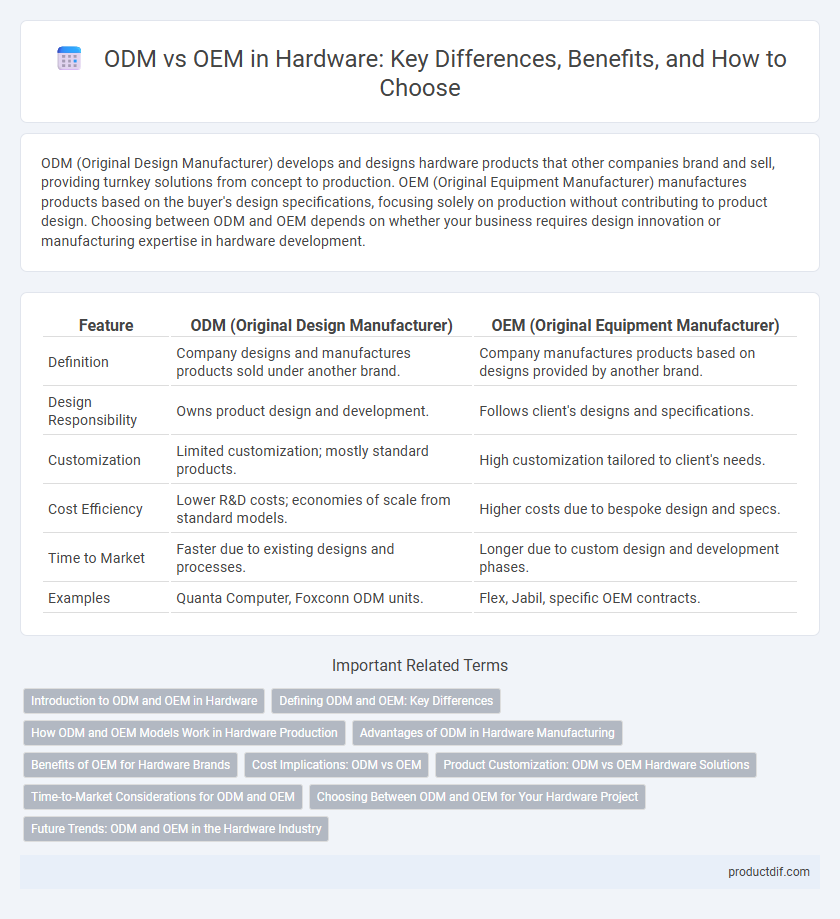

ODM (Original Design Manufacturer) develops and designs hardware products that other companies brand and sell, providing turnkey solutions from concept to production. OEM (Original Equipment Manufacturer) manufactures products based on the buyer's design specifications, focusing solely on production without contributing to product design. Choosing between ODM and OEM depends on whether your business requires design innovation or manufacturing expertise in hardware development.

Table of Comparison

| Feature | ODM (Original Design Manufacturer) | OEM (Original Equipment Manufacturer) |

|---|---|---|

| Definition | Company designs and manufactures products sold under another brand. | Company manufactures products based on designs provided by another brand. |

| Design Responsibility | Owns product design and development. | Follows client's designs and specifications. |

| Customization | Limited customization; mostly standard products. | High customization tailored to client's needs. |

| Cost Efficiency | Lower R&D costs; economies of scale from standard models. | Higher costs due to bespoke design and specs. |

| Time to Market | Faster due to existing designs and processes. | Longer due to custom design and development phases. |

| Examples | Quanta Computer, Foxconn ODM units. | Flex, Jabil, specific OEM contracts. |

Introduction to ODM and OEM in Hardware

Original Design Manufacturer (ODM) and Original Equipment Manufacturer (OEM) are key models in hardware production, each offering distinct roles in the supply chain. ODM companies design and manufacture complete products sold under different brand names, providing end-to-end solutions from concept to final hardware assembly. OEMs produce components or finished products based on specifications provided by client companies, enabling brands to outsource manufacturing while maintaining design control.

