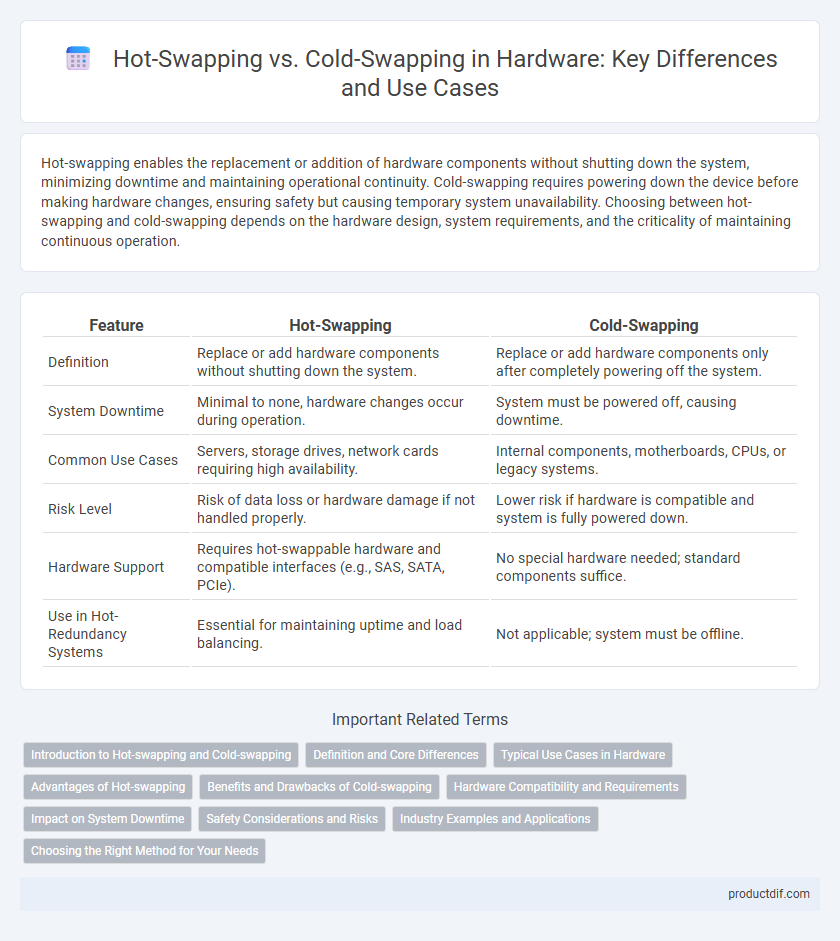

Hot-swapping enables the replacement or addition of hardware components without shutting down the system, minimizing downtime and maintaining operational continuity. Cold-swapping requires powering down the device before making hardware changes, ensuring safety but causing temporary system unavailability. Choosing between hot-swapping and cold-swapping depends on the hardware design, system requirements, and the criticality of maintaining continuous operation.

Table of Comparison

| Feature | Hot-Swapping | Cold-Swapping |

|---|---|---|

| Definition | Replace or add hardware components without shutting down the system. | Replace or add hardware components only after completely powering off the system. |

| System Downtime | Minimal to none, hardware changes occur during operation. | System must be powered off, causing downtime. |

| Common Use Cases | Servers, storage drives, network cards requiring high availability. | Internal components, motherboards, CPUs, or legacy systems. |

| Risk Level | Risk of data loss or hardware damage if not handled properly. | Lower risk if hardware is compatible and system is fully powered down. |

| Hardware Support | Requires hot-swappable hardware and compatible interfaces (e.g., SAS, SATA, PCIe). | No special hardware needed; standard components suffice. |

| Use in Hot-Redundancy Systems | Essential for maintaining uptime and load balancing. | Not applicable; system must be offline. |

Introduction to Hot-swapping and Cold-swapping

Hot-swapping enables the replacement or addition of hardware components, such as hard drives or network cards, without powering down the system, minimizing downtime and maintaining continuous operation. Cold-swapping requires shutting down the system before removing or installing hardware, reducing the risk of data corruption but increasing downtime. Understanding these methods is crucial for optimizing system availability and maintenance efficiency in data centers and enterprise environments.

