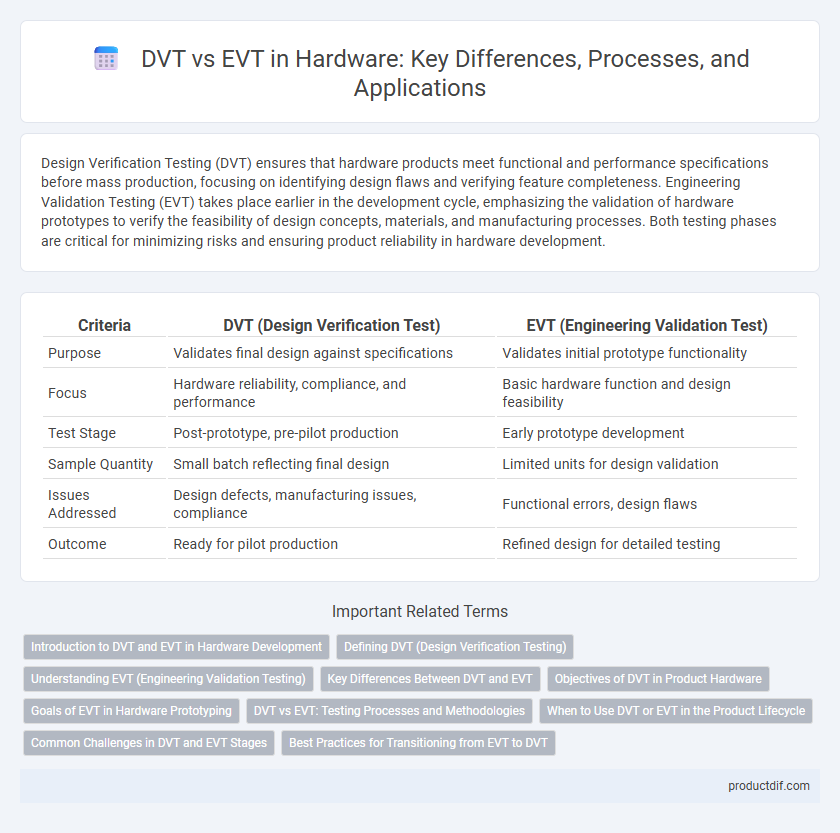

Design Verification Testing (DVT) ensures that hardware products meet functional and performance specifications before mass production, focusing on identifying design flaws and verifying feature completeness. Engineering Validation Testing (EVT) takes place earlier in the development cycle, emphasizing the validation of hardware prototypes to verify the feasibility of design concepts, materials, and manufacturing processes. Both testing phases are critical for minimizing risks and ensuring product reliability in hardware development.

Table of Comparison

| Criteria | DVT (Design Verification Test) | EVT (Engineering Validation Test) |

|---|---|---|

| Purpose | Validates final design against specifications | Validates initial prototype functionality |

| Focus | Hardware reliability, compliance, and performance | Basic hardware function and design feasibility |

| Test Stage | Post-prototype, pre-pilot production | Early prototype development |

| Sample Quantity | Small batch reflecting final design | Limited units for design validation |

| Issues Addressed | Design defects, manufacturing issues, compliance | Functional errors, design flaws |

| Outcome | Ready for pilot production | Refined design for detailed testing |

Introduction to DVT and EVT in Hardware Development

DVT (Design Validation Testing) and EVT (Engineering Validation Testing) are critical phases in hardware development focused on ensuring product functionality and design accuracy. EVT evaluates prototype designs to identify engineering issues and confirm compliance with specifications, while DVT rigorously tests near-final hardware to validate performance, reliability, and manufacturability. Both tests play essential roles in minimizing defects and optimizing hardware quality before mass production.

Defining DVT (Design Verification Testing)

Design Verification Testing (DVT) is a critical phase in hardware development focused on validating the complete system against design specifications to ensure functionality, performance, and reliability. DVT involves exhaustive testing of hardware components and firmware integration to identify defects before mass production. This process optimizes product quality and minimizes costly post-production failures by verifying compliance with required standards and customer requirements.

Understanding EVT (Engineering Validation Testing)

Engineering Validation Testing (EVT) is a critical phase in hardware development focused on validating the design and functionality of prototypes before mass production. EVT tests ensure that the hardware components meet the specified engineering requirements and performance standards by identifying design flaws and assembly issues early. Successful completion of EVT reduces risks and lays the foundation for subsequent stages like Design Validation Testing (DVT) and Production Validation Testing (PVT).

Key Differences Between DVT and EVT

Design Validation Testing (DVT) focuses on verifying the complete design's functionality and performance under real-world conditions to ensure the product meets specifications. Engineering Validation Testing (EVT) occurs earlier in the development cycle, concentrating on validating individual components and subsystems to identify and fix engineering issues. DVT emphasizes final product validation, while EVT targets early design feasibility and hardware reliability.

Objectives of DVT in Product Hardware

Design Verification Testing (DVT) aims to validate the hardware's functionality, reliability, and compliance with design specifications before mass production. This phase focuses on identifying design flaws, ensuring component interoperability, and confirming performance under real-world operating conditions. DVT helps reduce costly post-production fixes and enhances product quality by rigorously testing the integrated hardware system.

Goals of EVT in Hardware Prototyping

EVT (Engineering Validation Test) in hardware prototyping primarily targets verifying design functionality, ensuring that the hardware operates according to specifications under real-world conditions. Unlike DVT (Design Validation Test), which focuses more on finalizing the design for mass production, EVT aims to identify and resolve critical design flaws early in the development cycle. Key goals include validating electrical performance, mechanical fit, and thermal characteristics to confirm the prototype meets foundational engineering requirements before progressing to DVT.

DVT vs EVT: Testing Processes and Methodologies

Design Verification Testing (DVT) focuses on validating the complete hardware design against specifications through exhaustive functional tests, including system-level stress and performance analysis. Engineering Validation Testing (EVT) emphasizes early prototype assessments, targeting hardware functionality and identifying critical design flaws through basic operational tests and preliminary power measurements. DVT involves more comprehensive and rigorous testing environments compared to EVT's initial validation phase, ensuring hardware readiness for subsequent production and certification stages.

When to Use DVT or EVT in the Product Lifecycle

Design Verification Testing (DVT) is essential during the later stages of the product lifecycle to validate the complete hardware system's functionality, performance, and reliability against design specifications. Engineering Validation Testing (EVT) occurs earlier in the cycle, focusing on verifying the core design and identifying potential design issues during initial prototype development. Use EVT to detect fundamental design flaws and hardware feasibility, shifting to DVT for comprehensive system validation before mass production.

Common Challenges in DVT and EVT Stages

Common challenges in Design Verification Test (DVT) and Engineering Verification Test (EVT) stages include identifying functional discrepancies and hardware-software integration issues that affect overall product performance. Both stages require rigorous testing of electrical signals, thermal conditions, and physical durability to ensure reliability under diverse operational environments. Debugging complex failures during DVT and EVT often demands extensive cross-functional collaboration to resolve design flaws before moving to subsequent validation phases.

Best Practices for Transitioning from EVT to DVT

During the transition from Engineering Validation Test (EVT) to Design Validation Test (DVT), it is essential to implement rigorous documentation and maintain clear communication across cross-functional hardware teams to ensure design changes are accurately captured and validated. Establish thorough test plans that incorporate lessons learned from EVT to optimize test coverage and identify potential reliability issues early. Leveraging automated testing tools and continuous feedback loops accelerates defect detection, enabling smoother progression towards production readiness in hardware development.

DVT vs EVT Infographic

productdif.com

productdif.com