Rigid PCBs offer stable and durable circuit layouts ideal for applications requiring strong mechanical support and high-density component placement. Flex PCBs provide versatility with their bendable and lightweight design, making them perfect for compact devices and dynamic environments where space optimization is critical. Choosing between rigid and flex PCBs depends on the specific hardware pet's structural needs and performance requirements.

Table of Comparison

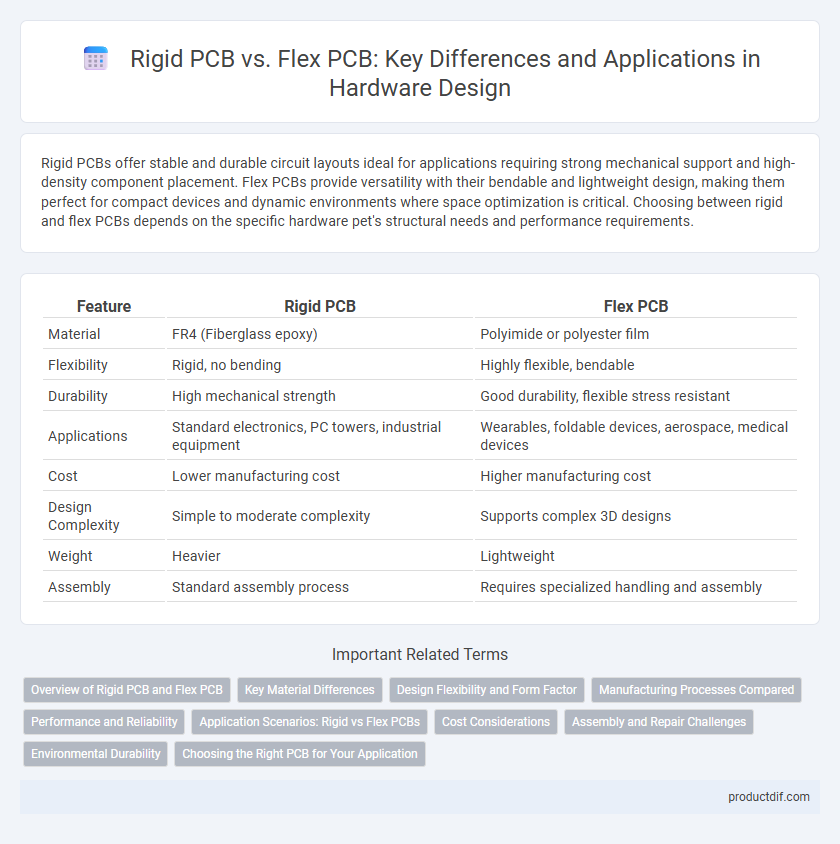

| Feature | Rigid PCB | Flex PCB |

|---|---|---|

| Material | FR4 (Fiberglass epoxy) | Polyimide or polyester film |

| Flexibility | Rigid, no bending | Highly flexible, bendable |

| Durability | High mechanical strength | Good durability, flexible stress resistant |

| Applications | Standard electronics, PC towers, industrial equipment | Wearables, foldable devices, aerospace, medical devices |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Design Complexity | Simple to moderate complexity | Supports complex 3D designs |

| Weight | Heavier | Lightweight |

| Assembly | Standard assembly process | Requires specialized handling and assembly |

Overview of Rigid PCB and Flex PCB

Rigid PCBs are made from solid, inflexible substrates like fiberglass, providing excellent durability and mechanical support for electronic components in fixed configurations. Flex PCBs use flexible polyimide or polyester films, allowing bending and folding, which enables compact designs and dynamic applications such as wearable devices and aerospace electronics. Both types serve distinct purposes in hardware design, with rigid boards dominating in high-strength environments and flex PCBs excelling in space-constrained and flexible assemblies.