Definition and Core Differences

Hot-swapping refers to the process of replacing or adding components to a computer system without shutting down the power, allowing uninterrupted operation, commonly used in servers and storage devices. Cold-swapping requires powering down the system before component replacement, minimizing the risk of hardware damage but causing downtime. The core difference lies in operational impact and safety, with hot-swapping enhancing availability and cold-swapping emphasizing hardware protection.

Typical Use Cases in Hardware

Hot-swapping is commonly used in servers, storage devices, and network equipment to replace or add components without shutting down the system, ensuring continuous operation and minimizing downtime. Cold-swapping is typically applied in desktop PCs, internal hard drives, or power supplies where full system power-off is required to avoid hardware damage or data corruption. Data centers and enterprise environments rely heavily on hot-swappable components for maintenance and scalability, while consumer electronics often utilize cold-swapping for basic hardware upgrades or repairs.

Advantages of Hot-swapping

Hot-swapping offers significant advantages in hardware maintenance by allowing components to be replaced or added without shutting down the entire system, minimizing downtime and ensuring continuous operation. This capability is essential in critical environments such as data centers and servers where uptime and reliability are paramount. Hot-swappable hardware supports easier upgrades and repairs, reducing maintenance costs and improving overall system availability.

Benefits and Drawbacks of Cold-swapping

Cold-swapping involves powering down a device before removing or installing hardware components, minimizing the risk of electrical damage and data corruption. This method ensures hardware safety and system stability, particularly for older or sensitive equipment lacking hot-swap capability. However, cold-swapping leads to increased downtime and workflow interruption, impacting productivity in environments requiring constant system availability.

Hardware Compatibility and Requirements

Hot-swapping hardware supports real-time replacement without shutting down the system, requiring components with built-in compatibility and robust connectors designed for live insertion and removal. Cold-swapping demands powering down hardware before replacement, ensuring compatibility mainly with devices lacking hot-swapping features and minimizing risk of data corruption or hardware damage. Proper hardware compatibility for hot-swapping involves advanced firmware and OS support, whereas cold-swapping compatibility relies on standard hardware interfaces and connectors.

Impact on System Downtime

Hot-swapping significantly reduces system downtime by allowing hardware components to be replaced or added without shutting down the entire system, ensuring continuous operation in critical environments. Cold-swapping requires powering down the system, leading to complete halts in service and potential productivity losses during maintenance. Data centers, servers, and enterprise-level hardware benefit most from hot-swapping due to its minimal disruption to system availability.

Safety Considerations and Risks

Hot-swapping allows hardware components like hard drives or power supplies to be replaced without shutting down the system, minimizing downtime but requiring devices designed for safe hot insertion and removal to prevent electrical damage or data loss. Cold-swapping entails powering down the system before replacement, reducing the risk of electrical shock or hardware damage but increasing system downtime. Ensuring proper grounding, following manufacturer guidelines, and verifying hardware compatibility are critical safety considerations to mitigate risks in both swapping methods.

Industry Examples and Applications

Hot-swapping is widely used in data centers with servers like Dell PowerEdge and HPE ProLiant, enabling replacement of hard drives and power supplies without shutting down systems, ensuring continuous operation and minimal downtime. Cold-swapping is common in consumer electronics and automotive industries, where devices such as desktop PCs or car components are powered off before hardware changes to prevent damage or data loss. Industries relying on high availability, such as telecommunications and cloud services, prioritize hot-swappable components for seamless maintenance, while manufacturing and testing environments often use cold-swapping due to safety and compatibility requirements.

Choosing the Right Method for Your Needs

Hot-swapping allows hardware components to be replaced or added without shutting down the system, minimizing downtime and preserving data integrity, making it ideal for high-availability environments. Cold-swapping requires powering down the device before hardware changes, ensuring safety and preventing electrical damage but causing operational interruptions. Selecting the right method depends on system compatibility, critical uptime requirements, and risk tolerance for potential hardware faults.

Hot-swapping vs Cold-swapping Infographic

productdif.com

productdif.com