Lead-free solder offers environmental and health benefits by eliminating toxic lead content, making it compliant with RoHS regulations. It typically requires higher melting temperatures compared to leaded solder, which can affect component sensitivity and board reliability during assembly. Leaded solder remains favored for its excellent electrical conductivity and ease of use, especially in high-reliability applications.

Table of Comparison

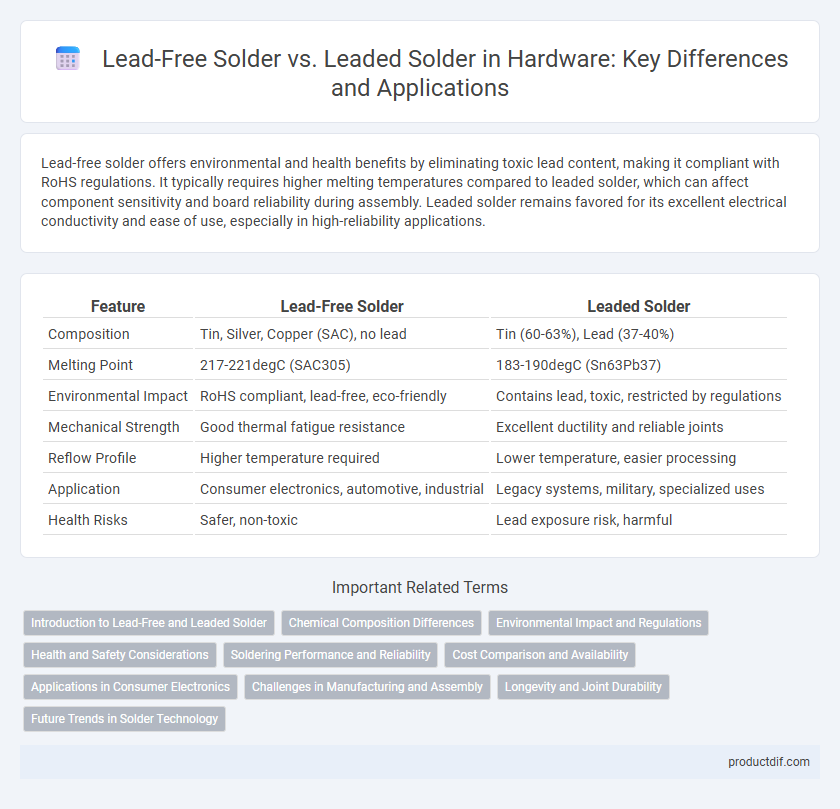

| Feature | Lead-Free Solder | Leaded Solder |

|---|---|---|

| Composition | Tin, Silver, Copper (SAC), no lead | Tin (60-63%), Lead (37-40%) |

| Melting Point | 217-221degC (SAC305) | 183-190degC (Sn63Pb37) |

| Environmental Impact | RoHS compliant, lead-free, eco-friendly | Contains lead, toxic, restricted by regulations |

| Mechanical Strength | Good thermal fatigue resistance | Excellent ductility and reliable joints |

| Reflow Profile | Higher temperature required | Lower temperature, easier processing |

| Application | Consumer electronics, automotive, industrial | Legacy systems, military, specialized uses |

| Health Risks | Safer, non-toxic | Lead exposure risk, harmful |

Introduction to Lead-Free and Leaded Solder

Lead-free solder commonly consists of tin combined with silver, copper, or bismuth, offering enhanced environmental safety compared to traditional leaded solder, which primarily contains tin and lead. Leaded solder, known for its lower melting point and excellent wetting properties, has historically facilitated reliable electrical connections in electronic hardware. Transitioning to lead-free solder addresses regulatory requirements like RoHS while maintaining durability and conductivity essential for modern electronic manufacturing.

Chemical Composition Differences

Lead-free solder primarily consists of a tin-based alloy combined with metals such as silver, copper, or bismuth, eliminating the toxic lead component found in traditional solders. Leaded solder typically contains about 60% tin and 40% lead, providing lower melting points and enhanced ductility compared to lead-free alternatives. The chemical composition differences impact solder joint reliability, melting temperature, and environmental compliance in electronic manufacturing.

