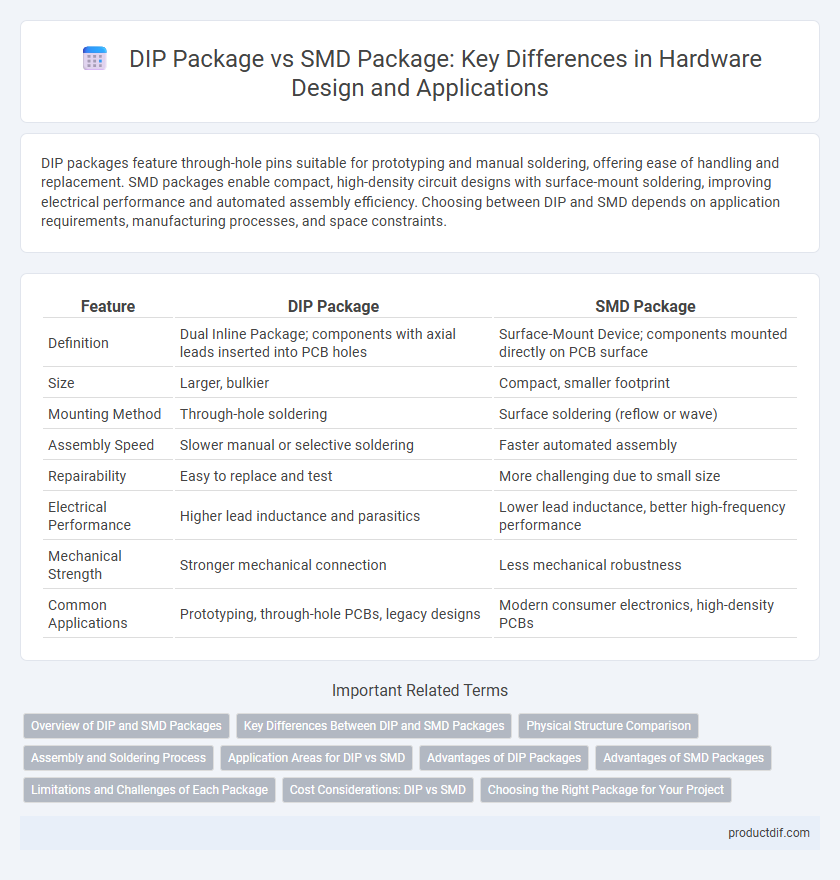

DIP packages feature through-hole pins suitable for prototyping and manual soldering, offering ease of handling and replacement. SMD packages enable compact, high-density circuit designs with surface-mount soldering, improving electrical performance and automated assembly efficiency. Choosing between DIP and SMD depends on application requirements, manufacturing processes, and space constraints.

Table of Comparison

| Feature | DIP Package | SMD Package |

|---|---|---|

| Definition | Dual Inline Package; components with axial leads inserted into PCB holes | Surface-Mount Device; components mounted directly on PCB surface |

| Size | Larger, bulkier | Compact, smaller footprint |

| Mounting Method | Through-hole soldering | Surface soldering (reflow or wave) |

| Assembly Speed | Slower manual or selective soldering | Faster automated assembly |

| Repairability | Easy to replace and test | More challenging due to small size |

| Electrical Performance | Higher lead inductance and parasitics | Lower lead inductance, better high-frequency performance |

| Mechanical Strength | Stronger mechanical connection | Less mechanical robustness |

| Common Applications | Prototyping, through-hole PCBs, legacy designs | Modern consumer electronics, high-density PCBs |

Overview of DIP and SMD Packages

DIP (Dual In-line Package) components feature two parallel rows of pins designed for through-hole mounting, providing easy manual soldering and prototyping advantages. SMD (Surface-Mount Device) packages, including variants like SOIC and QFN, enable compact layouts with pins or pads mounted directly on the PCB surface, enhancing automated assembly and high-density designs. The choice between DIP and SMD packages impacts circuit size, manufacturing methods, and electrical performance in modern electronics.