Defining ODM and OEM: Key Differences

ODM (Original Design Manufacturer) develops and designs products which are then branded and sold by another company, whereas OEM (Original Equipment Manufacturer) produces components or products based strictly on the buyer's specifications and design. ODMs handle the entire product creation process from concept to manufacturing, offering turnkey solutions, while OEMs focus on manufacturing specific parts or assemblies to be integrated into the buyer's final product. Key differences lie in design ownership and product customization, with ODMs providing design innovation and OEMs emphasizing manufacturing precision and adherence to client specifications.

How ODM and OEM Models Work in Hardware Production

ODM (Original Design Manufacturer) produces complete hardware products based on their own designs, which companies can brand and sell as their own, streamlining development and reducing time-to-market. OEM (Original Equipment Manufacturer) specializes in manufacturing hardware components or products according to the buyer's specifications and designs, providing customization and control over final product features. Both models enable efficient hardware production but differ in design responsibility and customization flexibility.

Advantages of ODM in Hardware Manufacturing

ODM in hardware manufacturing offers significant advantages including faster time-to-market due to ready-designed products and reduced development costs by leveraging the manufacturer's expertise in design and engineering. ODMs enable companies to customize existing platforms without investing in original product development, streamlining production and enhancing scalability. This approach also allows for greater innovation flexibility, as ODMs continuously improve designs to keep up with technological advancements and market demands.

Benefits of OEM for Hardware Brands

OEM partnerships provide hardware brands with substantial benefits including access to expert manufacturing capabilities, enabling rapid product development and scale without heavy capital investment. This collaboration ensures high-quality production standards and customization options tailored to the brand's specifications, enhancing market competitiveness. OEMs also facilitate streamlined supply chain management, reducing lead times and operational complexities for hardware brands.

Cost Implications: ODM vs OEM

ODM manufacturing typically reduces overall production costs by providing turnkey solutions that include design, prototyping, and manufacturing, allowing companies to avoid investing in product development infrastructure. OEM partnerships often involve higher expenses due to the need for custom designs and specifications, increasing R&D and tooling costs. Choosing ODM can lead to faster market entry and lower upfront investment, while OEM may result in higher cost variability depending on the complexity of the bespoke hardware requirements.

Product Customization: ODM vs OEM Hardware Solutions

ODM hardware solutions offer extensive product customization by designing and manufacturing devices based on clients' specifications, enabling unique features and branding tailored to market needs. OEM hardware provides customization primarily through component integration and minor modifications within an established product framework, focusing on replicating existing designs with client-specific branding. Choosing between ODM and OEM depends on the desired level of product differentiation and control over the hardware development process.

Time-to-Market Considerations for ODM and OEM

ODM (Original Design Manufacturer) offers faster time-to-market due to ready-made designs and streamlined production processes, allowing companies to launch products quickly without extensive development phases. OEM (Original Equipment Manufacturer) requires longer lead times as products are custom-designed and tailored to specific client specifications, involving detailed design, prototyping, and testing stages. Choosing ODM accelerates market entry with reduced R&D investment, while OEM prioritizes customization at the expense of extended development timelines.

Choosing Between ODM and OEM for Your Hardware Project

Choosing between ODM and OEM for your hardware project depends on your desired level of customization and control. ODMs provide ready-made designs with faster time-to-market and reduced development costs, ideal for companies seeking standardized solutions. OEMs offer greater customization and brand exclusivity by manufacturing products based on your design specifications, suitable for businesses prioritizing unique hardware features and differentiation.

Future Trends: ODM and OEM in the Hardware Industry

Future trends in the hardware industry indicate a growing integration of ODM and OEM models to enhance customization and speed to market. Advances in smart manufacturing and AI-driven design are enabling ODMs to offer more tailored solutions while OEMs focus on brand differentiation and quality control. Collaboration between ODMs and OEMs is expected to drive innovation in IoT devices, wearables, and edge computing hardware.

ODM vs OEM Infographic

productdif.com

productdif.com