BGA rework involves precise handling of solder balls beneath the package, requiring specialized equipment for accurate heat application and alignment. QFP rework typically requires careful desoldering of numerous fine-pitch leads around the component perimeter, making it labor-intensive and prone to damage if not performed skillfully. Both processes demand distinct techniques, with BGA rework emphasizing thermal control and alignment accuracy, while QFP rework focuses on lead integrity and thorough cleaning of solder residues.

Table of Comparison

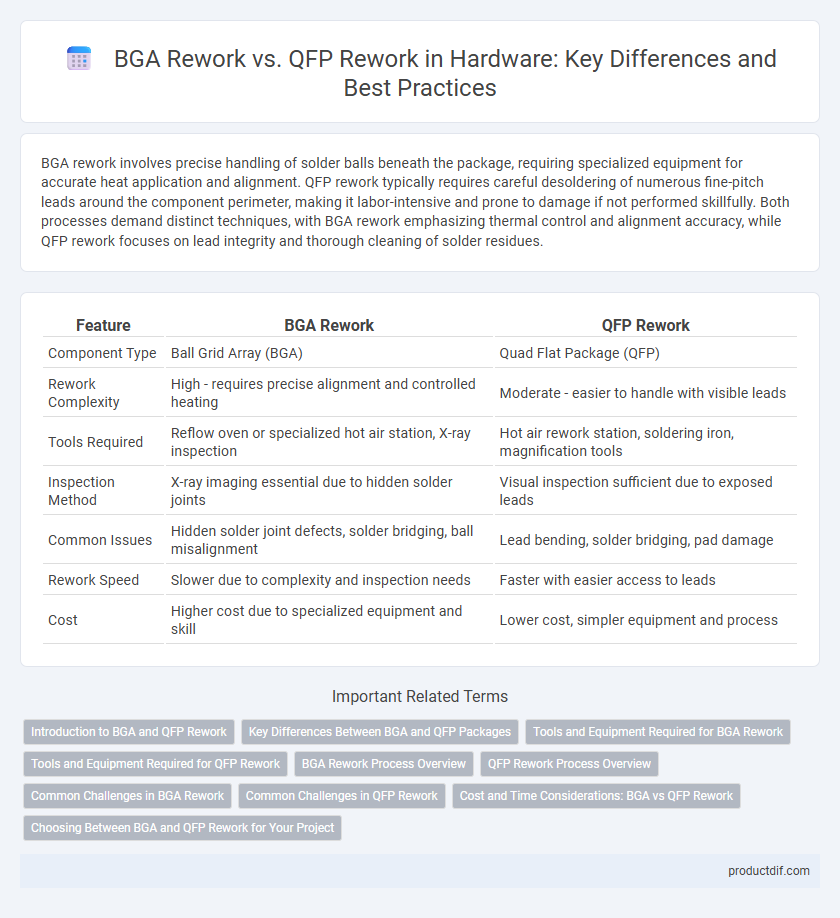

| Feature | BGA Rework | QFP Rework |

|---|---|---|

| Component Type | Ball Grid Array (BGA) | Quad Flat Package (QFP) |

| Rework Complexity | High - requires precise alignment and controlled heating | Moderate - easier to handle with visible leads |

| Tools Required | Reflow oven or specialized hot air station, X-ray inspection | Hot air rework station, soldering iron, magnification tools |

| Inspection Method | X-ray imaging essential due to hidden solder joints | Visual inspection sufficient due to exposed leads |

| Common Issues | Hidden solder joint defects, solder bridging, ball misalignment | Lead bending, solder bridging, pad damage |

| Rework Speed | Slower due to complexity and inspection needs | Faster with easier access to leads |

| Cost | Higher cost due to specialized equipment and skill | Lower cost, simpler equipment and process |

Introduction to BGA and QFP Rework

BGA (Ball Grid Array) rework involves the precise removal and replacement of components with solder balls arranged in a grid pattern on the underside, requiring specialized equipment to ensure proper alignment and solder joint integrity. QFP (Quad Flat Package) rework focuses on handling flat, rectangular chips with leads extending from all four sides, demanding careful heat management and lead alignment to prevent damage. Both BGA and QFP rework are critical for repairing or upgrading electronic assemblies in hardware manufacturing and maintenance.

