Thru-hole components are mounted by inserting leads through drilled holes on the PCB, providing strong mechanical bonds ideal for high-stress applications. Surface-mount devices (SMD) offer compact size and higher circuit density by soldering directly onto the PCB surface, enabling faster automated assembly. SMD technology is preferred in modern electronics for its efficiency and performance, while thru-hole is chosen for durability and ease of prototyping.

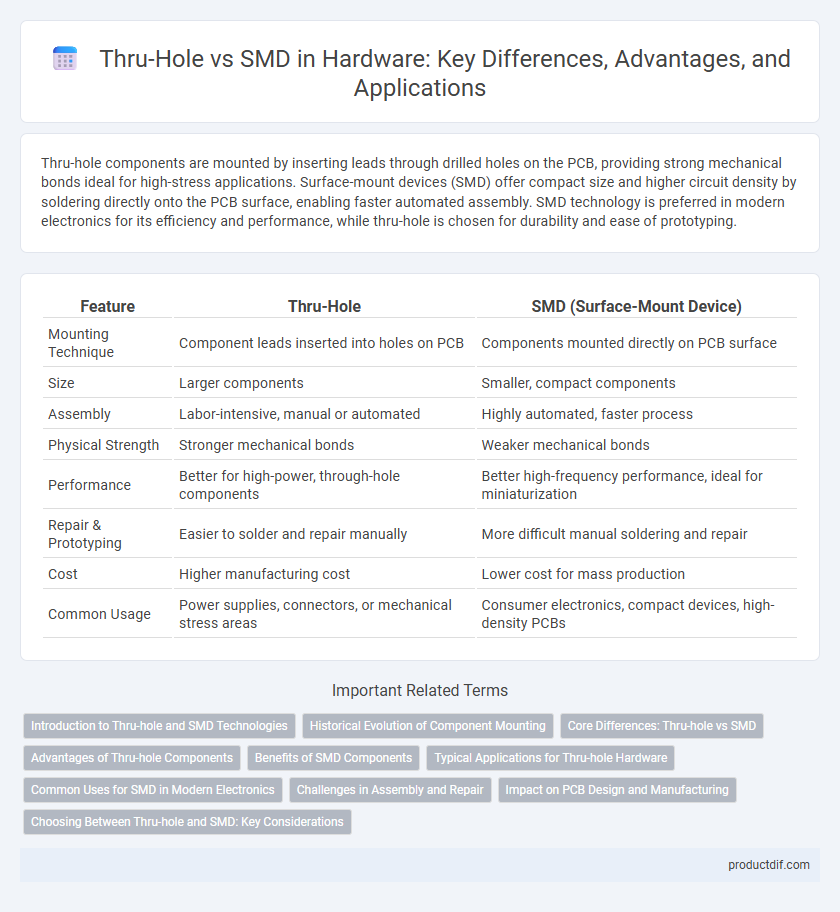

Table of Comparison

| Feature | Thru-Hole | SMD (Surface-Mount Device) |

|---|---|---|

| Mounting Technique | Component leads inserted into holes on PCB | Components mounted directly on PCB surface |

| Size | Larger components | Smaller, compact components |

| Assembly | Labor-intensive, manual or automated | Highly automated, faster process |

| Physical Strength | Stronger mechanical bonds | Weaker mechanical bonds |

| Performance | Better for high-power, through-hole components | Better high-frequency performance, ideal for miniaturization |

| Repair & Prototyping | Easier to solder and repair manually | More difficult manual soldering and repair |

| Cost | Higher manufacturing cost | Lower cost for mass production |

| Common Usage | Power supplies, connectors, or mechanical stress areas | Consumer electronics, compact devices, high-density PCBs |

Introduction to Thru-hole and SMD Technologies

Thru-hole and Surface-Mount Device (SMD) technologies are fundamental methods for mounting electronic components onto printed circuit boards (PCBs). Thru-hole technology involves inserting component leads into drilled holes on the PCB and soldering them on the opposite side, offering strong mechanical bonds ideal for high-reliability applications. SMD technology attaches components directly onto the PCB surface without holes, enabling higher component density, improved electrical performance, and suitability for automated assembly processes.

