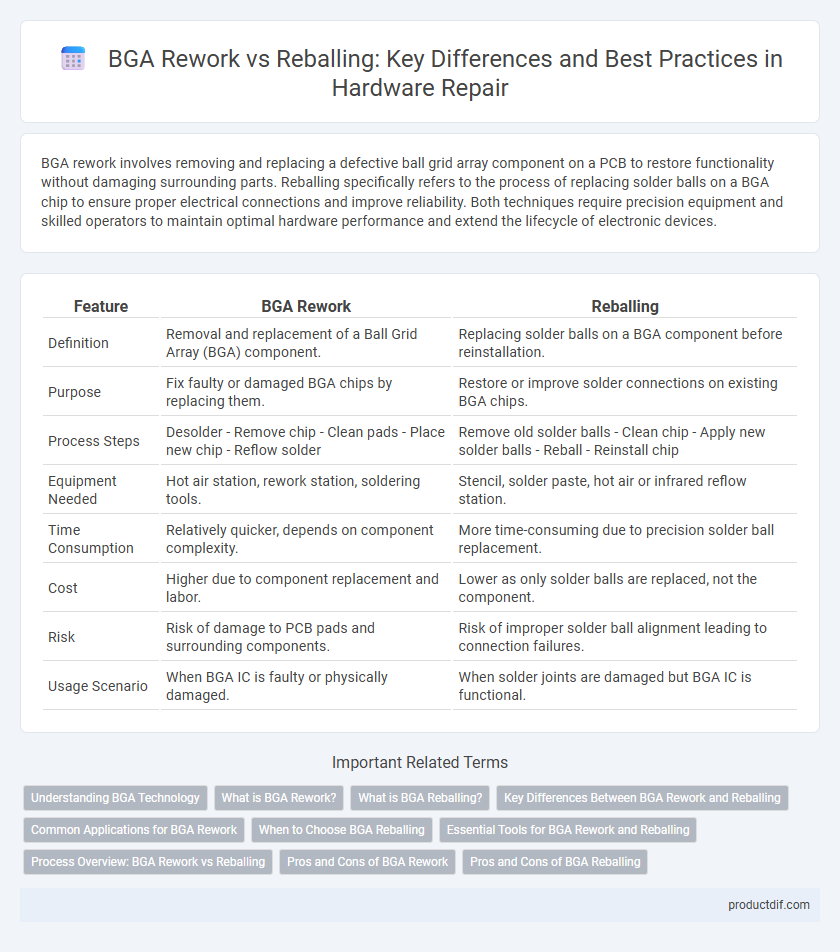

BGA rework involves removing and replacing a defective ball grid array component on a PCB to restore functionality without damaging surrounding parts. Reballing specifically refers to the process of replacing solder balls on a BGA chip to ensure proper electrical connections and improve reliability. Both techniques require precision equipment and skilled operators to maintain optimal hardware performance and extend the lifecycle of electronic devices.

Table of Comparison

| Feature | BGA Rework | Reballing |

|---|---|---|

| Definition | Removal and replacement of a Ball Grid Array (BGA) component. | Replacing solder balls on a BGA component before reinstallation. |

| Purpose | Fix faulty or damaged BGA chips by replacing them. | Restore or improve solder connections on existing BGA chips. |

| Process Steps | Desolder - Remove chip - Clean pads - Place new chip - Reflow solder | Remove old solder balls - Clean chip - Apply new solder balls - Reball - Reinstall chip |

| Equipment Needed | Hot air station, rework station, soldering tools. | Stencil, solder paste, hot air or infrared reflow station. |

| Time Consumption | Relatively quicker, depends on component complexity. | More time-consuming due to precision solder ball replacement. |

| Cost | Higher due to component replacement and labor. | Lower as only solder balls are replaced, not the component. |

| Risk | Risk of damage to PCB pads and surrounding components. | Risk of improper solder ball alignment leading to connection failures. |

| Usage Scenario | When BGA IC is faulty or physically damaged. | When solder joints are damaged but BGA IC is functional. |

Understanding BGA Technology

Ball Grid Array (BGA) technology involves mounting integrated circuits using solder balls arranged in a grid on the underside of the package, enabling high-density connections and improved electrical performance. BGA rework focuses on replacing or repairing defective chips without altering the solder ball configuration, preserving the original layout. Reballing, a more intensive process, involves removing old solder balls and applying new ones to restore reliable connections and extend the lifespan of the BGA component.

