Rigid Flex PCBs combine the advantages of both rigid and flexible circuits, offering enhanced durability and space-saving design compared to standard PCBs. These hybrid boards provide superior reliability in complex electronic devices by reducing interconnection failures and improving signal integrity. Standard PCBs, while cost-effective and easier to manufacture, lack the flexibility and compactness needed for modern miniaturized applications.

Table of Comparison

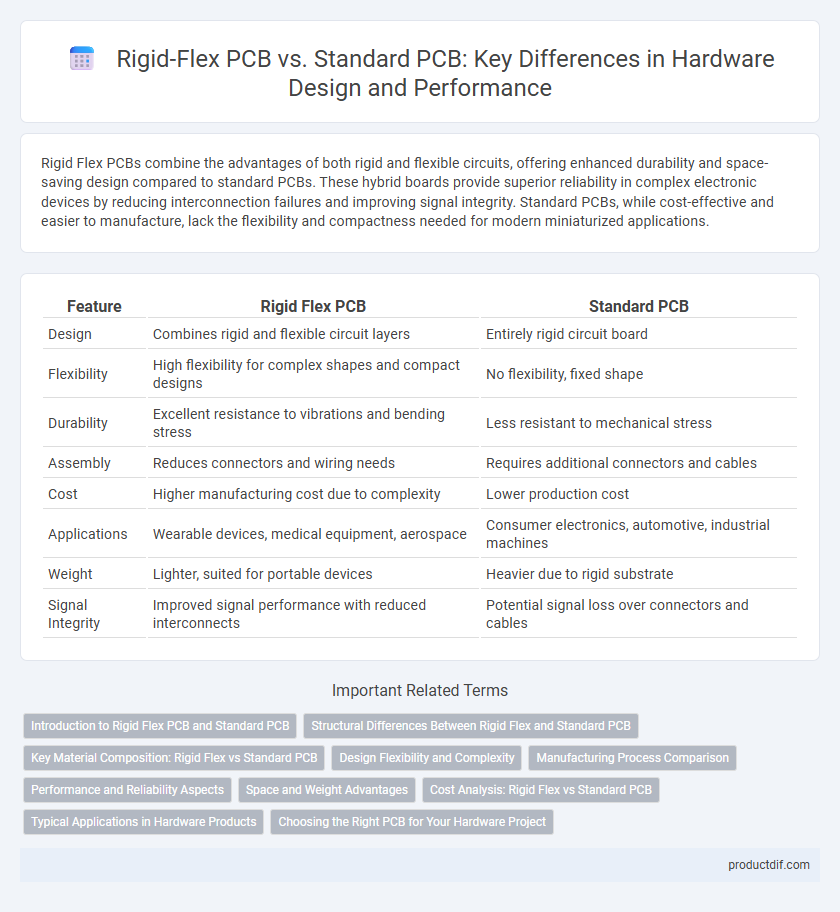

| Feature | Rigid Flex PCB | Standard PCB |

|---|---|---|

| Design | Combines rigid and flexible circuit layers | Entirely rigid circuit board |

| Flexibility | High flexibility for complex shapes and compact designs | No flexibility, fixed shape |

| Durability | Excellent resistance to vibrations and bending stress | Less resistant to mechanical stress |

| Assembly | Reduces connectors and wiring needs | Requires additional connectors and cables |

| Cost | Higher manufacturing cost due to complexity | Lower production cost |

| Applications | Wearable devices, medical equipment, aerospace | Consumer electronics, automotive, industrial machines |

| Weight | Lighter, suited for portable devices | Heavier due to rigid substrate |

| Signal Integrity | Improved signal performance with reduced interconnects | Potential signal loss over connectors and cables |

Introduction to Rigid Flex PCB and Standard PCB

Rigid Flex PCB combines the advantages of both rigid and flexible circuit boards to enhance design versatility and reduce assembly complexity. Standard PCB consists of a single, rigid substrate, typically made from FR-4, providing a stable foundation for electronic components but limited flexibility. Rigid Flex PCBs are increasingly favored in compact devices, aerospace, and medical applications due to their ability to withstand dynamic bending and minimize space.