Key Material Differences

Rigid PCBs are constructed from solid, inflexible substrates like fiberglass (FR4), providing durability and stability for static electronic arrangements. Flex PCBs use flexible materials such as polyimide or polyester films, allowing bending and dynamic applications without breaking. The key material difference lies in the substrate flexibility, where rigid boards ensure mechanical strength while flexible boards offer adaptability in compact or curved spaces.

Design Flexibility and Form Factor

Rigid PCBs offer a fixed, sturdy design that supports complex circuitry but limits shape adaptation, making them ideal for stable, flat installations. Flex PCBs provide exceptional design flexibility by conforming to irregular shapes and tight spaces, significantly reducing device size and weight. The form factor advantage of flex PCBs enables innovative product designs in compact and wearable electronics.

Manufacturing Processes Compared

Rigid PCBs require traditional manufacturing processes including drilling, etching, and lamination on a solid substrate like FR4, resulting in a durable and stable board ideal for complex, high-density circuits. Flex PCBs utilize flexible polymer substrates such as polyimide, with manufacturing involving precise layering, controlled lamination, and specialized etching to maintain flexibility and durability throughout bending cycles. The manufacturing of flex PCBs demands tighter process controls and specialized equipment to handle material stretch, bending tests, and dynamic electrical performance, differentiating it significantly from the rigid PCB production line.

Performance and Reliability

Rigid PCBs offer superior mechanical stability and consistent signal integrity, making them ideal for applications demanding high durability and precise electrical performance. Flex PCBs provide enhanced flexibility and vibration resistance, improving reliability in dynamic environments where bending or twisting occurs. Performance in rigid designs excels under static conditions, while flex PCBs ensure sustained connectivity and reduced mechanical failure in flexible or compact hardware installations.

Application Scenarios: Rigid vs Flex PCBs

Rigid PCBs are ideal for applications requiring strong structural support and durability, such as in desktop computers, power supplies, and automotive electronics where boards are exposed to minimal movement. Flex PCBs excel in dynamic environments like wearable devices, medical equipment, and aerospace systems due to their ability to bend and conform to complex shapes without compromising electrical performance. Combining rigid and flex PCBs enables hybrid solutions in smartphones and industrial robots, optimizing space while maintaining reliability and mechanical resilience.

Cost Considerations

Rigid PCBs generally have lower initial manufacturing costs due to standardized production processes and material availability, making them suitable for high-volume, cost-sensitive projects. Flex PCBs incur higher expenses because of specialized materials like polyimide and complex fabrication techniques required for bending and flexing capabilities. Cost factors also include assembly complexity and potential savings in space and weight, which may justify the higher upfront investment for flex PCBs in advanced electronic designs.

Assembly and Repair Challenges

Rigid PCBs offer straightforward assembly due to their solid structure, enabling easy component placement and soldering, but repairs can be difficult because of the risk of damaging the board during component removal. Flex PCBs present complex assembly challenges because of their delicate, bendable materials, requiring specialized handling and precise fixture setups to avoid damaging circuits. Repairing flex PCBs demands advanced techniques such as localized heating and reinforcement with adhesives to prevent further mechanical stress or breakage.

Environmental Durability

Rigid PCBs exhibit superior environmental durability due to their solid substrate, which offers enhanced resistance to moisture, heat, and mechanical stress. Flex PCBs provide flexibility but are more susceptible to damage from repeated bending, extreme temperatures, and exposure to harsh chemicals. Material composition and protective coatings significantly influence the longevity and performance of both rigid and flexible PCBs in challenging environmental conditions.

Choosing the Right PCB for Your Application

Choosing the right PCB for your application depends on factors such as space constraints, mechanical flexibility, and durability requirements. Rigid PCBs offer stable, high-density circuit layouts ideal for fixed, compact devices, while flexible PCBs enable bending and dynamic movement suitable for wearable technology and complex geometries. Evaluating temperature resistance, signal integrity, and manufacturing costs also guides the optimal selection between rigid and flex PCB designs.

Rigid PCB vs Flex PCB Infographic

productdif.com

productdif.com