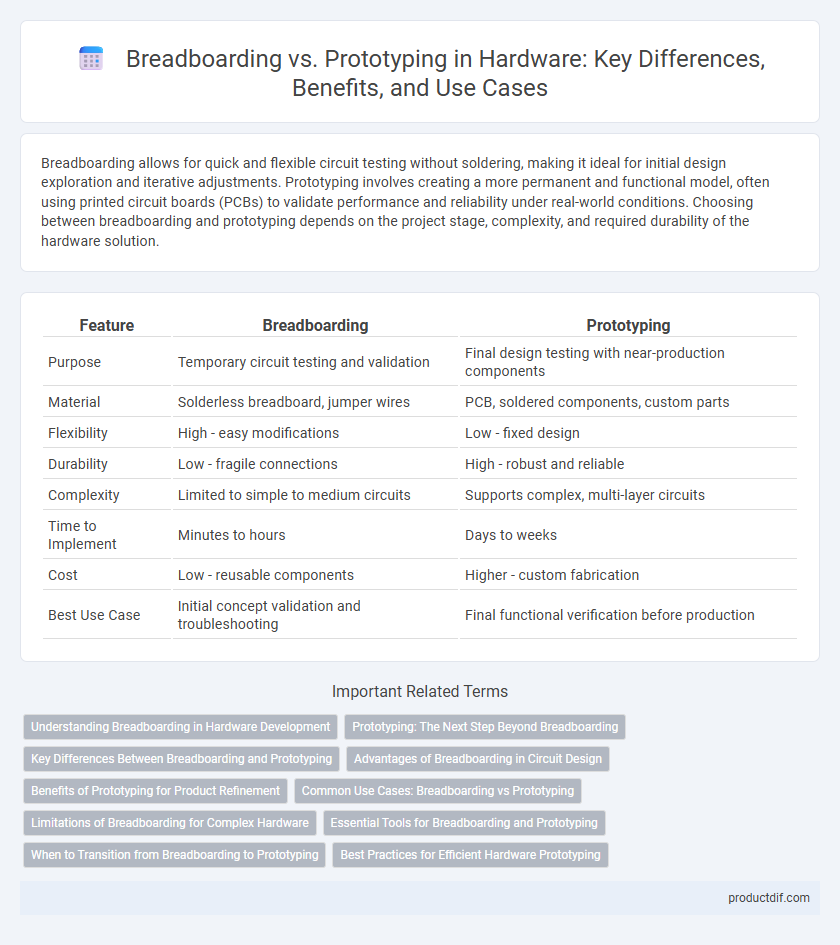

Breadboarding allows for quick and flexible circuit testing without soldering, making it ideal for initial design exploration and iterative adjustments. Prototyping involves creating a more permanent and functional model, often using printed circuit boards (PCBs) to validate performance and reliability under real-world conditions. Choosing between breadboarding and prototyping depends on the project stage, complexity, and required durability of the hardware solution.

Table of Comparison

| Feature | Breadboarding | Prototyping |

|---|---|---|

| Purpose | Temporary circuit testing and validation | Final design testing with near-production components |

| Material | Solderless breadboard, jumper wires | PCB, soldered components, custom parts |

| Flexibility | High - easy modifications | Low - fixed design |

| Durability | Low - fragile connections | High - robust and reliable |

| Complexity | Limited to simple to medium circuits | Supports complex, multi-layer circuits |

| Time to Implement | Minutes to hours | Days to weeks |

| Cost | Low - reusable components | Higher - custom fabrication |

| Best Use Case | Initial concept validation and troubleshooting | Final functional verification before production |

Understanding Breadboarding in Hardware Development

Breadboarding in hardware development allows engineers to create and test circuit designs quickly without soldering, using a reusable board with interconnected metal strips. This method facilitates iterative design, debugging, and component experimentation, streamlining early-stage development and minimizing costly errors. Breadboards support a variety of electronic components, making them essential tools for validating circuit functionality before transitioning to more permanent prototyping solutions.

Prototyping: The Next Step Beyond Breadboarding

Prototyping advances beyond breadboarding by enabling the creation of more refined and functional hardware models that closely mimic the final product's performance and durability. It incorporates custom PCBs, integrated components, and optimized layouts to test real-world usability and electrical reliability under varying conditions. This stage is critical for identifying design flaws, validating circuit functionality, and accelerating the transition from concept to production-ready hardware.

Key Differences Between Breadboarding and Prototyping

Breadboarding involves creating temporary circuits using a solderless board to test component functionality and layout flexibility, ideal for early-stage design validation. Prototyping refers to building a more permanent and refined version of a circuit, often on a printed circuit board (PCB), which allows for comprehensive testing under real-world conditions and integration of final components. The key differences lie in durability, complexity, and suitability for testing phases, with breadboarding offering quick modifications and prototyping providing a near-final product evaluation.

Advantages of Breadboarding in Circuit Design

Breadboarding offers rapid and flexible circuit design without soldering, enabling easy modifications and troubleshooting during development. It supports the testing of complex circuits with reusable components, reducing costs and time compared to traditional prototyping methods. This hands-on approach enhances iterative design and accelerates innovation in hardware projects.

Benefits of Prototyping for Product Refinement

Prototyping offers significant advantages for product refinement by enabling early detection and correction of design flaws, which reduces costly errors during production. It allows for realistic testing of functionality, user experience, and performance under actual operating conditions. This iterative process accelerates development cycles and ensures higher quality and reliability in the final hardware product.

Common Use Cases: Breadboarding vs Prototyping

Breadboarding is commonly used for rapid circuit testing and iterative design adjustments without soldering, ideal for early-stage development and educational purposes. Prototyping involves creating more durable and functional models, often incorporating soldered connections and custom PCBs, suitable for validating design integrity before mass production. Engineers prefer breadboarding for experimentation and prototyping for comprehensive product evaluation and refinement.

Limitations of Breadboarding for Complex Hardware

Breadboarding is limited by its inability to handle high-frequency signals or complex integrated circuits due to parasitic capacitance and inductance. The physical constraints and loose connections can cause signal integrity issues and unreliable performance in advanced hardware designs. Prototyping with custom PCBs provides a more stable and scalable solution for complex system validation and testing.

Essential Tools for Breadboarding and Prototyping

Essential tools for breadboarding include solderless breadboards, jumper wires, resistors, capacitors, LEDs, and basic integrated circuits, which facilitate quick and flexible circuit assembly without permanent connections. Prototyping requires more robust hardware such as microcontrollers, sensor modules, printed circuit boards (PCBs), soldering equipment, and multimeters to test and finalize circuit designs. Both processes benefit from power supplies and oscilloscopes to ensure accurate voltage levels and signal analysis during development.

When to Transition from Breadboarding to Prototyping

Transitioning from breadboarding to prototyping is essential once circuit designs demonstrate consistent functionality and stability on the breadboard. Breadboards are ideal for initial testing and circuit iteration, but prototyping with printed circuit boards (PCBs) provides enhanced durability, reliable connections, and scalability for final products. Moving to prototyping reduces errors caused by loose connections and supports integration with enclosures and external components, marking a critical step toward production-ready hardware.

Best Practices for Efficient Hardware Prototyping

Breadboarding allows rapid circuit testing and modification without soldering, making it ideal for initial design validation and troubleshooting in hardware prototyping. Prototyping with printed circuit boards (PCBs) offers durable connections and accurate representation of the final product, crucial for performance testing and reliability assessments. Combining both methods optimizes development efficiency by leveraging breadboards for quick iterations and PCBs for detailed evaluation and refinement.

Breadboarding vs Prototyping Infographic

productdif.com

productdif.com