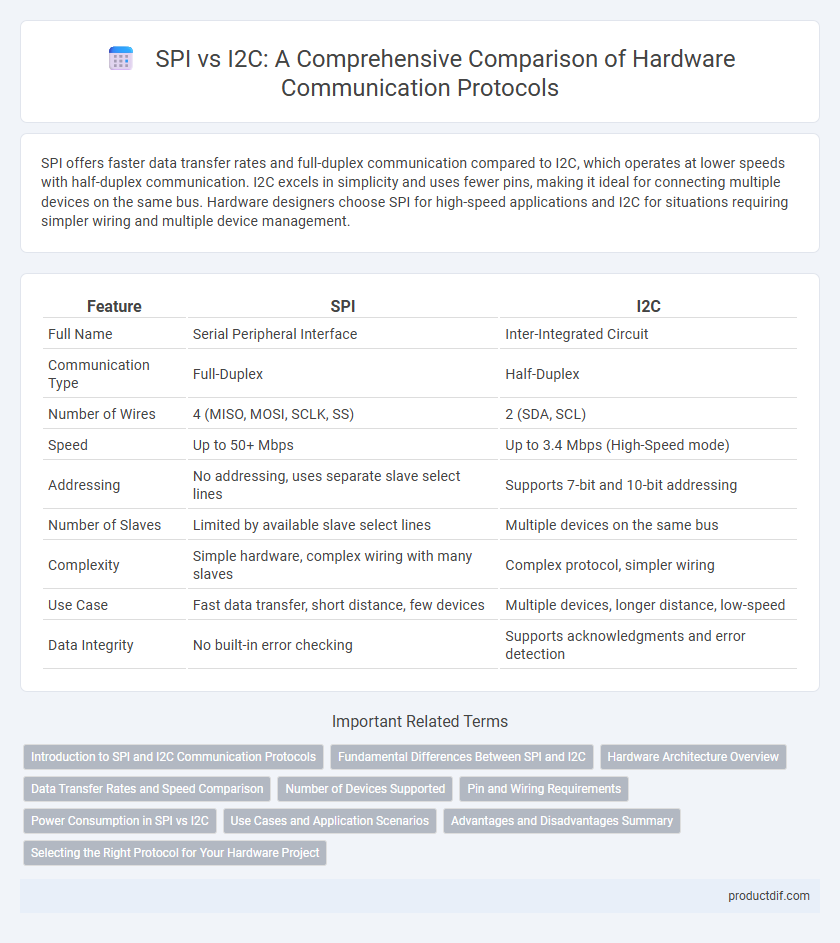

SPI offers faster data transfer rates and full-duplex communication compared to I2C, which operates at lower speeds with half-duplex communication. I2C excels in simplicity and uses fewer pins, making it ideal for connecting multiple devices on the same bus. Hardware designers choose SPI for high-speed applications and I2C for situations requiring simpler wiring and multiple device management.

Table of Comparison

| Feature | SPI | I2C |

|---|---|---|

| Full Name | Serial Peripheral Interface | Inter-Integrated Circuit |

| Communication Type | Full-Duplex | Half-Duplex |

| Number of Wires | 4 (MISO, MOSI, SCLK, SS) | 2 (SDA, SCL) |

| Speed | Up to 50+ Mbps | Up to 3.4 Mbps (High-Speed mode) |

| Addressing | No addressing, uses separate slave select lines | Supports 7-bit and 10-bit addressing |

| Number of Slaves | Limited by available slave select lines | Multiple devices on the same bus |

| Complexity | Simple hardware, complex wiring with many slaves | Complex protocol, simpler wiring |

| Use Case | Fast data transfer, short distance, few devices | Multiple devices, longer distance, low-speed |

| Data Integrity | No built-in error checking | Supports acknowledgments and error detection |

Introduction to SPI and I2C Communication Protocols

SPI (Serial Peripheral Interface) and I2C (Inter-Integrated Circuit) are widely used communication protocols in embedded systems for connecting microcontrollers to peripheral devices. SPI uses a full-duplex, four-wire interface that includes MOSI, MISO, SCLK, and SS lines, enabling high-speed data transfer with straightforward hardware implementation. In contrast, I2C employs a two-wire bidirectional bus with SDA and SCL lines, supporting multi-master and multi-slave configurations with built-in addressing and simple wiring, making it ideal for short-distance, low-speed communication.

