Hardware pet prototypes offer a crucial stage for testing design functionality, usability, and durability before committing to full-scale production. Production models benefit from refined components, optimized manufacturing processes, and rigorous quality control to ensure consistent performance and reliability. Choosing between prototype and production hardware pets depends on the need for iterative development versus market-ready functionality.

Table of Comparison

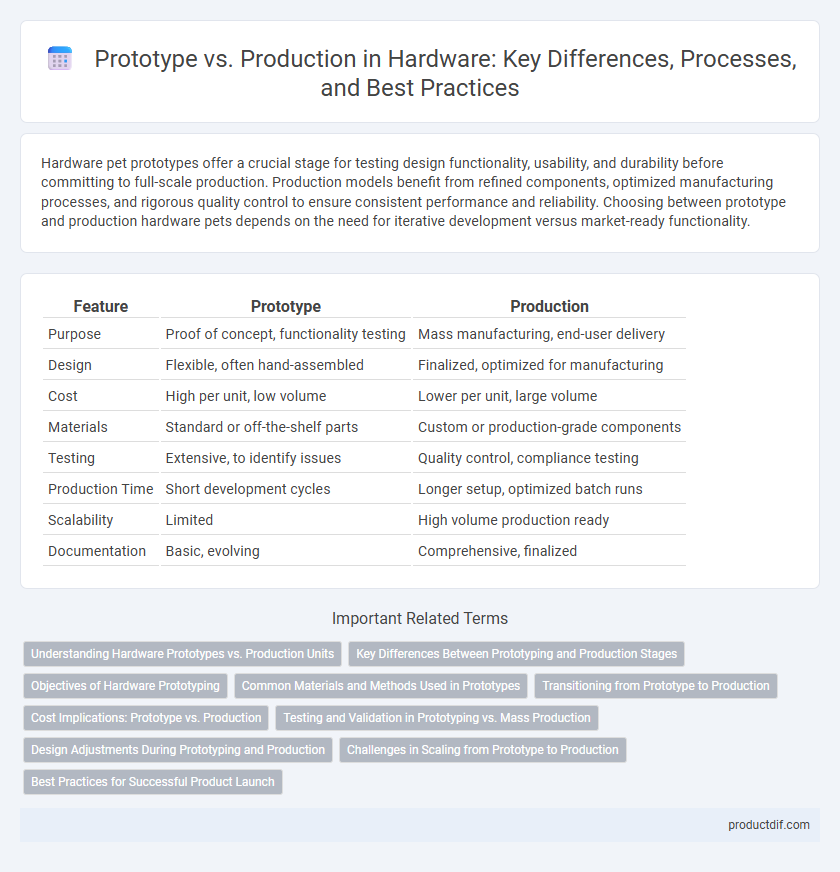

| Feature | Prototype | Production |

|---|---|---|

| Purpose | Proof of concept, functionality testing | Mass manufacturing, end-user delivery |

| Design | Flexible, often hand-assembled | Finalized, optimized for manufacturing |

| Cost | High per unit, low volume | Lower per unit, large volume |

| Materials | Standard or off-the-shelf parts | Custom or production-grade components |

| Testing | Extensive, to identify issues | Quality control, compliance testing |

| Production Time | Short development cycles | Longer setup, optimized batch runs |

| Scalability | Limited | High volume production ready |

| Documentation | Basic, evolving | Comprehensive, finalized |

Understanding Hardware Prototypes vs. Production Units

Hardware prototypes serve as early models for testing design concepts, functionality, and identifying potential issues before mass production. Production units are finalized, standardized hardware manufactured at scale, ensuring consistent quality, performance, and compliance with industry standards. Understanding the differences in materials, manufacturing processes, and testing rigor between prototypes and production units is crucial for successful hardware deployment.

Key Differences Between Prototyping and Production Stages

Prototyping involves creating an initial model to test functionality, design, and performance, often with limited materials and higher per-unit costs. Production focuses on mass manufacturing with optimized processes, cost efficiency, consistent quality, and scalability to meet market demand. Key differences include iteration speed, material selection, quality control standards, and production volume targets.

Objectives of Hardware Prototyping

Hardware prototyping aims to validate design concepts, identify potential flaws, and optimize performance before mass production. It enables hands-on testing of components and systems to ensure functionality, reliability, and manufacturability. Prototyping reduces development risks, shortens time-to-market, and supports iterative improvements based on real-world feedback.

Common Materials and Methods Used in Prototypes

Prototypes in hardware development commonly use materials like PLA, ABS, and resin due to their ease of rapid fabrication through 3D printing and CNC machining. Methods such as additive manufacturing and manual assembly allow for quick iteration and adjustments before committing to costly production tooling. These approaches prioritize flexibility and cost-efficiency over the durability and finish expected in final production units.

Transitioning from Prototype to Production

Transitioning from prototype to production involves refining design for manufacturability, ensuring component availability, and establishing quality control processes to meet large-scale demands. This phase requires thorough testing to identify potential failures, optimize assembly workflows, and reduce cost per unit while maintaining performance standards. Effective collaboration between engineering, supply chain, and manufacturing teams accelerates time-to-market and enhances product reliability.

Cost Implications: Prototype vs. Production

Prototype development incurs higher per-unit costs due to small batch sizes, specialized materials, and manual assembly processes, often requiring iterative design adjustments. Production escalates initial expenses with tooling, molds, and automation setup but dramatically lowers per-unit cost through economies of scale and streamlined manufacturing. Understanding these cost implications is critical for budgeting, as prototype expenses emphasize flexibility and innovation while production targets efficiency and mass-market affordability.

Testing and Validation in Prototyping vs. Mass Production

Testing and validation during prototyping focus on identifying functional issues and design flaws through iterative evaluations, often using limited, handcrafted units. In mass production, validation shifts to quality control and consistency, utilizing statistical process control and automated testing to ensure every unit meets specifications. This transition ensures scalability and reliability while maintaining performance standards across large volumes.

Design Adjustments During Prototyping and Production

Design adjustments during prototyping focus on identifying and resolving functional issues, optimizing component placement, and refining electrical performance to ensure the hardware meets initial specifications. In production, design changes prioritize manufacturability, cost reduction, and compliance with industry standards, often involving material substitutions and process optimizations. Effective iteration between prototyping and production stages minimizes errors, enhances product reliability, and streamlines scaling for mass manufacturing.

Challenges in Scaling from Prototype to Production

Scaling from prototype to production in hardware development involves overcoming significant challenges such as ensuring design reproducibility, managing component variability, and optimizing manufacturing processes for volume. Maintaining quality control while reducing costs requires extensive testing, supply chain coordination, and adapting prototypes to meet regulatory standards. Addressing these issues early is critical to achieving reliable performance and timely market delivery in mass production environments.

Best Practices for Successful Product Launch

Thorough testing and iterative prototyping are essential for identifying design flaws and optimizing hardware performance before full-scale production. Establishing clear documentation and maintaining consistent communication between development and manufacturing teams minimizes errors and ensures quality control. Early supplier engagement and scaling production processes responsibly reduce time-to-market risks and support a successful product launch.

Prototype vs Production Infographic

productdif.com

productdif.com