Key Differences Between BGA and QFP Packages

BGA (Ball Grid Array) rework involves removing and soldering packages with solder balls on the underside, enabling higher pin density and improved thermal performance compared to QFP (Quad Flat Package) rework, which deals with gull-wing leads extending from the package sides. BGA rework requires specialized infrared or hot air reflow tools due to hidden solder joints under the package, whereas QFP rework can use traditional soldering irons more easily because leads are externally accessible. The critical difference lies in inspection and heat control: BGA demands precise temperature profiling and X-ray inspection for joint verification, while QFP inspection is more straightforward with optical methods.

Tools and Equipment Required for BGA Rework

BGA rework demands specialized tools such as precision infrared rework stations, hotspot thermal profiling systems, and soldering flux dispensers designed to handle the delicate ball grid array components. Unlike QFP rework, which primarily uses soldering irons and hot air guns, BGA equipment requires highly accurate temperature control and alignment fixtures to prevent damage to the PCB and ensure reliable solder joints. Essential accessories include vacuum nozzles for component placement, clips for PCB stabilization, and inspection microscopes to detect micro-solder defects during the rework process.

Tools and Equipment Required for QFP Rework

QFP rework requires specialized tools such as hot air rework stations, precision soldering irons, and fine-tipped soldering tools designed for handling small leads and pads. Stencil printers and solder paste applicators improve solder accuracy during QFP reflow processes. Effective QFP rework also often involves magnification devices and PCB holders to ensure precision alignment and prevent damage to adjacent components.

BGA Rework Process Overview

BGA rework involves precise removal and replacement of ball grid array components using specialized infrared or hot air reflow stations to ensure reliable solder joint formation. The process includes careful alignment, controlled heating profiles to avoid PCB damage, and inspection with X-ray imaging for hidden solder connections. Compared to QFP rework, BGA rework demands advanced equipment and higher technical skill due to the component's arrayed solder balls beneath the package.

QFP Rework Process Overview

The QFP rework process involves carefully removing the Quad Flat Package from the PCB using controlled heat to avoid damaging surrounding components. Precise solder removal, pad cleaning, and alignment are crucial steps before placing the new QFP for reflow soldering. This procedure requires specialized tools such as hot air rework stations and solder wick to ensure reliable electrical connections and maintain board integrity.

Common Challenges in BGA Rework

BGA rework commonly faces challenges such as precise temperature control to avoid solder joint damage and the risk of hidden solder voids beneath the array, which can cause intermittent connections. Ensuring proper alignment is critical, given the ball grid's dense and compact layout, making visual inspection difficult compared to QFP rework. Additionally, the requirement for specialized rework equipment to uniformly heat the component complicates the repair process, increasing the potential for thermal stress and component damage.

Common Challenges in QFP Rework

QFP rework often encounters challenges such as fine-pitch lead alignment issues, increasing the risk of solder bridging and thermal damage. Unlike BGA rework, QFP requires meticulous handling of exposed leads, which complicates solder joint inspection and repair. Precise temperature control is critical to prevent lifting or warping of fragile QFP leads during the reflow process.

Cost and Time Considerations: BGA vs QFP Rework

BGA rework typically incurs higher costs and longer repair times due to the complexity of properly heating and aligning solder balls underneath the component. QFP rework is generally faster and less expensive, as the leads are exposed and easier to access for soldering or replacement. Efficient BGA rework requires specialized equipment such as infrared reflow stations, whereas QFP rework can often be completed with standard soldering tools, making it cost-effective for smaller-scale repairs.

Choosing Between BGA and QFP Rework for Your Project

Choosing between BGA and QFP rework depends on the complexity and density of the PCB design. BGA rework suits high-density applications requiring precise ball alignment and heat management, while QFP rework is more straightforward with visible leads enabling easier inspection and soldering. Project requirements such as component size, thermal sensitivity, and rework equipment availability also influence the decision.

BGA Rework vs QFP Rework Infographic

productdif.com

productdif.com