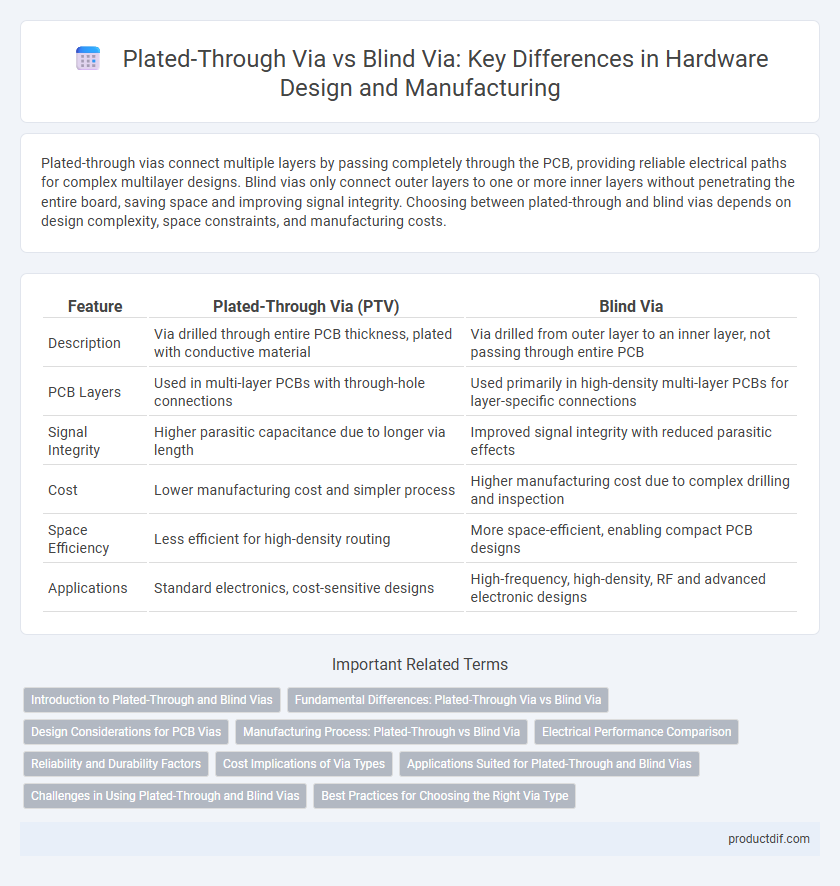

Plated-through vias connect multiple layers by passing completely through the PCB, providing reliable electrical paths for complex multilayer designs. Blind vias only connect outer layers to one or more inner layers without penetrating the entire board, saving space and improving signal integrity. Choosing between plated-through and blind vias depends on design complexity, space constraints, and manufacturing costs.

Table of Comparison

| Feature | Plated-Through Via (PTV) | Blind Via |

|---|---|---|

| Description | Via drilled through entire PCB thickness, plated with conductive material | Via drilled from outer layer to an inner layer, not passing through entire PCB |

| PCB Layers | Used in multi-layer PCBs with through-hole connections | Used primarily in high-density multi-layer PCBs for layer-specific connections |

| Signal Integrity | Higher parasitic capacitance due to longer via length | Improved signal integrity with reduced parasitic effects |

| Cost | Lower manufacturing cost and simpler process | Higher manufacturing cost due to complex drilling and inspection |

| Space Efficiency | Less efficient for high-density routing | More space-efficient, enabling compact PCB designs |

| Applications | Standard electronics, cost-sensitive designs | High-frequency, high-density, RF and advanced electronic designs |

Introduction to Plated-Through and Blind Vias

Plated-through vias (PTVs) are conductive pathways that extend through the entire printed circuit board (PCB), connecting multiple layers and enabling electrical signals to pass vertically. Blind vias connect outer layers to one or more inner layers without penetrating the entire board thickness, optimizing space for high-density PCBs. Both via types enhance circuit complexity and reliability while addressing different design and manufacturing needs.

