DC motors provide smooth and continuous rotation ideal for applications requiring variable speed and torque control, while stepper motors excel in precise positioning and repeatability due to their discrete step movements. The choice between DC and stepper motors depends on the need for either continuous rotation with speed variability or exact angular positioning without feedback. Stepper motors are commonly used in CNC machines and 3D printers, whereas DC motors are preferred in robotics and conveyor systems.

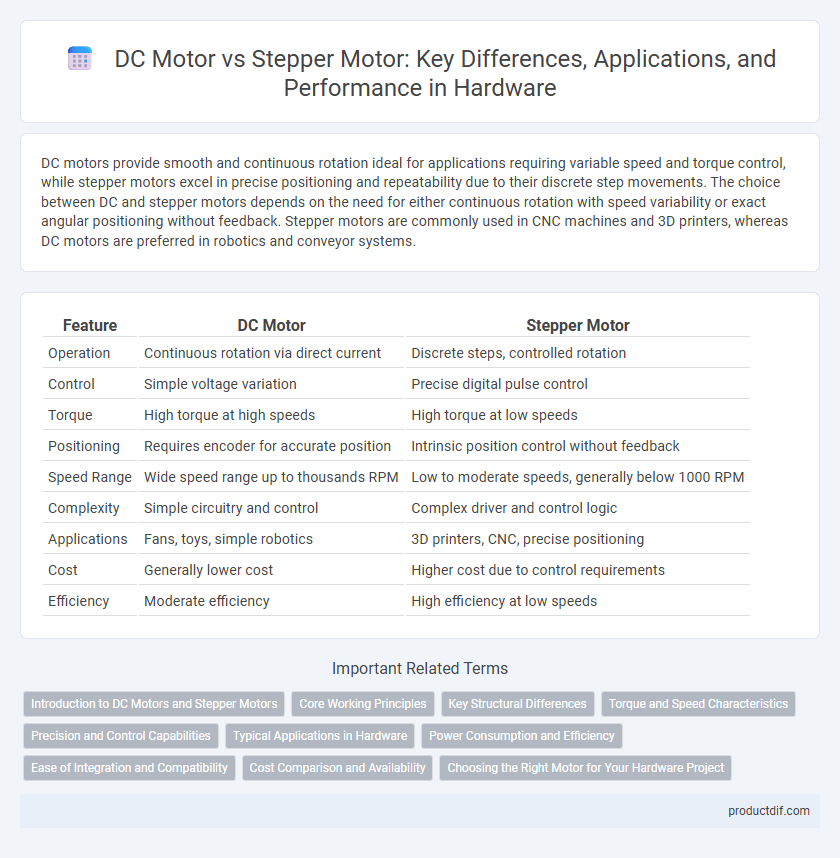

Table of Comparison

| Feature | DC Motor | Stepper Motor |

|---|---|---|

| Operation | Continuous rotation via direct current | Discrete steps, controlled rotation |

| Control | Simple voltage variation | Precise digital pulse control |

| Torque | High torque at high speeds | High torque at low speeds |

| Positioning | Requires encoder for accurate position | Intrinsic position control without feedback |

| Speed Range | Wide speed range up to thousands RPM | Low to moderate speeds, generally below 1000 RPM |

| Complexity | Simple circuitry and control | Complex driver and control logic |

| Applications | Fans, toys, simple robotics | 3D printers, CNC, precise positioning |

| Cost | Generally lower cost | Higher cost due to control requirements |

| Efficiency | Moderate efficiency | High efficiency at low speeds |

Introduction to DC Motors and Stepper Motors

DC motors convert direct current electrical energy into mechanical rotation using a commutator and brushes, offering smooth and continuous motion ideal for applications requiring variable speed and high torque. Stepper motors operate by dividing a full rotation into equal steps, providing precise position control without feedback sensors, making them suitable for applications like 3D printers and CNC machines. Both motor types are essential in hardware systems, with DC motors favored for continuous rotation tasks and stepper motors preferred for accurate positioning.

Core Working Principles

DC motors operate on the principle of electromagnetic induction, where a current-carrying conductor placed in a magnetic field experiences a force causing rotational motion. Stepper motors function by dividing a full rotation into discrete steps using multiple electromagnets energized in sequence to achieve precise position control. The key difference lies in continuous rotation induced by commutator action in DC motors versus incremental angular movement driven by controlled energizing of stator coils in stepper motors.

Key Structural Differences

DC motors have a simple construction consisting of a rotor, stator, brushes, and a commutator, enabling continuous rotation and smooth speed control. Stepper motors feature a more complex design with multiple electromagnetic coils organized in phases that allow precise control of angular position through incremental step movements. The absence of brushes in stepper motors reduces maintenance and enhances reliability compared to the brushed design of DC motors.

Torque and Speed Characteristics

DC motors provide continuous rotation with high speed capability and relatively lower torque at startup, making them ideal for applications requiring smooth motion and variable speed control. Stepper motors offer precise position control with high torque at low speeds due to their discrete step movements, but their maximum speed is limited compared to DC motors. Torque in stepper motors remains stable at low speeds, while DC motors excel in maintaining torque over a broader speed range.

Precision and Control Capabilities

DC motors offer smooth rotational motion with variable speed control but lack inherent precision in positioning, making them less suitable for applications requiring exact angle control. Stepper motors provide exceptional precision by moving in discrete steps, enabling accurate positioning without feedback systems, which is ideal for CNC machines and 3D printers. Control capabilities in stepper motors include open-loop control for simple tasks and closed-loop systems for enhanced accuracy, whereas DC motors often rely on encoders for precise feedback and control.

Typical Applications in Hardware

DC motors are commonly used in applications requiring continuous rotation and variable speed control, such as robotics, conveyor belts, and electric vehicles. Stepper motors excel in precision positioning tasks found in 3D printers, CNC machines, and camera platforms, where exact movements are crucial. The choice depends on whether the application prioritizes smooth rotation or accurate, repeatable positioning.

Power Consumption and Efficiency

DC motors typically offer higher efficiency and lower power consumption under continuous load due to their ability to maintain speed with less energy. Stepper motors consume more power as they draw current constantly to hold position, resulting in lower overall efficiency, especially at higher torque levels. For applications requiring precise positioning with moderate power, stepper motors are less energy-efficient compared to variable-speed DC motors.

Ease of Integration and Compatibility

DC motors offer simpler integration with basic controllers and are widely compatible with various power supplies and control systems, making them ideal for straightforward applications. Stepper motors require more complex drivers and precise control signals, which can complicate integration but provide greater positioning accuracy. Compatibility of stepper motors with microcontrollers and modern digital interfaces enhances their use in applications demanding precise motion control.

Cost Comparison and Availability

DC motors typically offer a lower initial cost and widespread availability due to their simpler design and common use in various applications. Stepper motors, while generally more expensive upfront, provide precise position control and are readily available but at a higher price point, especially in specialized models. The overall cost-effectiveness depends on the specific application requirements, with DC motors favored for budget-sensitive projects and stepper motors preferred where precision justifies the expense.

Choosing the Right Motor for Your Hardware Project

Selecting the right motor for your hardware project depends on the required precision and control; DC motors provide continuous rotation with variable speed, ideal for applications needing smooth motion and high torque. Stepper motors offer precise position control by dividing a full rotation into discrete steps, making them suitable for tasks requiring accurate positioning such as 3D printers and CNC machines. Evaluating factors like torque, speed control, power consumption, and complexity of the control system ensures optimal performance and efficiency in your project.

DC motor vs Stepper motor Infographic

productdif.com

productdif.com