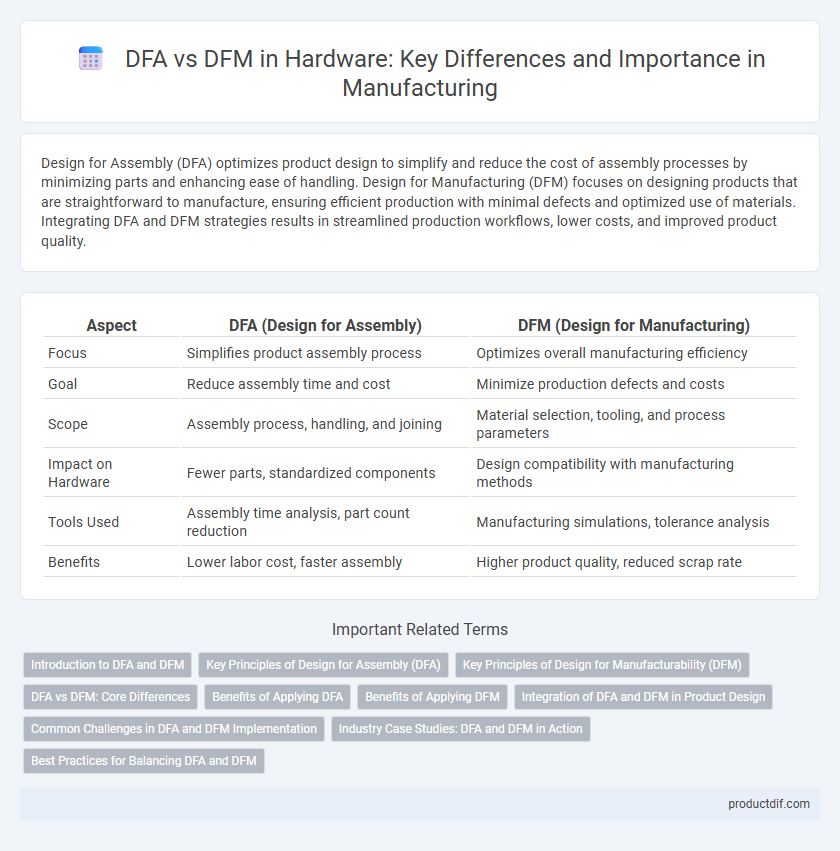

Design for Assembly (DFA) optimizes product design to simplify and reduce the cost of assembly processes by minimizing parts and enhancing ease of handling. Design for Manufacturing (DFM) focuses on designing products that are straightforward to manufacture, ensuring efficient production with minimal defects and optimized use of materials. Integrating DFA and DFM strategies results in streamlined production workflows, lower costs, and improved product quality.

Table of Comparison

| Aspect | DFA (Design for Assembly) | DFM (Design for Manufacturing) |

|---|---|---|

| Focus | Simplifies product assembly process | Optimizes overall manufacturing efficiency |

| Goal | Reduce assembly time and cost | Minimize production defects and costs |

| Scope | Assembly process, handling, and joining | Material selection, tooling, and process parameters |

| Impact on Hardware | Fewer parts, standardized components | Design compatibility with manufacturing methods |

| Tools Used | Assembly time analysis, part count reduction | Manufacturing simulations, tolerance analysis |

| Benefits | Lower labor cost, faster assembly | Higher product quality, reduced scrap rate |

Introduction to DFA and DFM

Design for Assembly (DFA) streamlines product assembly by minimizing part count and simplifying component interactions, reducing manufacturing time and cost. Design for Manufacturability (DFM) ensures that product designs accommodate efficient, cost-effective manufacturing processes by addressing material selection, tooling, and process capabilities. Both DFA and DFM integrate early in the product development cycle to enhance overall production efficiency and product quality.

