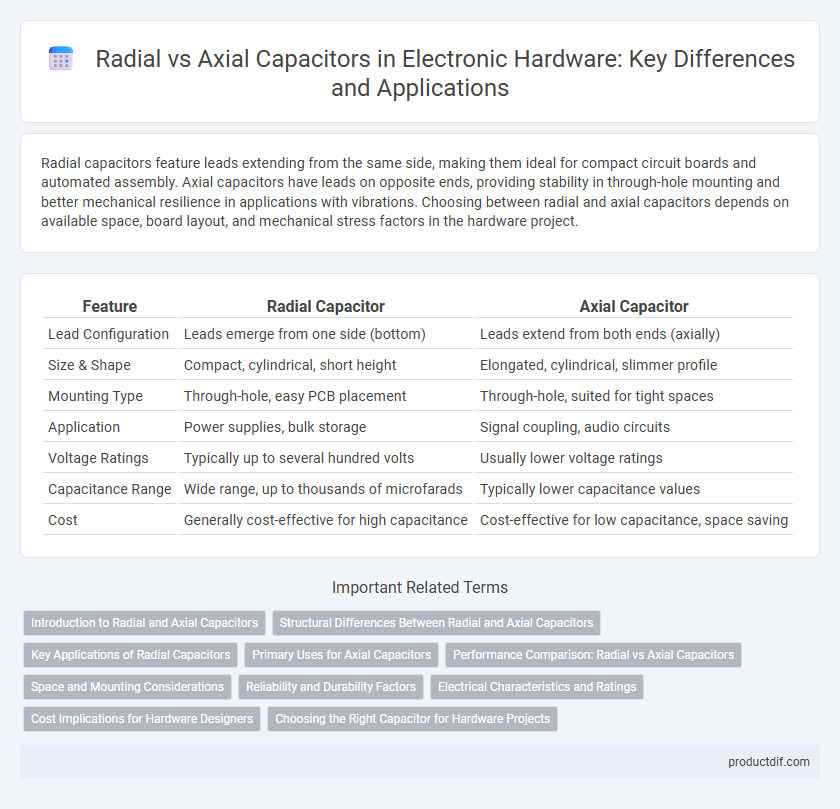

Radial capacitors feature leads extending from the same side, making them ideal for compact circuit boards and automated assembly. Axial capacitors have leads on opposite ends, providing stability in through-hole mounting and better mechanical resilience in applications with vibrations. Choosing between radial and axial capacitors depends on available space, board layout, and mechanical stress factors in the hardware project.

Table of Comparison

| Feature | Radial Capacitor | Axial Capacitor |

|---|---|---|

| Lead Configuration | Leads emerge from one side (bottom) | Leads extend from both ends (axially) |

| Size & Shape | Compact, cylindrical, short height | Elongated, cylindrical, slimmer profile |

| Mounting Type | Through-hole, easy PCB placement | Through-hole, suited for tight spaces |

| Application | Power supplies, bulk storage | Signal coupling, audio circuits |

| Voltage Ratings | Typically up to several hundred volts | Usually lower voltage ratings |

| Capacitance Range | Wide range, up to thousands of microfarads | Typically lower capacitance values |

| Cost | Generally cost-effective for high capacitance | Cost-effective for low capacitance, space saving |

Introduction to Radial and Axial Capacitors

Radial capacitors feature leads extending from the same side, enabling compact PCB layouts and better stability in automated assembly processes. Axial capacitors have leads on opposite ends, making them ideal for inline mounting and through-hole applications requiring easy wire connections. Both types serve distinct roles in hardware design, chosen based on space constraints and circuit configuration.

Structural Differences Between Radial and Axial Capacitors

Radial capacitors feature leads extending from one side of the cylindrical body, facilitating vertical mounting on PCBs and offering a compact footprint ideal for dense circuit designs. Axial capacitors have leads protruding from both ends of the cylindrical body, enabling horizontal mounting that suits through-hole applications and provides stability in mechanical stress environments. The distinct lead arrangements directly influence mounting orientation, space utilization, and mechanical reliability in electronic assemblies.

