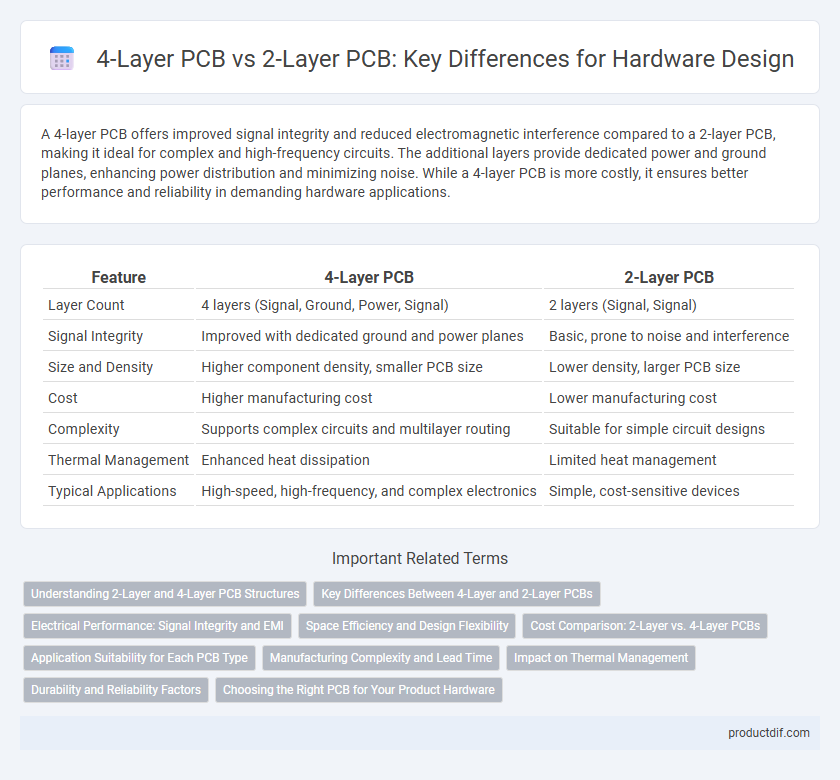

A 4-layer PCB offers improved signal integrity and reduced electromagnetic interference compared to a 2-layer PCB, making it ideal for complex and high-frequency circuits. The additional layers provide dedicated power and ground planes, enhancing power distribution and minimizing noise. While a 4-layer PCB is more costly, it ensures better performance and reliability in demanding hardware applications.

Table of Comparison

| Feature | 4-Layer PCB | 2-Layer PCB |

|---|---|---|

| Layer Count | 4 layers (Signal, Ground, Power, Signal) | 2 layers (Signal, Signal) |

| Signal Integrity | Improved with dedicated ground and power planes | Basic, prone to noise and interference |

| Size and Density | Higher component density, smaller PCB size | Lower density, larger PCB size |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Complexity | Supports complex circuits and multilayer routing | Suitable for simple circuit designs |

| Thermal Management | Enhanced heat dissipation | Limited heat management |

| Typical Applications | High-speed, high-frequency, and complex electronics | Simple, cost-sensitive devices |

Understanding 2-Layer and 4-Layer PCB Structures

A 2-layer PCB consists of two copper layers--one on the top and one on the bottom--allowing for basic circuit designs with simple routing and limited component density. A 4-layer PCB includes two internal layers in addition to the top and bottom layers, enabling enhanced signal integrity, reduced electromagnetic interference, and more complex circuit layouts. The extra layers in a 4-layer PCB facilitate dedicated power and ground planes, improving overall electrical performance and thermal management compared to a 2-layer PCB.

Key Differences Between 4-Layer and 2-Layer PCBs

A 4-layer PCB features four distinct conductive layers, typically including two signal layers, one power plane, and one ground plane, providing superior electromagnetic interference (EMI) shielding and signal integrity compared to a 2-layer PCB that has only two signal layers. The increased layer count in 4-layer PCBs allows for more complex and compact circuit designs, improved thermal management, and enhanced routing options, whereas 2-layer PCBs are simpler, cost-effective solutions suitable for less demanding applications. Manufacturing costs and design complexity rise with 4-layer PCBs, making 2-layer PCBs ideal for low-cost, high-volume production with fewer routing constraints.

