Copper traces in traditional rigid PCBs provide excellent electrical conductivity and mechanical stability for high-performance hardware applications. Flex PCBs offer superior flexibility and space-saving advantages, enabling complex designs in compact devices without compromising signal integrity. The choice between copper trace and flex PCB depends on the required durability, bending radius, and application-specific form factor constraints.

Table of Comparison

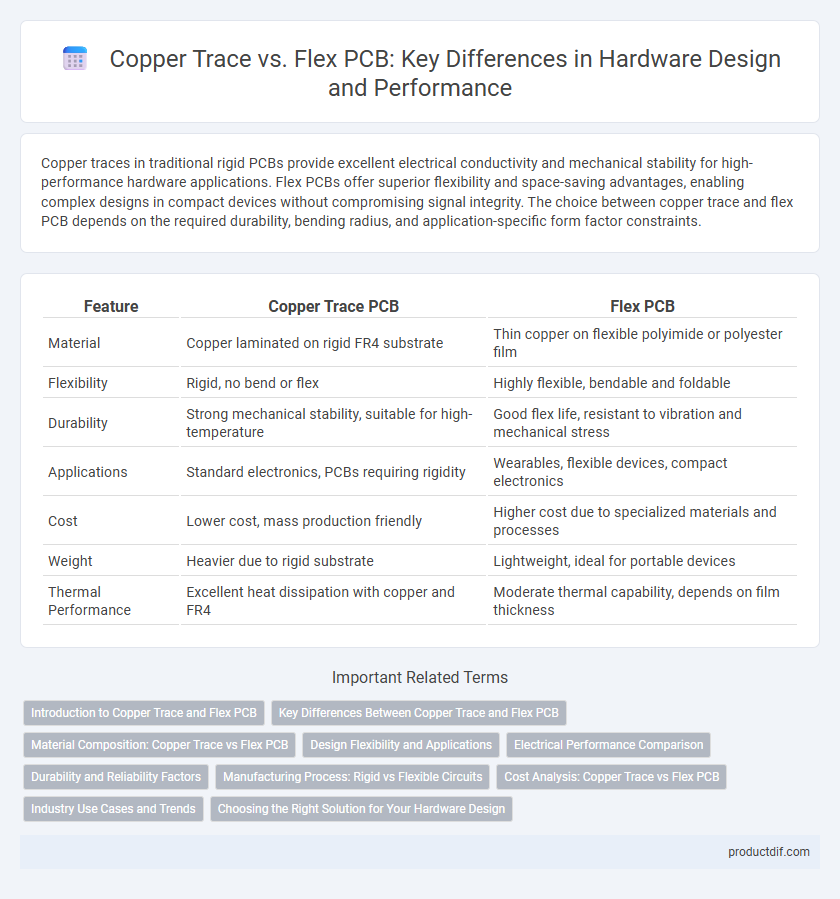

| Feature | Copper Trace PCB | Flex PCB |

|---|---|---|

| Material | Copper laminated on rigid FR4 substrate | Thin copper on flexible polyimide or polyester film |

| Flexibility | Rigid, no bend or flex | Highly flexible, bendable and foldable |

| Durability | Strong mechanical stability, suitable for high-temperature | Good flex life, resistant to vibration and mechanical stress |

| Applications | Standard electronics, PCBs requiring rigidity | Wearables, flexible devices, compact electronics |

| Cost | Lower cost, mass production friendly | Higher cost due to specialized materials and processes |

| Weight | Heavier due to rigid substrate | Lightweight, ideal for portable devices |

| Thermal Performance | Excellent heat dissipation with copper and FR4 | Moderate thermal capability, depends on film thickness |

Introduction to Copper Trace and Flex PCB

Copper traces serve as the primary conductive pathways on traditional rigid PCBs, providing reliable electrical connectivity and excellent thermal management due to copper's high conductivity. Flex PCBs utilize thin, flexible copper traces laminated onto a flexible polymer substrate, enabling complex shapes and dynamic bending in applications such as wearable devices and aerospace electronics. The choice between copper trace rigid boards and flexible PCB designs hinges on mechanical flexibility requirements, space constraints, and durability in dynamic environments.