Historical Evolution of Component Mounting

Thru-hole technology, developed in the 1940s, dominated early electronic assembly with components inserted through drilled holes and soldered on the PCB's opposite side, offering strong mechanical bonds ideal for heavy components. Surface-mount technology (SMT) emerged in the late 1960s, enabling much smaller, lighter, and higher-density circuit designs by placing components directly on the PCB surface without requiring drilled holes. This evolution from thru-hole to SMD revolutionized manufacturing efficiency, miniaturization, and automation in hardware production.

Core Differences: Thru-hole vs SMD

Thru-hole technology involves inserting component leads into holes drilled through the PCB, providing strong mechanical bonds ideal for high-stress applications. Surface Mount Devices (SMD) are mounted directly onto the PCB surface, enabling higher component density and automated assembly processes. Thru-hole is preferred for durability and prototype testing, while SMD excels in compact designs and mass production efficiency.

Advantages of Thru-hole Components

Thru-hole components offer superior mechanical strength and durability, making them ideal for applications requiring robust physical connections and high reliability under stress or vibration. Their easier manual soldering and inspection processes contribute to simpler prototyping and repair compared to surface-mount devices (SMD). These advantages make thru-hole technology preferable in aerospace, automotive, and industrial equipment where component stability is critical.

Benefits of SMD Components

Surface-mount device (SMD) components offer significant advantages over thru-hole technology, including smaller size and higher component density, which enable more compact and lightweight circuit board designs. SMDs support automated assembly processes, resulting in faster production times and reduced labor costs. Their improved electrical performance and lower parasitic inductance enhance signal integrity, making them ideal for high-frequency applications.

Typical Applications for Thru-hole Hardware

Thru-hole hardware is commonly used in applications requiring strong mechanical bonds, such as power supplies, automotive electronics, and industrial equipment. It is preferred for components like connectors, transformers, and large capacitors due to its durability and ability to withstand high stress and vibration. Thru-hole technology also facilitates prototyping and testing because of easier manual soldering and assembly.

Common Uses for SMD in Modern Electronics

Surface-mount devices (SMD) are predominantly used in modern electronics for applications requiring high-density circuit boards, such as smartphones, laptops, and wearable technology. Their compact size and ease of automated assembly make them ideal for mass production of consumer electronics, automotive systems, and industrial control equipment. SMD components also enable improved electrical performance and reduced parasitic inductance, which is crucial in high-frequency and miniaturized circuits.

Challenges in Assembly and Repair

Thru-hole components require drilling holes in the PCB, increasing assembly complexity and time compared to SMD components, which mount directly on the surface. Repairing thru-hole components is labor-intensive due to the soldering on both sides of the board, while SMD challenges include the difficulty of precise placement and the risk of thermal damage during reflow soldering. Additionally, thru-hole assemblies offer stronger mechanical bonds, but SMD technology allows for higher component density and automation efficiency despite intricate repair processes.

Impact on PCB Design and Manufacturing

Thru-hole components require drilled holes on the PCB, increasing manufacturing complexity, cost, and limiting component density, while SMD components allow for more compact designs with higher circuit density due to their smaller size and surface mount nature. The use of thru-hole technology often results in more robust mechanical connections, making it suitable for high-stress applications, whereas SMD favors automated assembly, reducing production time and labor costs. PCB design with SMD enables multi-layer boards with finer traces, improving electrical performance and enabling advanced miniaturization in modern electronics.

Choosing Between Thru-hole and SMD: Key Considerations

Choosing between thru-hole and Surface Mount Device (SMD) components depends on factors such as mechanical strength, assembly complexity, and space constraints. Thru-hole components offer superior mechanical bonding, making them ideal for applications requiring durability and high power dissipation. SMD components provide higher density and smaller footprints suitable for compact, high-speed, and automated manufacturing environments.

Thru-hole vs SMD Infographic

productdif.com

productdif.com