Structural Differences Between Rigid Flex and Standard PCB

Rigid flex PCBs combine flexible and rigid substrates, allowing for intricate three-dimensional configurations and reducing the need for connectors, which enhances durability and space efficiency. Standard PCBs are composed solely of rigid materials, typically FR4, providing a flat and stable platform but lacking flexibility and compact design options. The structural integration in rigid flex PCBs facilitates better mechanical reliability in dynamic environments compared to the fixed structure of standard PCBs.

Key Material Composition: Rigid Flex vs Standard PCB

Rigid Flex PCBs combine flexible polyimide substrates with traditional FR4 rigid materials, enabling complex 3D designs and enhanced durability. Standard PCBs primarily consist of FR4 epoxy resin, providing rigidity but lacking the flexibility found in Rigid Flex configurations. The hybrid material composition of Rigid Flex PCBs allows for weight reduction and improved resistance to vibration and mechanical stress compared to conventional FR4-only boards.

Design Flexibility and Complexity

Rigid Flex PCB offers superior design flexibility by combining rigid and flexible circuits in a single assembly, enabling complex, three-dimensional configurations that standard PCBs cannot achieve. This integration reduces the need for connectors and cables, which improves reliability and saves space in compact electronic devices. Standard PCBs, while easier to design and manufacture, are limited to flat, two-dimensional layouts, reducing their adaptability in advanced applications requiring dynamic or curved shapes.

Manufacturing Process Comparison

Rigid Flex PCBs integrate rigid and flexible substrates, requiring advanced manufacturing techniques such as multi-layer lamination and precise laser cutting, increasing complexity compared to standard PCB fabrication. Standard PCBs follow conventional processes involving etching, drilling, and solder mask application on a single or multi-layer rigid board, typically resulting in faster and more cost-effective production. The manufacturing process of Rigid Flex PCBs demands stricter quality control and more intricate material handling to ensure reliability across flex zones and rigid sections.

Performance and Reliability Aspects

Rigid flex PCBs offer superior performance through enhanced mechanical flexibility, allowing for complex 3D configurations and reducing the need for connectors, which improves signal integrity. These PCBs exhibit higher reliability under dynamic stress and vibrations, making them ideal for demanding applications such as aerospace and medical devices. Standard PCBs, while cost-effective and easier to manufacture, are more prone to failure in flexible or high-stress environments due to their rigid structure and limited durability.

Space and Weight Advantages

Rigid flex PCBs combine flexible and rigid circuit layers, significantly reducing overall space requirements in electronic devices by enabling complex 3D configurations. Their lightweight construction minimizes the need for heavy connectors and cables, leading to a lower total device weight compared to standard PCBs. This optimized design enhances compactness and durability, making rigid flex PCBs ideal for aerospace, medical, and wearable technology applications.

Cost Analysis: Rigid Flex vs Standard PCB

Rigid Flex PCBs typically involve higher upfront manufacturing costs due to their complex design and multi-layer construction, but they can reduce overall system expenses by minimizing assembly time and improving reliability. Standard PCBs generally offer lower initial costs and simpler fabrication processes but may lead to increased expenses from additional connectors, interconnects, and mechanical failures in complex applications. Evaluating total cost of ownership reveals Rigid Flex PCBs as cost-effective solutions in high-density, compact electronics by reducing long-term maintenance and enhancing performance.

Typical Applications in Hardware Products

Rigid flex PCBs are commonly used in advanced hardware products such as medical devices, aerospace equipment, and wearable technology where space constraints and high reliability are critical. Standard PCBs are preferred in consumer electronics, automotive control systems, and industrial machinery due to their cost-effectiveness and ease of production. The combination of rigid and flexible layers in rigid flex PCBs allows for durable, compact designs ideal for complex, high-performance applications.

Choosing the Right PCB for Your Hardware Project

Rigid Flex PCBs combine the durability of rigid boards with the flexibility of flexible circuits, making them ideal for compact, multi-dimensional hardware designs requiring high reliability and space savings. Standard PCBs are cost-effective and easier to manufacture, suitable for simpler, flatter electronic assemblies without complex bending or folding needs. Selecting between Rigid Flex and Standard PCBs depends on project-specific factors such as mechanical stress, space constraints, and signal integrity requirements.

Rigid Flex PCB vs Standard PCB Infographic

productdif.com

productdif.com