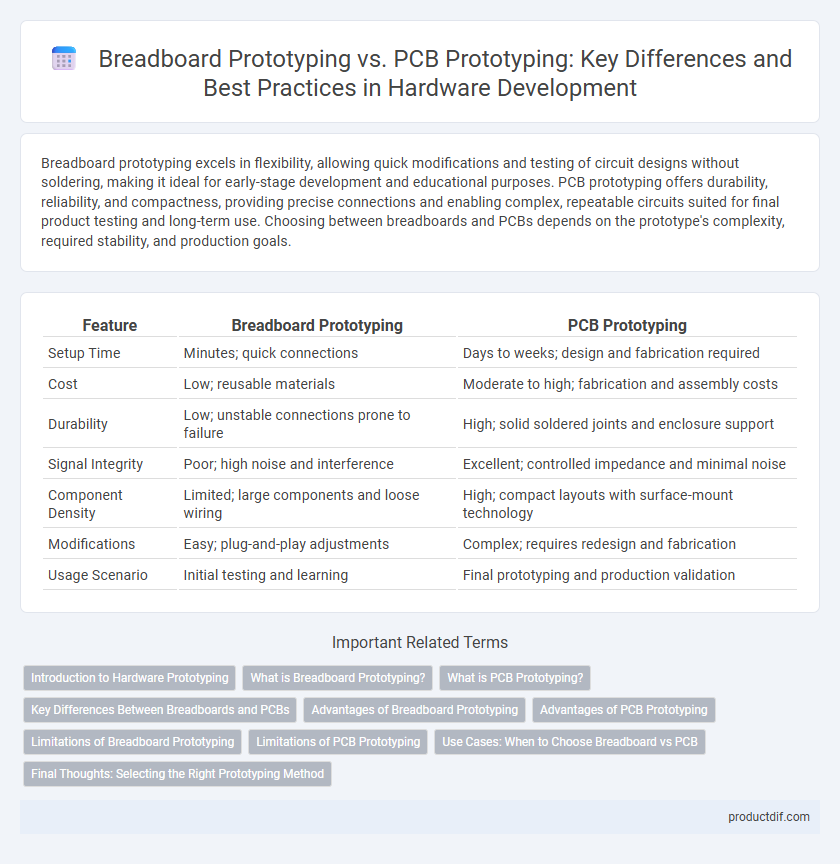

Breadboard prototyping excels in flexibility, allowing quick modifications and testing of circuit designs without soldering, making it ideal for early-stage development and educational purposes. PCB prototyping offers durability, reliability, and compactness, providing precise connections and enabling complex, repeatable circuits suited for final product testing and long-term use. Choosing between breadboards and PCBs depends on the prototype's complexity, required stability, and production goals.

Table of Comparison

| Feature | Breadboard Prototyping | PCB Prototyping |

|---|---|---|

| Setup Time | Minutes; quick connections | Days to weeks; design and fabrication required |

| Cost | Low; reusable materials | Moderate to high; fabrication and assembly costs |

| Durability | Low; unstable connections prone to failure | High; solid soldered joints and enclosure support |

| Signal Integrity | Poor; high noise and interference | Excellent; controlled impedance and minimal noise |

| Component Density | Limited; large components and loose wiring | High; compact layouts with surface-mount technology |

| Modifications | Easy; plug-and-play adjustments | Complex; requires redesign and fabrication |

| Usage Scenario | Initial testing and learning | Final prototyping and production validation |

Introduction to Hardware Prototyping

Hardware prototyping involves creating a preliminary model to test and validate electronic circuits before full-scale production. Breadboard prototyping offers a flexible and reusable platform for quick circuit assembly without soldering, ideal for early-stage experimentation and rapid iteration. PCB prototyping provides a durable, precise layout with professional-grade connections, essential for testing finalized designs under real-world conditions.

What is Breadboard Prototyping?

Breadboard prototyping involves assembling electronic components on a reusable, solderless platform that features a grid of interconnected holes for easy circuit design and testing. It enables rapid experimentation and modification without permanent connections, making it ideal for initial development and troubleshooting. This method supports the use of standard through-hole components and jumper wires, facilitating quick adjustments before committing to a printed circuit board (PCB) design.

What is PCB Prototyping?

PCB prototyping is the process of designing and manufacturing a printed circuit board to test and validate electronic circuits before mass production. It involves creating a physical board with etched copper pathways that connect electronic components according to a specific schematic. This method ensures durability, precise connections, and professional-quality layouts for complex and high-performance hardware applications.

Key Differences Between Breadboards and PCBs

Breadboards offer a flexible, solderless platform ideal for quick circuit testing and iterative design, while PCBs provide a permanent, reliable solution with precise component placement and robust electrical connections. Breadboards support easy modifications but suffer from loose contacts and signal interference, whereas PCBs ensure durability, better performance at high frequencies, and compact layouts. Designers choose breadboards for early-stage prototyping and PCBs for finalized, production-ready electronics.

Advantages of Breadboard Prototyping

Breadboard prototyping offers rapid circuit assembly without soldering, enabling easy modifications and troubleshooting during the design phase. Its reusable nature reduces material costs and accelerates iterative testing compared to PCB prototyping. Breadboards also support immediate component swaps, facilitating experimental flexibility in hardware development.

Advantages of PCB Prototyping

PCB prototyping offers superior electrical performance and durability compared to breadboard prototyping, ensuring stable and reliable circuit connections with reduced signal interference. It enables precise component placement and soldering, which enhances mechanical strength and supports higher frequency operation critical for advanced hardware designs. PCB prototypes also facilitate easier replication and scalability, significantly accelerating the transition from prototype to production in hardware development.

Limitations of Breadboard Prototyping

Breadboard prototyping faces limitations such as unreliable connections due to loose contacts and susceptibility to signal noise, which affect circuit performance and accuracy. It is unsuitable for high-frequency or high-current applications because of limited current-carrying capacity and parasitic capacitance issues. The lack of permanence and mechanical stability often leads to accidental disconnections and difficulty in troubleshooting complex circuits.

Limitations of PCB Prototyping

PCB prototyping involves high initial costs due to custom fabrication and longer turnaround times compared to breadboard prototyping, limiting rapid iteration. Design errors in PCB prototyping can lead to costly re-manufacturing processes, increasing project expenses and delays. Complex modifications are difficult to implement on PCBs, reducing flexibility during the development phase compared to the easily adjustable breadboard setups.

Use Cases: When to Choose Breadboard vs PCB

Breadboard prototyping suits early-stage development and quick circuit testing due to its flexibility and reusability without soldering. PCB prototyping is ideal for finalized designs requiring durability, signal integrity, and compact layouts in production-ready hardware. Choose breadboards for experimentation and iterative design, while PCBs are better for performance-critical and long-term applications.

Final Thoughts: Selecting the Right Prototyping Method

Breadboard prototyping offers flexibility and speed for early design iterations, ideal for testing circuits without permanent connections. PCB prototyping provides durability, precision, and suitability for complex or high-frequency designs, ensuring reliability in final products. Choosing the right method depends on project requirements, budget constraints, and the desired level of accuracy and reproducibility.

Breadboard Prototyping vs PCB Prototyping Infographic

productdif.com

productdif.com