THT soldering involves inserting component leads through holes on a printed circuit board and then soldering them on the opposite side, providing strong mechanical bonds ideal for heavy or high-stress components. SMT soldering places components directly onto the PCB surface without leads, allowing for higher component density and automation compatibility. Selecting between THT and SMT soldering depends on factors such as component type, mechanical strength requirements, and manufacturing volume.

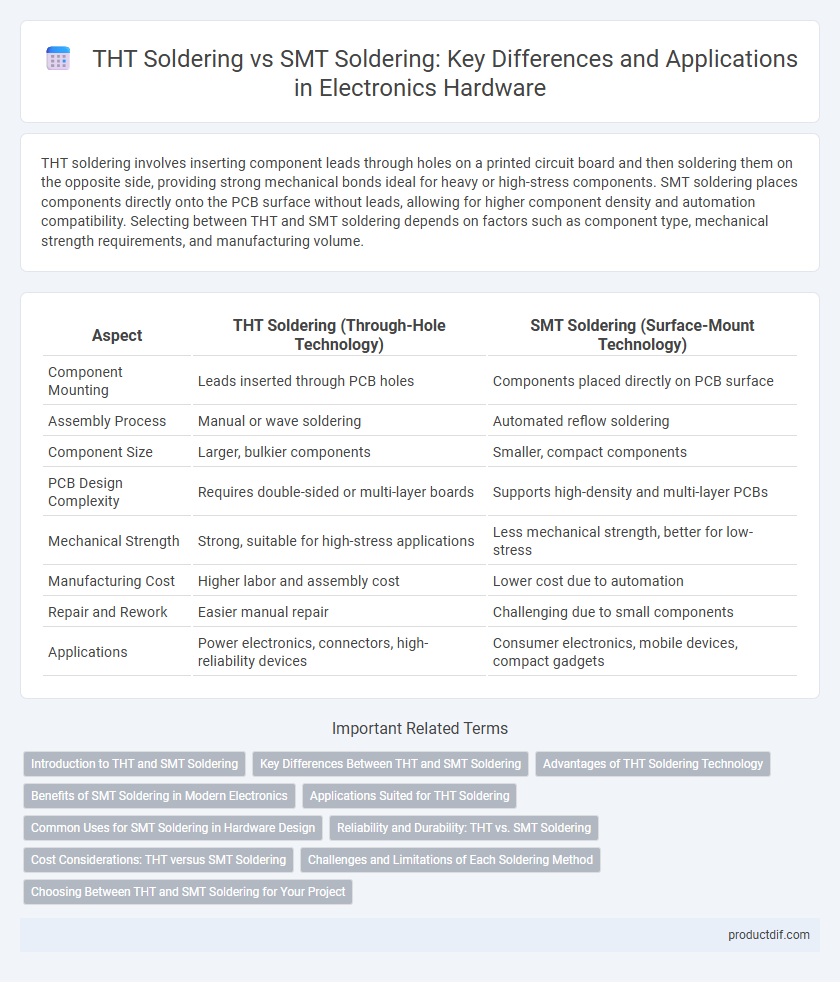

Table of Comparison

| Aspect | THT Soldering (Through-Hole Technology) | SMT Soldering (Surface-Mount Technology) |

|---|---|---|

| Component Mounting | Leads inserted through PCB holes | Components placed directly on PCB surface |

| Assembly Process | Manual or wave soldering | Automated reflow soldering |

| Component Size | Larger, bulkier components | Smaller, compact components |

| PCB Design Complexity | Requires double-sided or multi-layer boards | Supports high-density and multi-layer PCBs |

| Mechanical Strength | Strong, suitable for high-stress applications | Less mechanical strength, better for low-stress |

| Manufacturing Cost | Higher labor and assembly cost | Lower cost due to automation |

| Repair and Rework | Easier manual repair | Challenging due to small components |

| Applications | Power electronics, connectors, high-reliability devices | Consumer electronics, mobile devices, compact gadgets |

Introduction to THT and SMT Soldering

THT (Through-Hole Technology) soldering involves inserting electronic components with leads through drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, offering strong mechanical bonds ideal for components subject to physical stress. SMT (Surface-Mount Technology) soldering places components directly onto the PCB surface, allowing for higher component density and automated assembly processes, which enhances production speed and reduces manufacturing costs. Both methods are essential in modern electronics manufacturing, with THT favored for durability in complex assemblies and SMT preferred for compact, high-volume applications.