Environmental Impact and Regulations

Lead-free solder significantly reduces hazardous waste and toxic lead emissions, aligning with global environmental regulations such as the Restriction of Hazardous Substances Directive (RoHS). Leaded solder, containing high levels of Pb, poses substantial risks to soil and water contamination, leading to stricter regulatory restrictions and disposal challenges. Transitioning to lead-free solder supports sustainable electronics manufacturing and compliance with international environmental standards.

Health and Safety Considerations

Lead-free solder is preferred in electronics manufacturing due to its reduced health risks compared to leaded solder, which contains toxic lead that can cause neurological damage and other serious health issues upon prolonged exposure. The use of lead-free alternatives like SAC alloys (tin-silver-copper) minimizes hazardous lead emissions during soldering processes, enhancing workplace safety. Proper ventilation and protective equipment remain essential to mitigate fumes and particle inhalation regardless of solder type.

Soldering Performance and Reliability

Lead-free solder typically offers higher melting temperatures, which can improve joint strength and thermal fatigue resistance in electronic assemblies. Leaded solder, with its lower melting point and superior wettability, often provides easier flow and stronger initial mechanical bonds, enhancing soldering performance for delicate components. Reliability tests indicate lead-free solder joints generally exhibit better long-term environmental stability but may face challenges with tin whisker growth, whereas leaded solder minimizes this risk, ensuring consistent electrical performance.

Cost Comparison and Availability

Lead-free solder generally incurs higher costs due to the use of more expensive metals like silver and copper, whereas leaded solder is cheaper because of its primary lead content. Leaded solder remains widely available and cost-effective, especially for large-scale manufacturing, while lead-free alternatives face supply fluctuations and higher prices influenced by stricter environmental regulations. The total cost of ownership for lead-free solder often includes additional equipment maintenance and process modifications, impacting overall production expenses.

Applications in Consumer Electronics

Lead-free solder is increasingly favored in consumer electronics due to its compliance with environmental regulations like RoHS, reducing the risk of lead poisoning and environmental contamination. It offers adequate mechanical strength and thermal conductivity for components such as smartphones, laptops, and televisions, although it requires higher melting temperatures and careful process control. Leaded solder remains in use for legacy devices and certain high-reliability applications, offering superior flow characteristics and lower melting points, which simplify assembly and improve joint reliability in sensitive consumer electronics manufacturing.

Challenges in Manufacturing and Assembly

Lead-free solder presents significant challenges in manufacturing and assembly due to its higher melting point compared to leaded solder, which can cause thermal stress on sensitive electronic components. The increased brittleness of lead-free solder joints often leads to reduced mechanical reliability and increased risk of micro-cracking during thermal cycling. Manufacturing processes must be adapted with precise temperature control and flux formulations to mitigate these issues and ensure consistent solder joint quality.

Longevity and Joint Durability

Lead-free solder typically offers superior joint durability due to its higher melting point and increased mechanical strength, enhancing the longevity of electronic assemblies in demanding environments. Leaded solder, while easier to work with due to its lower melting temperature, may experience faster degradation under thermal cycling and mechanical stress, potentially reducing long-term reliability. Selecting lead-free solder is often preferred for applications requiring extended service life and robust joint performance in hardware manufacturing.

Future Trends in Solder Technology

Future trends in solder technology emphasize the expansion of lead-free solder alloys due to environmental regulations such as RoHS and WEEE directives. Innovations in lead-free solders focus on improving joint reliability and thermal fatigue resistance by incorporating elements like bismuth, silver, and copper. Advanced formulations and nano-additives are poised to enhance solder performance for electronics in automotive, aerospace, and IoT applications, supporting higher temperature tolerances and miniaturization.

Lead-free solder vs Leaded solder Infographic

productdif.com

productdif.com