Electrical Performance: Signal Integrity and EMI

Four-layer PCBs significantly enhance electrical performance by providing dedicated ground and power planes, which improve signal integrity and reduce electromagnetic interference (EMI) through better shielding and controlled impedance. The additional layers minimize crosstalk and signal loss, crucial for high-speed or high-frequency applications, compared to two-layer PCBs that rely on fewer routing options and lack internal planes. This layered structure enables more stable voltage distribution and reduces loop area, ultimately optimizing overall electromagnetic compatibility (EMC) and system reliability.

Space Efficiency and Design Flexibility

A 4-layer PCB offers superior space efficiency by accommodating more complex circuits within a smaller footprint compared to a 2-layer PCB, making it ideal for compact hardware designs. Enhanced design flexibility in 4-layer PCBs comes from additional routing layers and dedicated ground and power planes, which improve signal integrity and reduce electromagnetic interference. While 2-layer PCBs are simpler and cost-effective for less complex applications, 4-layer PCBs enable more sophisticated hardware architecture and optimized component placement.

Cost Comparison: 2-Layer vs. 4-Layer PCBs

2-layer PCBs generally offer a lower cost due to simpler manufacturing processes and fewer materials compared to 4-layer PCBs. The additional layers in 4-layer PCBs increase fabrication complexity, resulting in higher expenses for lamination, drilling, and inspection. While 4-layer designs provide enhanced signal integrity and reduced electromagnetic interference, the cost difference can be significant for budget-sensitive projects.

Application Suitability for Each PCB Type

4-layer PCBs are ideal for complex electronic devices requiring enhanced signal integrity, power distribution, and electromagnetic interference (EMI) control, commonly used in advanced computing, telecommunications, and automotive electronics. 2-layer PCBs suit simpler, low-cost applications such as consumer electronics, basic industrial controls, and LED lighting where signal complexity and noise are minimal. Selecting between 4-layer and 2-layer PCBs depends on design complexity, frequency requirements, and environmental constraints, with 4-layer offering superior performance for high-speed, high-density circuits.

Manufacturing Complexity and Lead Time

A 4-layer PCB involves more intricate manufacturing processes due to additional lamination and precise alignment of inner layers, resulting in increased complexity compared to a 2-layer PCB. The extended fabrication steps for 4-layer boards typically lead to longer lead times, often doubling the production duration relative to 2-layer PCBs. Manufacturers must balance multilevel circuit density and thermal management against the increased time and complexity when choosing between 4-layer and 2-layer PCBs.

Impact on Thermal Management

A 4-layer PCB offers superior thermal management compared to a 2-layer PCB due to its internal power and ground planes that efficiently dissipate heat. The additional layers provide enhanced heat spreading capabilities, reducing hotspot formation and improving overall reliability in high-power applications. Effective thermal management in 4-layer PCBs minimizes thermal stress on components, extending device lifespan and performance stability.

Durability and Reliability Factors

Four-layer PCBs offer enhanced durability and reliability compared to two-layer PCBs due to their additional internal layers that provide better signal integrity, reduced electromagnetic interference, and improved thermal dissipation. The increased number of layers allows for more efficient power distribution and ground planes, which minimizes noise and voltage fluctuations, ensuring consistent device performance. Enhanced mechanical strength from the extra layers also improves resistance to physical stress and environmental factors, extending the overall lifespan of the hardware.

Choosing the Right PCB for Your Product Hardware

Choosing the right PCB for your product hardware depends on factors such as signal integrity, electrical noise reduction, and space constraints. A 4-layer PCB offers enhanced performance with dedicated power and ground planes, improving electromagnetic compatibility and thermal management compared to a 2-layer PCB. For complex circuits requiring higher density and reliability, a 4-layer PCB is preferable, while simpler, cost-sensitive designs may benefit from the lower cost and ease of manufacturing of a 2-layer PCB.

4-layer PCB vs 2-layer PCB Infographic

productdif.com

productdif.com