Shielded enclosures provide superior protection against electromagnetic interference (EMI), ensuring sensitive hardware components maintain optimal performance and reliability in noisy environments. Unshielded enclosures offer basic protection but are more susceptible to external EMI, which can lead to signal degradation and potential hardware malfunctions. Choosing between shielded and unshielded enclosures depends largely on the specific application's sensitivity to EMI and environmental conditions.

Table of Comparison

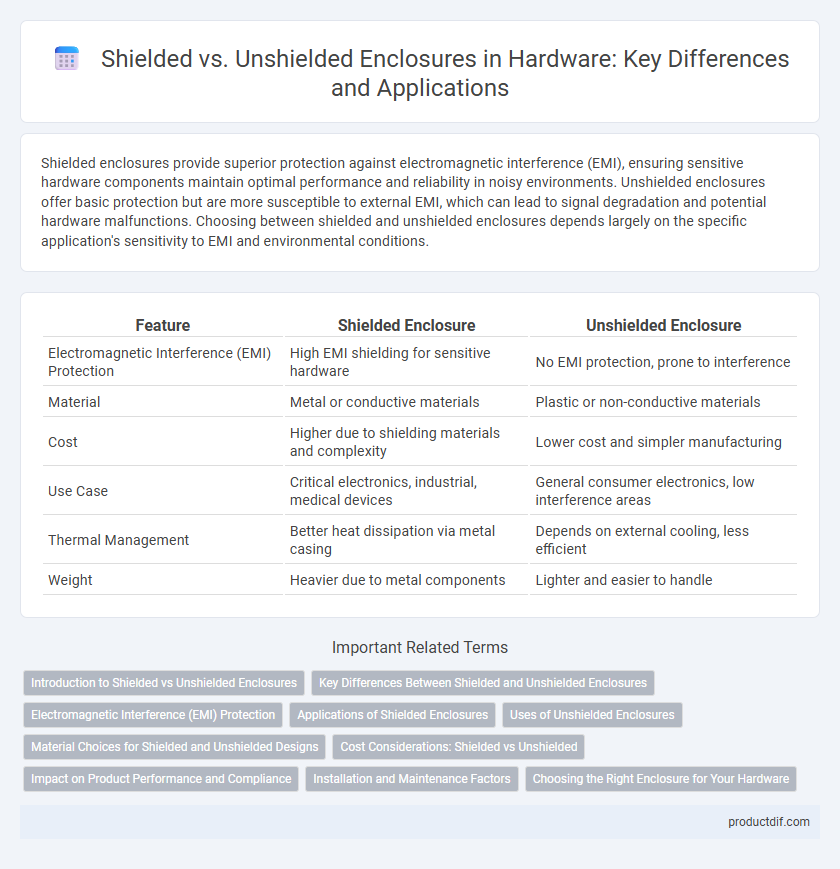

| Feature | Shielded Enclosure | Unshielded Enclosure |

|---|---|---|

| Electromagnetic Interference (EMI) Protection | High EMI shielding for sensitive hardware | No EMI protection, prone to interference |

| Material | Metal or conductive materials | Plastic or non-conductive materials |

| Cost | Higher due to shielding materials and complexity | Lower cost and simpler manufacturing |

| Use Case | Critical electronics, industrial, medical devices | General consumer electronics, low interference areas |

| Thermal Management | Better heat dissipation via metal casing | Depends on external cooling, less efficient |

| Weight | Heavier due to metal components | Lighter and easier to handle |

Introduction to Shielded vs Unshielded Enclosures

Shielded enclosures are designed to protect electronic components from electromagnetic interference (EMI) by using conductive materials such as metal or coated plastics, ensuring optimal signal integrity and device performance. Unshielded enclosures, typically made from non-conductive materials like plastic, allow for greater design flexibility and cost-efficiency but may expose sensitive hardware to EMI risks. The choice between shielded and unshielded enclosures depends on specific application requirements, environmental conditions, and the necessity for electromagnetic compatibility (EMC).