Fundamental Differences Between SPI and I2C

SPI (Serial Peripheral Interface) operates with separate data lines for sending and receiving, enabling full-duplex communication, while I2C (Inter-Integrated Circuit) uses a two-wire, half-duplex bus with shared data and clock lines. SPI requires dedicated chip select lines for each device, supporting higher data transfer rates, whereas I2C uses unique addresses on a single bus, allowing multiple devices with fewer pins. The fundamental difference lies in SPI's speed and simplicity versus I2C's multi-device communication and reduced wiring complexity.

Hardware Architecture Overview

SPI employs a master-slave architecture with separate lines for data (MOSI, MISO), clock (SCLK), and chip select (CS), enabling full-duplex communication and high-speed data transfer. I2C uses a two-wire interface consisting of serial data (SDA) and serial clock (SCL) shared among multiple devices, supporting multi-master and multi-slave configurations with built-in addressing. The hardware simplicity of I2C reduces pin count but limits speed, whereas SPI requires more pins but allows faster and more flexible data exchange.

Data Transfer Rates and Speed Comparison

SPI (Serial Peripheral Interface) supports significantly higher data transfer rates than I2C (Inter-Integrated Circuit), often reaching speeds up to tens of Mbps compared to I2C's maximum of 3.4 Mbps in high-speed mode. SPI achieves faster communication by using separate lines for data and clock, enabling full-duplex transmission without the overhead of addressing or arbitration present in I2C protocols. For applications requiring rapid data exchange and low latency, SPI is preferred over I2C due to its superior speed and efficient bus utilization.

Number of Devices Supported

SPI supports multiple devices through dedicated chip select lines, allowing for a theoretically large number of peripheral connections limited primarily by available GPIO pins. I2C, using a shared two-wire bus with unique 7-bit or 10-bit addresses, can support up to 127 devices on the same bus segment without additional hardware. The scalability of I2C is constrained by address conflicts and bus capacitance, whereas SPI offers more flexible device expansion at the cost of increased wiring complexity.

Pin and Wiring Requirements

SPI requires four dedicated pins: MOSI, MISO, SCLK, and SS, enabling full-duplex communication and faster data transfer rates. I2C uses only two wires, SDA and SCL, allowing multiple devices to share the same bus with simpler wiring but generally slower speeds. The distinct pin and wiring requirements impact design complexity, with SPI's pin-intensive setup versus I2C's minimal connection scheme.

Power Consumption in SPI vs I2C

SPI generally consumes more power than I2C due to its continuous clock signal and multiple data lines requiring constant switching. I2C operates at lower power levels by using open-drain lines with pull-up resistors, allowing devices to share a single data line and reducing overall switching activity. In low-power applications, I2C's simpler wiring and efficient bus arbitration make it more suitable than SPI for minimizing energy consumption.

Use Cases and Application Scenarios

SPI offers high-speed communication suitable for applications requiring rapid data transfer such as sensors, flash memory, and display modules, commonly found in embedded systems and consumer electronics. I2C excels in connecting multiple peripherals like EEPROMs, RTCs, and ADCs on a single bus, ideal for complex systems needing efficient multi-device communication with fewer pins. Industrial automation and wearable devices often leverage I2C for its simplicity and scalability, while SPI is preferred in scenarios demanding full-duplex communication and low latency.

Advantages and Disadvantages Summary

SPI offers faster data transfer rates, full-duplex communication, and simpler hardware implementation, making it ideal for high-speed applications; however, it requires more pins and lacks built-in addressing. I2C uses fewer pins with two-wire communication and supports multiple devices through addressing, which simplifies wiring and scalability but suffers from slower speeds and potential bus contention issues. Choosing between SPI and I2C depends on the priorities of speed, complexity, and the number of devices in the hardware design.

Selecting the Right Protocol for Your Hardware Project

Selecting the right protocol between SPI and I2C depends on specific hardware project requirements such as data transfer speed, complexity, and the number of devices connected. SPI offers faster data rates up to several MHz and supports full-duplex communication, making it ideal for applications requiring high-speed data exchange between microcontrollers and peripherals. I2C provides a simpler two-wire interface with built-in addressing, suitable for systems with multiple devices on the same bus and moderate speed requirements.

SPI vs I2C Infographic

productdif.com

productdif.com