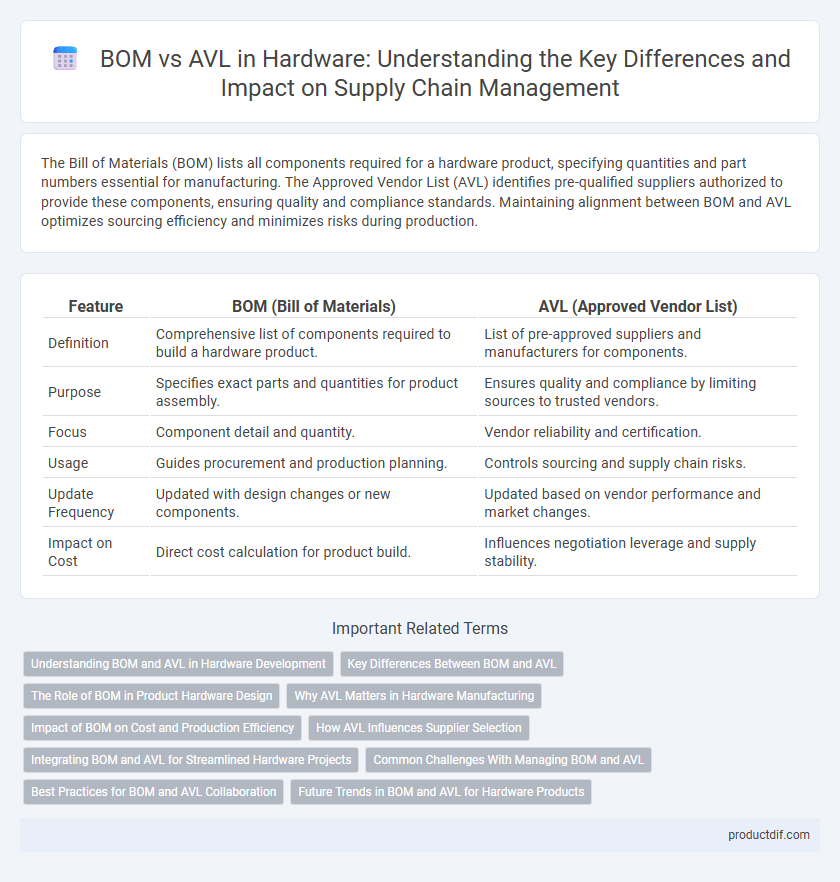

The Bill of Materials (BOM) lists all components required for a hardware product, specifying quantities and part numbers essential for manufacturing. The Approved Vendor List (AVL) identifies pre-qualified suppliers authorized to provide these components, ensuring quality and compliance standards. Maintaining alignment between BOM and AVL optimizes sourcing efficiency and minimizes risks during production.

Table of Comparison

| Feature | BOM (Bill of Materials) | AVL (Approved Vendor List) |

|---|---|---|

| Definition | Comprehensive list of components required to build a hardware product. | List of pre-approved suppliers and manufacturers for components. |

| Purpose | Specifies exact parts and quantities for product assembly. | Ensures quality and compliance by limiting sources to trusted vendors. |

| Focus | Component detail and quantity. | Vendor reliability and certification. |

| Usage | Guides procurement and production planning. | Controls sourcing and supply chain risks. |

| Update Frequency | Updated with design changes or new components. | Updated based on vendor performance and market changes. |

| Impact on Cost | Direct cost calculation for product build. | Influences negotiation leverage and supply stability. |

Understanding BOM and AVL in Hardware Development

A Bill of Materials (BOM) in hardware development outlines all the components, quantities, and specifications required for manufacturing a product, serving as a definitive parts list. An Approved Vendor List (AVL) specifies verified and authorized suppliers for components within the BOM, ensuring quality, availability, and compliance with design requirements. Effective coordination between BOM and AVL streamlines sourcing, reduces risks of component obsolescence, and maintains supply chain reliability during product lifecycle management.

