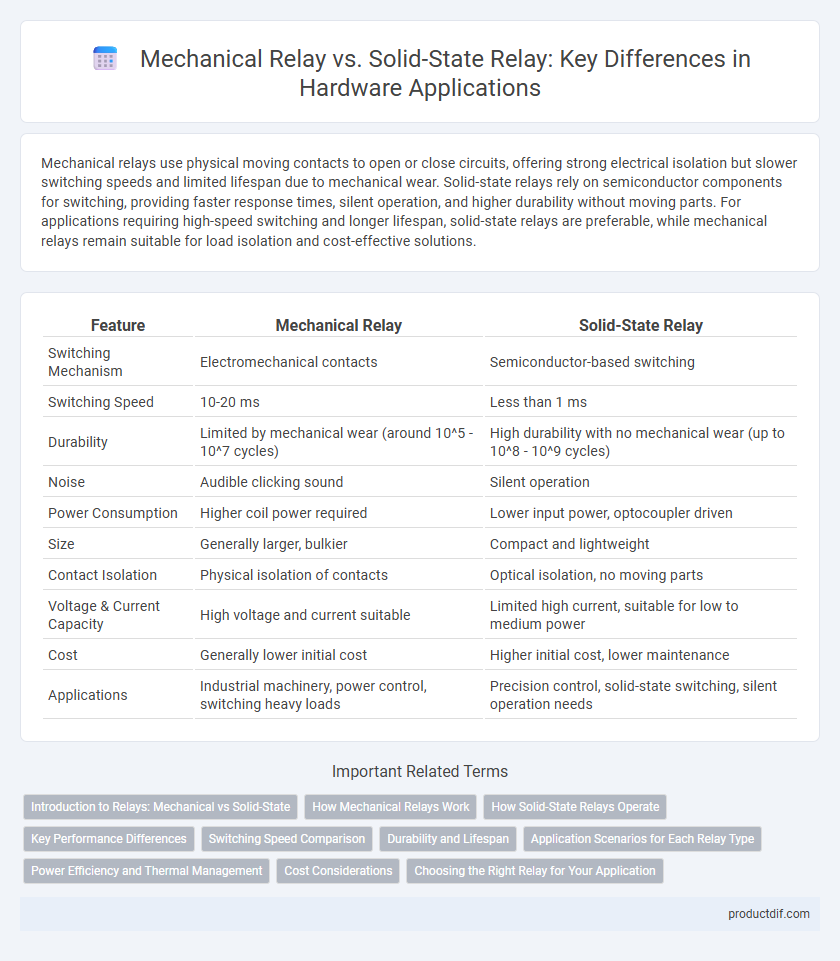

Mechanical relays use physical moving contacts to open or close circuits, offering strong electrical isolation but slower switching speeds and limited lifespan due to mechanical wear. Solid-state relays rely on semiconductor components for switching, providing faster response times, silent operation, and higher durability without moving parts. For applications requiring high-speed switching and longer lifespan, solid-state relays are preferable, while mechanical relays remain suitable for load isolation and cost-effective solutions.

Table of Comparison

| Feature | Mechanical Relay | Solid-State Relay |

|---|---|---|

| Switching Mechanism | Electromechanical contacts | Semiconductor-based switching |

| Switching Speed | 10-20 ms | Less than 1 ms |

| Durability | Limited by mechanical wear (around 10^5 - 10^7 cycles) | High durability with no mechanical wear (up to 10^8 - 10^9 cycles) |

| Noise | Audible clicking sound | Silent operation |

| Power Consumption | Higher coil power required | Lower input power, optocoupler driven |

| Size | Generally larger, bulkier | Compact and lightweight |

| Contact Isolation | Physical isolation of contacts | Optical isolation, no moving parts |

| Voltage & Current Capacity | High voltage and current suitable | Limited high current, suitable for low to medium power |

| Cost | Generally lower initial cost | Higher initial cost, lower maintenance |

| Applications | Industrial machinery, power control, switching heavy loads | Precision control, solid-state switching, silent operation needs |

Introduction to Relays: Mechanical vs Solid-State

Mechanical relays operate using physical contacts to open or close circuits, providing high isolation and reliability in low-frequency applications. Solid-state relays use semiconductor components for switching, offering faster response times, longer lifespan, and silent operation, ideal for high-speed or frequent switching needs. Selecting between mechanical and solid-state relays depends on factors like switching speed, load type, electrical noise, and durability requirements.