What is BGA Rework?

BGA rework refers to the precise process of repairing or replacing a Ball Grid Array (BGA) component on a printed circuit board (PCB) by removing the faulty chip and resoldering a new one. This technique involves specialized equipment to carefully heat, lift, and realign the BGA package without damaging the PCB or surrounding components. BGA rework is crucial for fixing solder joint defects, improving device reliability, and extending the lifespan of electronic hardware.

What is BGA Reballing?

BGA reballing is a hardware repair process that involves removing the Ball Grid Array (BGA) component from a circuit board, cleaning off the old solder balls, and replacing them with new solder balls to restore proper electrical connections. This technique is essential for fixing faulty or damaged solder joints on BGAs, which are commonly used in advanced electronic devices like smartphones, laptops, and gaming consoles. Reballing improves device reliability and functionality by ensuring secure and consistent contact between the BGA and the PCB.

Key Differences Between BGA Rework and Reballing

BGA rework involves removing a defective Ball Grid Array component from a PCB and replacing it with a new or tested unit, ensuring proper alignment and solder joint quality. Reballing specifically refers to replacing the solder balls on the BGA package itself, which restores the integrity of the solder connections without changing the component. Key differences include the scope of repair--rework addresses the entire component and board interface, while reballing focuses solely on refurbishing the solder balls of the BGA component.

Common Applications for BGA Rework

BGA rework is commonly applied in repairing defective solder joints on printed circuit boards (PCBs) to restore electrical connectivity without replacing the entire component. It is widely used in the semiconductor manufacturing industry for fixing issues in integrated circuits, GPUs, and memory modules. This process helps to extend the lifespan of electronic devices by addressing soldering defects caused by thermal stress or mechanical damage.

When to Choose BGA Reballing

BGA reballing is the preferred choice when the solder balls on a Ball Grid Array (BGA) package are damaged, missing, or contaminated, impairing proper electrical connections. It is essential for restoring the integrity of the solder joints to ensure reliable signal transmission and mechanical stability. Reballing becomes necessary after multiple rework attempts or when the original solder balls are compromised beyond simple cleaning or reheating.

Essential Tools for BGA Rework and Reballing

Essential tools for BGA rework include a hot air rework station, precision tweezers, thermal imaging camera, and flux dispensers to ensure precise heat application and component handling. For BGA reballing, specialized stencil kits for solder paste application, a reflow oven, solder balls, and a microscope for detailed inspection are critical for successful pad restoration and ball placement. Both processes demand a high level of accuracy, making the investment in quality tools vital for effective BGA repair and assembly.

Process Overview: BGA Rework vs Reballing

BGA rework involves precise removal and replacement of a Ball Grid Array component to fix defects or upgrade parts without disturbing the PCB. Reballing is the process of cleaning off old solder balls from the BGA and applying new solder spheres to restore proper connections and improve reliability. Both processes require specialized equipment such as hot air rework stations and solder ball placement tools to ensure precise temperature control and alignment.

Pros and Cons of BGA Rework

BGA rework offers precise repair of defective solder joints on ball grid arrays, minimizing the need for complete component replacement and reducing overall repair costs. However, the process requires specialized equipment and skilled technicians to avoid damaging sensitive components, which can increase turnaround time and labor expenses. Despite these challenges, successful rework improves device reliability by restoring proper electrical connections without altering board integrity.

Pros and Cons of BGA Reballing

BGA reballing offers a cost-effective solution for repairing damaged ball grid arrays by replacing solder balls, which extends the lifespan of components and reduces the need for full replacements. This process ensures precise solder ball placement and improves electrical connectivity, enhancing device reliability and performance. However, BGA reballing requires specialized equipment and skilled technicians, with risks of thermal damage or misalignment that can compromise the repair quality.

BGA Rework vs Reballing Infographic

productdif.com

productdif.com