Key Principles of Design for Assembly (DFA)

Design for Assembly (DFA) emphasizes reducing the number of parts to simplify assembly processes, thereby lowering production costs and time. Key principles include minimizing the variety of fasteners, designing parts for easy handling and orientation, and ensuring that assembly operations require minimal force and motion. Applying these guidelines enhances manufacturability, improves product reliability, and streamlines automated or manual assembly lines.

Key Principles of Design for Manufacturability (DFM)

Design for Manufacturability (DFM) emphasizes optimizing product designs to simplify manufacturing processes, reduce costs, and improve yield rates. Key principles include standardization of components, minimizing part count, and ensuring ease of assembly and testing to enhance production efficiency. Implementing DFM early in the design phase helps identify potential manufacturing challenges, enabling proactive adjustments that prevent delays and defects.

DFA vs DFM: Core Differences

DFA (Design for Assembly) emphasizes minimizing the number of parts and simplifying product assembly to reduce manufacturing costs and assembly time. DFM (Design for Manufacturing) focuses on optimizing the entire manufacturing process, including material selection, machining, and fabrication methods, to enhance product quality and production efficiency. The core difference lies in DFA targeting ease of assembly specifically, while DFM encompasses a broader scope of manufacturing considerations to improve overall product manufacturability.

Benefits of Applying DFA

Applying Design for Assembly (DFA) techniques streamlines the manufacturing process by reducing the number of components and simplifying product structure, leading to lower assembly costs and faster production times. DFA enhances product quality by minimizing assembly errors and improving reliability through straightforward assembly steps. This approach also supports efficient resource utilization and easier automation, driving overall operational efficiency in hardware development.

Benefits of Applying DFM

Applying Design for Manufacturability (DFM) techniques significantly enhances production yield by minimizing errors during manufacturing, reducing costs associated with rework and scrap. It streamlines the transition from design to fabrication, ensuring compatibility with existing manufacturing processes and materials. This approach leads to faster time-to-market and improved product reliability through optimized design constraints aligned with manufacturing capabilities.

Integration of DFA and DFM in Product Design

Integration of Design for Assembly (DFA) and Design for Manufacturing (DFM) significantly enhances product design by streamlining both assembly processes and manufacturing operations, reducing time-to-market and production costs. Combining DFA and DFM principles enables engineers to optimize component shapes, materials, and tolerances, which improves overall product quality and simplifies supply chain logistics. Applying integrated DFA/DFM strategies in CAD software facilitates early detection of design issues, ensuring manufacturability and assembly efficiency from the initial design phase.

Common Challenges in DFA and DFM Implementation

Common challenges in DFA (Design for Assembly) and DFM (Design for Manufacturing) implementation include balancing product complexity with ease of assembly and manufacturing efficiency. Ensuring compatibility between design requirements and manufacturing processes often involves overcoming material limitations and equipment constraints. Addressing these issues requires careful integration of cross-functional teams, advanced simulation tools, and iterative design adjustments to minimize production costs and improve product quality.

Industry Case Studies: DFA and DFM in Action

Industry case studies highlight how Design for Assembly (DFA) reduces manufacturing costs by minimizing part counts and simplifying assembly processes, exemplified by automotive manufacturers streamlining engine components to enhance productivity. Design for Manufacturing (DFM) focuses on optimizing product designs for fabrication efficiency, as seen in consumer electronics companies using DFM principles to improve material usage and machining times. Combining DFA and DFM strategies enables industries to achieve higher product quality and faster time-to-market through integrated design and production workflows.

Best Practices for Balancing DFA and DFM

Balancing Design for Assembly (DFA) and Design for Manufacturing (DFM) involves integrating component simplicity with process efficiency to reduce production costs and improve product quality. Utilizing modular designs and standardizing parts can streamline assembly while ensuring manufacturability across various production methods. Employing concurrent engineering practices and leveraging CAD simulations enables identification of potential assembly issues and manufacturing constraints early in the design phase.

DFA vs DFM Infographic

productdif.com

productdif.com