Key Differences Between Shielded and Unshielded Enclosures

Shielded enclosures provide enhanced electromagnetic interference (EMI) protection by utilizing conductive materials that block external signals, making them ideal for sensitive electronic components. Unshielded enclosures lack this protective layer, exposing internal hardware to potential EMI and increasing vulnerability in environments with high electromagnetic noise. The choice between shielded and unshielded enclosures hinges on the required level of EMI resilience and environmental conditions where the hardware operates.

Electromagnetic Interference (EMI) Protection

Shielded enclosures provide superior protection against Electromagnetic Interference (EMI) by incorporating conductive materials like copper or aluminum that block external electromagnetic waves from affecting sensitive electronic components. Unshielded enclosures lack this conductive barrier, making devices more vulnerable to EMI, which can cause data corruption, signal degradation, and hardware malfunction. Choosing shielded enclosures is essential in environments with high electromagnetic noise to ensure device reliability and performance.

Applications of Shielded Enclosures

Shielded enclosures are essential in applications requiring protection against electromagnetic interference (EMI) and radio frequency interference (RFI), such as in aerospace, medical devices, and telecommunications. These enclosures ensure signal integrity and reduce noise in sensitive electronic equipment, improving performance and reliability. Industries dealing with high-frequency circuits or critical data transmission often mandate shielded enclosures for compliance with regulatory standards.

Uses of Unshielded Enclosures

Unshielded enclosures are primarily used in environments where electromagnetic interference (EMI) is minimal or non-critical, such as residential and light commercial settings. They provide basic protection against dust and physical damage, making them suitable for general-purpose electrical and electronic housing. Cost-effective and lightweight, unshielded enclosures support easy installation and maintenance without the need for specialized grounding or shielding materials.

Material Choices for Shielded and Unshielded Designs

Shielded enclosures typically use conductive materials such as aluminum, steel, or copper to block electromagnetic interference (EMI) and ensure signal integrity, while unshielded enclosures often rely on plastic or non-conductive materials to reduce cost and weight without EMI protection. Metal alloys with high conductivity and corrosion resistance are preferred for shielded designs to maintain durability and effective shielding performance in industrial environments. Plastic composites, ABS, and PVC are common choices for unshielded enclosures, offering flexibility and ease of manufacturing but limited protection against electromagnetic noise.

Cost Considerations: Shielded vs Unshielded

Shielded enclosures typically incur higher initial costs due to the use of specialized materials like metal alloys and added manufacturing processes designed to block electromagnetic interference (EMI). Unshielded enclosures are more cost-effective, leveraging simpler materials such as plastic or standard metal without additional EMI protection, resulting in lower production expenses. Long-term costs may vary based on application requirements, where shielded enclosures reduce maintenance related to EMI issues and potential system failures.

Impact on Product Performance and Compliance

Shielded enclosures significantly enhance product performance by minimizing electromagnetic interference (EMI), ensuring stable signal integrity and reduced noise in sensitive hardware components. Compliance with regulatory standards such as FCC and CE is more easily achieved using shielded enclosures, as they prevent electromagnetic emissions from exceeding allowed limits. In contrast, unshielded enclosures may lead to increased susceptibility to external interference and potential non-compliance with industry regulations, impacting overall device reliability and market approval.

Installation and Maintenance Factors

Shielded enclosures require careful installation to ensure proper grounding and electromagnetic interference (EMI) containment, often involving specialized tools and skilled labor, which can increase initial setup time and costs. Maintenance of shielded enclosures includes regular inspection of seals and grounding connections to maintain EMI protection effectiveness, often necessitating trained technicians. Unshielded enclosures offer easier installation and lower maintenance requirements, as they do not require EMI-specific measures, making them cost-effective for environments with minimal interference concerns.

Choosing the Right Enclosure for Your Hardware

Selecting the right enclosure for your hardware depends on the specific environment and electromagnetic interference (EMI) considerations. Shielded enclosures offer superior protection against EMI, making them ideal for sensitive electronic components in high-interference environments. Unshielded enclosures provide cost-effective protection primarily against physical damage and dust but may not prevent signal disruptions caused by EMI.

Shielded enclosure vs Unshielded enclosure Infographic

productdif.com

productdif.com