Key Differences Between BOM and AVL

The Bill of Materials (BOM) lists all components and raw materials required to manufacture a product, specifying quantities and part numbers. The Approved Vendor List (AVL) identifies suppliers authorized to provide those components, ensuring compliance with quality and sourcing standards. While BOM defines what is needed for production, AVL controls where those components can be sourced, impacting supply chain management and inventory control.

The Role of BOM in Product Hardware Design

The Bill of Materials (BOM) plays a critical role in product hardware design by providing a detailed list of components required for manufacturing, enabling precise cost estimation and resource planning. It ensures accurate communication between design engineers and procurement teams, facilitating efficient sourcing and inventory management. The BOM serves as the foundation for tracking version control and product lifecycle, directly impacting product quality and time-to-market.

Why AVL Matters in Hardware Manufacturing

The Approved Vendor List (AVL) is critical in hardware manufacturing because it ensures component quality, reliability, and supply chain consistency by limiting procurement to pre-qualified suppliers. While the Bill of Materials (BOM) specifies the components required, the AVL guarantees those components meet stringent performance standards and compliance requirements, reducing risks of counterfeit or substandard parts. Maintaining an up-to-date AVL streamlines production, minimizes delays, and supports cost-effective sourcing strategies essential for robust hardware development.

Impact of BOM on Cost and Production Efficiency

A Bill of Materials (BOM) directly influences manufacturing costs by detailing the exact quantity and specifications of components required, enabling precise budgeting and minimizing excess inventory. Effective BOM management reduces production delays and errors, enhancing overall manufacturing efficiency and product quality. Integrating BOM with supplier data ensures streamlined procurement, further lowering costs and optimizing production timelines.

How AVL Influences Supplier Selection

The Approved Vendor List (AVL) directly affects supplier selection by defining pre-qualified manufacturers whose components meet specific standards for quality, cost, and availability. This ensures procurement teams prioritize suppliers that have undergone rigorous evaluation, reducing risks related to component reliability and supply chain disruptions. Integrating the AVL with the Bill of Materials (BOM) streamlines sourcing by linking approved parts to precise project requirements, enhancing overall hardware production efficiency.

Integrating BOM and AVL for Streamlined Hardware Projects

Integrating Bill of Materials (BOM) and Approved Vendor List (AVL) streamlines hardware projects by ensuring component availability and compliance throughout the supply chain. Leveraging BOM-AVL integration reduces lead times and mitigates risks associated with sourcing non-approved parts, enhancing production efficiency. Synchronizing these lists enables accurate cost estimation and simplifies procurement processes, driving consistent project timelines and quality standards.

Common Challenges With Managing BOM and AVL

Managing BOM and AVL often involves challenges like ensuring accuracy and completeness of components across multiple suppliers, which can lead to discrepancies affecting product assembly and cost. Synchronizing updates between BOM and AVL requires constant communication to prevent obsolete or unauthorized parts from entering the production line. Supply chain variability and rapid technology changes further complicate maintaining an up-to-date and compliant BOM and AVL, impacting overall hardware development efficiency.

Best Practices for BOM and AVL Collaboration

Effective collaboration between Bill of Materials (BOM) and Approved Vendor List (AVL) ensures streamlined hardware production by aligning component specifications with qualified supplier data. Best practices include maintaining updated, synchronized databases to avoid component mismatches and supply chain disruptions, and conducting regular cross-functional reviews involving engineering, procurement, and quality teams. Implementing integrated software tools enhances traceability, reduces lead times, and supports compliance with industry standards in hardware manufacturing.

Future Trends in BOM and AVL for Hardware Products

Future trends in Bill of Materials (BOM) and Approved Vendor List (AVL) for hardware products emphasize increased digitization and integration with AI-powered supply chain management systems, enhancing real-time decision-making and risk mitigation. Advanced predictive analytics enable dynamic updates to BOM and AVL, optimizing component selection based on availability, cost fluctuations, and quality metrics. Blockchain technology is also being explored to ensure traceability and authenticity within BOM and AVL processes, improving transparency and trust across hardware manufacturing ecosystems.

BOM vs AVL Infographic

productdif.com

productdif.com