Key Differences Between THT and SMT Soldering

THT soldering involves mounting components with leads through drilled holes on the PCB, providing strong mechanical bonds ideal for heavy or high-stress parts, while SMT soldering attaches components directly onto the PCB surface, enabling higher component density and faster automated assembly. THT soldering typically requires more manual labor and longer processing times compared to the rapid, highly automated SMT process. The choice between THT and SMT depends on factors such as component size, circuit complexity, manufacturing volume, and mechanical robustness requirements.

Advantages of THT Soldering Technology

Through-Hole Technology (THT) soldering offers superior mechanical strength and durability due to its lead wire passing through the PCB, making it ideal for components subjected to mechanical stress or high power. THT provides reliable connections in harsh environments, improving resistance to vibration, thermal cycling, and physical impact. Its ease of inspection and repair supports effective manual soldering and prototyping, advantageous for complex or custom hardware assemblies.

Benefits of SMT Soldering in Modern Electronics

SMT soldering offers significant advantages in modern electronics by enabling higher component density and smaller device footprints, which enhance overall circuit performance. Its automated process improves manufacturing speed and precision, reducing errors and increasing production efficiency. The superior electrical performance and thermal reliability of SMT solder joints contribute to the durability and functionality of advanced electronic devices.

Applications Suited for THT Soldering

THT soldering is ideal for applications requiring strong mechanical bonds, such as heavy or high-stress components like transformers, connectors, and large capacitors. It is widely used in military, aerospace, and automotive industries where durability and reliability are critical under harsh environmental conditions. THT also suits prototypes and repair work due to its easier manual handling compared to SMT soldering.

Common Uses for SMT Soldering in Hardware Design

Surface-Mount Technology (SMT) soldering is widely used in modern hardware design for assembling compact and high-density electronic circuits, making it ideal for smartphones, laptops, and wearable devices. SMT components are typically smaller and allow for automated placement, enhancing production efficiency and reducing manufacturing costs. This soldering method is essential for applications requiring miniaturization and high performance, such as in computer motherboards, automotive electronics, and medical devices.

Reliability and Durability: THT vs. SMT Soldering

THT soldering offers higher mechanical strength and robust connections due to through-hole leads permanently securing components to the PCB, enhancing durability in high-stress environments. SMT soldering provides increased reliability in high-density circuits with finer pitch components, although its surface mounting is more susceptible to mechanical fatigue under extreme vibration. Choosing between THT and SMT soldering depends on application-specific requirements for longevity and environmental resistance.

Cost Considerations: THT versus SMT Soldering

Through-Hole Technology (THT) soldering generally incurs higher labor and material costs due to manual assembly and the use of more robust components, making it less cost-effective for high-volume production. Surface-Mount Technology (SMT) soldering offers reduced production costs by enabling automated assembly, smaller component sizes, and higher component density on PCBs. Cost efficiency in SMT is further enhanced by faster processing times and lower material usage, positioning it as the preferred method for large-scale manufacturing.

Challenges and Limitations of Each Soldering Method

Through-hole technology (THT) soldering faces challenges such as limited component density and labor-intensive manual placement, which can lead to higher manufacturing costs and slower production times. Surface-mount technology (SMT) soldering requires precise control of solder paste application and reflow profiles, making it susceptible to defects like tombstoning and solder bridging. Both methods encounter limitations in thermal management and mechanical reliability, with THT providing stronger mechanical bonds but slower processing, while SMT offers high-speed automation but demands stringent quality control.

Choosing Between THT and SMT Soldering for Your Project

Choosing between THT (Through-Hole Technology) and SMT (Surface-Mount Technology) soldering depends on factors like component size, board complexity, and mechanical strength requirements. THT soldering offers stronger mechanical bonds ideal for heavy or high-stress components, while SMT soldering provides higher component density and better suitability for automated mass production. Project specifications, including reliability and space constraints, ultimately guide the decision for optimal soldering technology.

THT Soldering vs SMT Soldering Infographic

productdif.com

productdif.com