Fundamental Differences: Plated-Through Via vs Blind Via

Plated-through vias (PTVs) extend through all layers of a printed circuit board (PCB), providing electrical connectivity from the top to the bottom layer, which ensures robust signal integrity and mechanical strength. Blind vias, on the other hand, only connect outer layers to one or more inner layers without penetrating the entire PCB thickness, helping to save board space and improve routing density in high-layer-count designs. The fundamental difference lies in the via depth and connectivity scope, where PTVs are through-hole and blind vias are partial-depth holes, influencing PCB complexity and fabrication cost.

Design Considerations for PCB Vias

Design considerations for PCB vias must account for electrical performance and manufacturing complexity when choosing between plated-through vias and blind vias. Plated-through vias provide robust interlayer connectivity but increase signal path length and parasitic inductance, impacting high-frequency applications. Blind vias reduce signal distortion by connecting outer layers to inner layers without passing through the entire board thickness, optimizing space in high-density designs.

Manufacturing Process: Plated-Through vs Blind Via

Plated-through vias (PTVs) are created by drilling holes through the entire printed circuit board (PCB) thickness and plating them with copper to establish electrical connections between all layers, requiring precise drilling and plating control for reliability. Blind vias, by contrast, connect only outer layers to one or more inner layers without penetrating the entire board, involving more complex laser or mechanical drilling confined to select layers and advanced plating techniques to ensure consistent electrical performance. The manufacturing process of plated-through vias is generally simpler and cost-effective, while blind vias require higher precision and specialized equipment, impacting PCB design flexibility and overall production cost.

Electrical Performance Comparison

Plated-through vias (PTVs) provide robust electrical connectivity by passing through the entire PCB thickness, ensuring consistent signal integrity and lower resistance for power distribution layers. Blind vias, which connect outer layers to one or more inner layers without penetrating the entire board, reduce parasitic capacitance and inductance, enhancing high-frequency performance and minimizing signal loss in dense multilayer designs. The choice between plated-through and blind vias directly impacts impedance control and crosstalk levels critical for high-speed circuit reliability.

Reliability and Durability Factors

Plated-through vias (PTVs) offer enhanced reliability by providing complete electrical connections through all PCB layers, reducing the risk of signal loss and mechanical failure in multilayer boards. Blind vias, penetrating only select layers, improve durability by minimizing stress and reducing the likelihood of cracks during thermal cycling, essential for high-density interconnects. Both via types must consider factors like copper plating thickness, via barrel quality, and surface finish to optimize long-term performance in harsh operating environments.

Cost Implications of Via Types

Plated-through vias (PTVs) generally incur higher manufacturing costs due to the extensive drilling and plating processes required to create holes that extend through all PCB layers, increasing material use and production time. Blind vias, which only connect outer layers to one or more inner layers without penetrating the entire board, can reduce material costs and save board space, but their more complex fabrication process often results in higher per-unit costs for high-density interconnect PCBs. Evaluating cost implications involves balancing the expense of deeper drilling in PTVs against the precision and layering advantages of blind vias, which impact both the initial manufacturing budget and overall PCB performance.

Applications Suited for Plated-Through and Blind Vias

Plated-through vias are ideal for multilayer printed circuit boards requiring electrical connections through all layers, commonly used in complex devices like motherboards and industrial control systems. Blind vias connect outer layers to one or more inner layers without passing through the entire board, making them suitable for high-density applications such as smartphones and compact electronic devices. These vias optimize space and improve signal integrity in designs where board real estate and performance are critical.

Challenges in Using Plated-Through and Blind Vias

Plated-through vias pose challenges such as increased parasitic capacitance and potential signal integrity issues due to their full-hole structure connecting multiple PCB layers. Blind vias, while minimizing layer-to-layer interference, present manufacturing difficulties including higher cost, complex drilling processes, and limited inspection capabilities. Both via types require careful design considerations to mitigate thermal stress and maintain reliability in high-density circuit boards.

Best Practices for Choosing the Right Via Type

Selecting the appropriate via type in PCB design depends on factors like signal integrity, board space, and manufacturing cost. Plated-through vias offer robust electrical connections through the entire board thickness, ideal for multi-layer designs requiring high reliability, while blind vias connect outer layers to inner layers without passing through the whole board, saving space and improving performance in high-density layouts. Best practices include assessing layer count, electrical requirements, and mechanical constraints to optimize via placement and ensure signal quality and manufacturability.

Plated-through via vs Blind via Infographic

productdif.com

productdif.com