How Mechanical Relays Work

Mechanical relays operate through an electromagnetic coil that generates a magnetic field when energized, causing a movable armature to physically open or close electrical contacts. This physical switching mechanism enables isolation between the control circuit and the load, allowing high current flow through the contacts without affecting the control side. Mechanical relays are valued for their ability to handle high voltages and currents, but their mechanical parts can wear out over time due to repeated physical movement.

How Solid-State Relays Operate

Solid-state relays (SSRs) operate by using semiconductor components such as thyristors, triacs, or transistors to switch electrical loads without moving parts. They rely on optoisolators for input-output isolation, enabling control of high-voltage circuits through low-voltage signals with fast switching speeds and reduced noise. Unlike mechanical relays, SSRs provide longer lifespan and greater reliability due to their resistance to physical wear and vibration.

Key Performance Differences

Mechanical relays operate with physical contacts that open and close circuits, resulting in slower switching speeds and limited durability due to contact wear. Solid-state relays use semiconductor components, offering faster switching, longer lifespan, and resistance to mechanical shock and vibration. Key performance differences include response time, with solid-state relays switching in microseconds versus milliseconds for mechanical relays, and current capacity, where mechanical relays typically handle higher voltages but solid-state relays provide greater noise immunity and silent operation.

Switching Speed Comparison

Mechanical relays typically offer switching speeds ranging from 5 to 20 milliseconds due to their physical moving contacts, whereas solid-state relays (SSRs) achieve switching speeds in the microseconds range by utilizing semiconductor components. The absence of mechanical parts in SSRs minimizes wear and enables faster response times, making them ideal for high-frequency switching applications. This significant speed advantage allows solid-state relays to perform more efficiently in circuits requiring rapid and precise switching control.

Durability and Lifespan

Mechanical relays feature physical moving parts prone to wear and tear, resulting in a typical lifespan of around 100,000 to 1 million switching cycles. Solid-state relays, utilizing semiconductor components, offer significantly higher durability with lifespans often exceeding 10 million cycles due to the absence of mechanical movement. The extended operational life and resistance to mechanical fatigue make solid-state relays more reliable in high-cycle or harsh environmental applications.

Application Scenarios for Each Relay Type

Mechanical relays are ideal for applications requiring high current switching and electrical isolation, such as industrial machinery, automotive systems, and heavy-duty equipment due to their robustness and ability to handle inductive loads. Solid-state relays excel in scenarios demanding silent operation, high switching speed, and long lifespan, making them suitable for precision electronic devices, temperature control in HVAC systems, and automated manufacturing processes. Each relay type's unique attributes drive their selection based on load type, switching frequency, and environmental conditions.

Power Efficiency and Thermal Management

Mechanical relays typically consume more power due to coil activation and generate significant heat during operation, impacting overall efficiency and requiring robust thermal management solutions. Solid-state relays (SSRs) offer superior power efficiency by using semiconductor switching elements, resulting in minimal heat generation and reduced cooling requirements. SSRs' low thermal dissipation enhances reliability in power-sensitive and high-frequency switching applications, making them ideal for efficient energy management.

Cost Considerations

Mechanical relays generally have a lower initial cost compared to solid-state relays, making them more budget-friendly for simple switching applications. Solid-state relays, however, offer longer operational life and reduced maintenance costs due to the absence of moving parts, which can offset their higher upfront price over time. When evaluating total cost of ownership, factors such as switching frequency, load type, and lifespan significantly influence the cost-effectiveness of each relay type.

Choosing the Right Relay for Your Application

Mechanical relays offer robust electrical isolation and are ideal for applications requiring high current switching with audible feedback but have slower switching speeds and limited lifespan due to mechanical wear. Solid-state relays provide faster switching, longer durability, and silent operation with no moving parts, making them suitable for high-speed applications and environments sensitive to noise or vibration. Selecting the right relay depends on factors such as load type, switching frequency, environmental conditions, and required electrical isolation.

Mechanical relay vs Solid-state relay Infographic

productdif.com

productdif.com