Key Applications of Radial Capacitors

Radial capacitors are widely used in power supply circuits, signal processing, and audio equipment due to their compact size and high capacitance values. Their lead configuration allows for efficient mounting on printed circuit boards, making them ideal for applications requiring enhanced stability and reliability under varying electrical loads. These capacitors excel in filtering, decoupling, and energy storage roles, particularly in consumer electronics and industrial control systems.

Primary Uses for Axial Capacitors

Axial capacitors are primarily used in applications requiring stable capacitance values and reliable performance in compact, long, and narrow spaces such as in signal coupling, filtering, and timing circuits. Their lead configuration allows for easy insertion into through-hole circuit boards, making them ideal for axial mounting in vintage audio equipment, power supplies, and printed circuit boards (PCBs) requiring precise and low-noise capacitor functions. These capacitors excel in high-frequency signal processing and are favored in audio and analog circuits where maintaining signal integrity is critical.

Performance Comparison: Radial vs Axial Capacitors

Radial capacitors generally offer higher capacitance values and improved thermal performance compared to axial capacitors, making them suitable for high-frequency applications and dense PCB layouts. Axial capacitors provide better mechanical stability and are preferred in through-hole mounting scenarios where lead strength and vibration resistance are critical. Performance differences include ESR (Equivalent Series Resistance) and ESL (Equivalent Series Inductance), with radial capacitors typically exhibiting lower ESL, enhancing their efficiency in power electronics and signal filtering.

Space and Mounting Considerations

Radial capacitors feature leads extending from the same side, allowing for compact, vertical mounting that saves PCB surface space, ideal for densely populated circuits. Axial capacitors have leads on opposite ends, enabling them to lie flat along the board, which is beneficial for low-profile designs and through-hole mounting on narrow spaces. Space optimization and mechanical stability depend on the capacitor orientation, with radial types preferred for vertical stacking and axial types suited for elongated, horizontal layouts.

Reliability and Durability Factors

Radial capacitors generally offer higher reliability and durability due to their robust construction and better heat dissipation, making them ideal for applications with mechanical stress and vibrations. Axial capacitors, while compact and suitable for tight spaces, may have lower durability in high-stress environments due to their elongated leads prone to bending and fatigue. The choice between radial and axial capacitors should consider operational temperature range, mechanical stability, and lifecycle requirements to ensure optimal performance in hardware designs.

Electrical Characteristics and Ratings

Radial capacitors typically have higher volumetric efficiency and can offer greater capacitance values at the same rated voltage compared to axial capacitors, making them ideal for compact circuit designs. Axial capacitors generally feature lower ESR (Equivalent Series Resistance) and are preferred for applications requiring stable frequency characteristics and reliable mechanical mounting. Voltage ratings for both types vary widely, but radial capacitors often accommodate higher ripple currents, while axial capacitors excel in environments with vibration due to their lead configuration.

Cost Implications for Hardware Designers

Radial capacitors generally offer lower manufacturing costs due to simpler assembly and smaller size, making them ideal for high-volume production in compact hardware designs. Axial capacitors often incur higher expenses because of their elongated shape, which requires more space on the PCB and potentially more complex handling during assembly. Hardware designers must weigh these cost implications against design constraints and performance requirements to optimize both budget and functionality.

Choosing the Right Capacitor for Hardware Projects

Radial capacitors offer a compact footprint and are ideal for circuit boards with limited space, while axial capacitors provide easier installation in through-hole designs and better mechanical stability in linear layouts. Selecting the right capacitor depends on project requirements such as voltage rating, capacitance, and physical orientation constraints. Understanding these differences ensures optimal performance and reliability in hardware projects focusing on power supply filtering, signal coupling, or timing applications.

Radial Capacitor vs Axial Capacitor Infographic

productdif.com

productdif.com