Key Differences Between DIP and SMD Packages

DIP (Dual In-line Package) components feature through-hole leads designed for manual insertion and soldering on printed circuit boards (PCBs), providing easier prototyping and repair. SMD (Surface-Mount Device) packages have smaller, flat leads or terminations soldered directly onto PCB surfaces, enabling higher component density and improved electrical performance. The primary differences lie in assembly methods, size constraints, and suitability for automated manufacturing processes, with SMD favored for miniaturization and mass production, while DIP suits low-volume or experimental setups.

Physical Structure Comparison

DIP (Dual In-line Package) features a rectangular housing with two parallel rows of through-hole pins, making it suitable for breadboarding and manual soldering. SMD (Surface Mount Device) packages are more compact, with pins or pads located on the bottom or sides for direct mounting on PCB surfaces, enabling higher circuit density. The physical structure of SMDs reduces lead length, minimizing parasitic inductance and capacitance compared to DIP packages.

Assembly and Soldering Process

DIP packages feature through-hole leads that require manual or wave soldering onto PCB holes, facilitating easy inspection and replacement but increasing assembly time. SMD packages have flat contacts soldered directly onto PCB pads using reflow soldering, enabling high-speed automated assembly and improved miniaturization. The soldering process for SMDs demands precise temperature control and solder paste application to prevent defects like tombstoning or solder bridges.

Application Areas for DIP vs SMD

DIP (Dual In-line Package) components are widely used in prototyping, through-hole mounting on PCBs, and applications requiring easy manual soldering or replacement, such as hobbyist projects and educational kits. SMD (Surface-Mount Device) packages dominate modern high-density applications, including smartphones, laptops, and compact industrial electronics, due to their smaller footprint and compatibility with automated assembly. Industries prioritizing miniaturization and high-speed production favor SMD, whereas DIP is preferred in situations demanding robustness and ease of handling.

Advantages of DIP Packages

DIP (Dual In-line Package) packages offer superior ease of handling and soldering compared to SMD (Surface-Mount Device) packages, making them ideal for prototyping and manual assembly. Their through-hole design provides stronger mechanical connections and better durability in high-stress environments, enhancing reliability in aerospace and industrial hardware. DIP packages also facilitate straightforward fault detection and replacement, reducing maintenance time and costs in complex circuit boards.

Advantages of SMD Packages

SMD packages offer higher component density, enabling more compact and efficient circuit board designs compared to DIP packages. They provide better electrical performance with shorter lead lengths that reduce parasitic inductance and capacitance. Automated pick-and-place assembly processes for SMD packages enhance manufacturing speed and consistency, lowering production costs.

Limitations and Challenges of Each Package

DIP packages face limitations in high-density circuit designs due to their larger size and through-hole mounting requirements, which complicate automated assembly processes. SMD packages present challenges in thermal management and mechanical reliability, especially in high-power applications, due to their compact form factor and surface mounting method. Both package types require careful consideration of manufacturing capabilities and application constraints to optimize performance and reliability.

Cost Considerations: DIP vs SMD

DIP packages generally incur higher manufacturing and assembly costs due to their larger size and manual placement requirements, whereas SMD packages benefit from automated surface-mount technology, reducing labor expenses and increasing production efficiency. The bulkier DIP format also leads to increased material use and PCB space, raising overall costs compared to the compact and lightweight SMD design. SMD components enable high-density PCB layouts that lower material costs and improve performance, making them more cost-effective for large-scale manufacturing.

Choosing the Right Package for Your Project

Selecting the appropriate package type between DIP (Dual In-line Package) and SMD (Surface-Mount Device) depends on factors like board space, assembly method, and application requirements. DIP packages offer ease of manual soldering and prototyping, suitable for through-hole PCB designs, while SMD packages enable higher component density and better electrical performance in automated assembly processes. Evaluating thermal management, mechanical stability, and production volume helps in choosing the optimal package to ensure reliability and cost-effectiveness in your hardware project.

DIP package vs SMD package Infographic

productdif.com

productdif.com