-level inspections.

Impact on Warranty: Teardown vs Teardown-Free

Teardown procedures often void the manufacturer's warranty due to the risk of damage during disassembly, while teardown-free designs maintain warranty coverage by allowing repair or diagnosis without opening the device. Warranty impact is a critical factor for consumers choosing between hardware that requires physical teardown and those engineered for non-invasive servicing. Teardown-free solutions reduce costs associated with warranty claims and enhance user confidence in product longevity.

Cost Implications of Teardown and Teardown-Free Methods

Teardown methods in hardware repair typically involve disassembling devices, which increases labor costs and risk of component damage, leading to higher overall expenses. Teardown-free approaches reduce the need for physical disassembly by using diagnostic tools and modular designs, lowering service time and operational costs. Choosing teardown-free techniques enhances cost efficiency by minimizing repair turnaround and preserving device integrity.

Application Scenarios: When to Use Each Approach

Teardown is ideal for hardware repair and detailed diagnostics in complex devices where component-level inspection or replacement is necessary. Teardown-Free approaches suit rapid troubleshooting and user-level maintenance, leveraging built-in diagnostics and modular designs to minimize device disassembly. Choosing between the two depends on factors like device complexity, required repair precision, and time constraints in repair workflows.

Risks and Limitations: Teardown vs Teardown-Free

Teardown hardware procedures involve physical disassembly that risks damage to sensitive components and voids manufacturer warranties, limiting device reuse and repairability. Teardown-free techniques employ non-invasive diagnostic tools like X-rays or software-based analysis, reducing physical risk but often providing less detailed insights into internal hardware faults. Both approaches face limitations in accuracy and accessibility, with teardown offering comprehensive inspection at the cost of potential hardware damage, while teardown-free methods prioritize safety but may miss critical internal defects.

Future Trends in Hardware Analysis and Testing

Future trends in hardware analysis emphasize the shift from traditional teardown methods to teardown-free techniques, leveraging advanced imaging technologies and AI-powered diagnostics to analyze components without physical disassembly. This approach enhances accuracy, reduces testing time, and minimizes risk of damage, crucial for increasingly miniaturized and complex devices. Integration of real-time monitoring and non-invasive sensors is expected to drive the evolution of hardware testing, enabling continuous performance assessment and predictive maintenance.

Teardown vs Teardown-Free Infographic

productdif.com

productdif.com