Key Differences Between Copper Trace and Flex PCB

Copper traces are rigid conductive pathways etched onto traditional PCBs, providing high durability and excellent electrical performance in stable environments. Flex PCBs use flexible substrates with copper traces that enable bending and folding, ideal for compact and dynamic applications requiring space savings and mechanical flexibility. The primary difference lies in substrate flexibility and application suitability, with copper traces fixed on rigid boards, while flex PCBs support movement without compromising circuit integrity.

Material Composition: Copper Trace vs Flex PCB

Copper traces in rigid PCBs consist primarily of pure copper layers laminated onto a fiberglass substrate, providing excellent electrical conductivity and mechanical stability. Flex PCBs incorporate copper traces embedded within flexible polymer films, such as polyimide or polyester, offering enhanced bendability and resistance to mechanical stress. The differing substrate materials significantly impact thermal performance, durability, and application suitability between copper traces on rigid and flexible circuit boards.

Design Flexibility and Applications

Copper trace in rigid PCBs offers high conductivity and durability but limits design flexibility due to fixed board shapes and thickness. Flex PCBs incorporate copper traces on flexible substrates, enabling dynamic bending, twisting, and three-dimensional configurations suitable for compact, wearable, and complex electronics. This flexibility allows integration in aerospace, medical devices, and consumer electronics where space constraints and motion require adaptable circuitry.

Electrical Performance Comparison

Copper traces in rigid PCBs provide superior electrical conductivity and lower resistance compared to flex PCBs, enabling higher current capacity and reduced signal loss. Flex PCBs often use thinner copper layers and may introduce impedance variations due to bending, impacting high-frequency signal integrity. Optimizing trace width, copper thickness, and substrate materials is critical to balancing electrical performance in both rigid and flex circuit designs.

Durability and Reliability Factors

Copper traces in rigid PCBs offer superior durability due to their solid, thick conductive pathways that resist physical wear and environmental stress better than the thin, flexible copper layers in flex PCBs. Flex PCBs provide enhanced reliability in dynamic applications by accommodating bending and vibration without fracture, but their thinner copper traces are more susceptible to fatigue over repeated flex cycles. Material composition, environmental exposure, and mechanical stress are critical factors influencing the lifespan and performance stability of copper traces in both rigid and flex PCB designs.

Manufacturing Process: Rigid vs Flexible Circuits

Copper trace manufacturing for rigid PCBs involves etching stable copper layers on solid substrates like FR-4, ensuring high precision and durability for static electronic components. Flex PCB production uses thin, flexible polyimide or polyester film substrates allowing copper traces to bend and withstand repeated flexing without cracking. The flexible circuit manufacturing process requires specialized lamination and etching techniques to maintain electrical integrity in dynamic and space-constrained applications.

Cost Analysis: Copper Trace vs Flex PCB

Copper trace PCBs typically offer lower production costs due to simpler manufacturing processes and standardized materials, making them ideal for high-volume, cost-sensitive electronics. Flex PCBs involve higher expenses stemming from specialized substrates and complex fabrication techniques that enable unique form factors and dynamic bending capabilities. Cost analysis reveals that while copper trace PCBs excel in affordability for rigid designs, flex PCBs justify their premium through enhanced performance and design flexibility in compact, flexible applications.

Industry Use Cases and Trends

Copper traces in rigid PCBs offer superior electrical conductivity and mechanical strength, making them ideal for high-frequency and high-power industrial applications such as aerospace and automotive electronics. Flex PCBs provide enhanced flexibility and space-saving advantages, widely adopted in wearable technology, medical devices, and compact consumer electronics where dynamic bending and lightweight design are critical. Industry trends indicate increasing integration of flex PCB solutions with rigid copper trace components to achieve hybrid designs that balance durability with flexibility in advanced manufacturing.

Choosing the Right Solution for Your Hardware Design

Copper trace PCBs offer exceptional electrical conductivity and durability, making them ideal for high-performance, rigid hardware applications requiring stable signal integrity. Flex PCBs provide superior flexibility and lightweight design, perfect for compact devices and dynamic environments where space constraints and mechanical bending are critical factors. Selecting the right solution depends on balancing electrical requirements, mechanical flexibility, and form factor constraints to optimize overall device functionality.

Copper trace vs Flex PCB Infographic

productdif.com

productdif.com