Benchtop testing allows precise control over environmental conditions and immediate access to diagnostic tools, making it ideal for initial hardware validation and troubleshooting in a controlled setting. Field testing exposes hardware to real-world operational conditions, revealing performance issues and durability concerns that cannot be replicated in the lab. Combining both methods ensures comprehensive evaluation, balancing controlled analysis with practical reliability assessments.

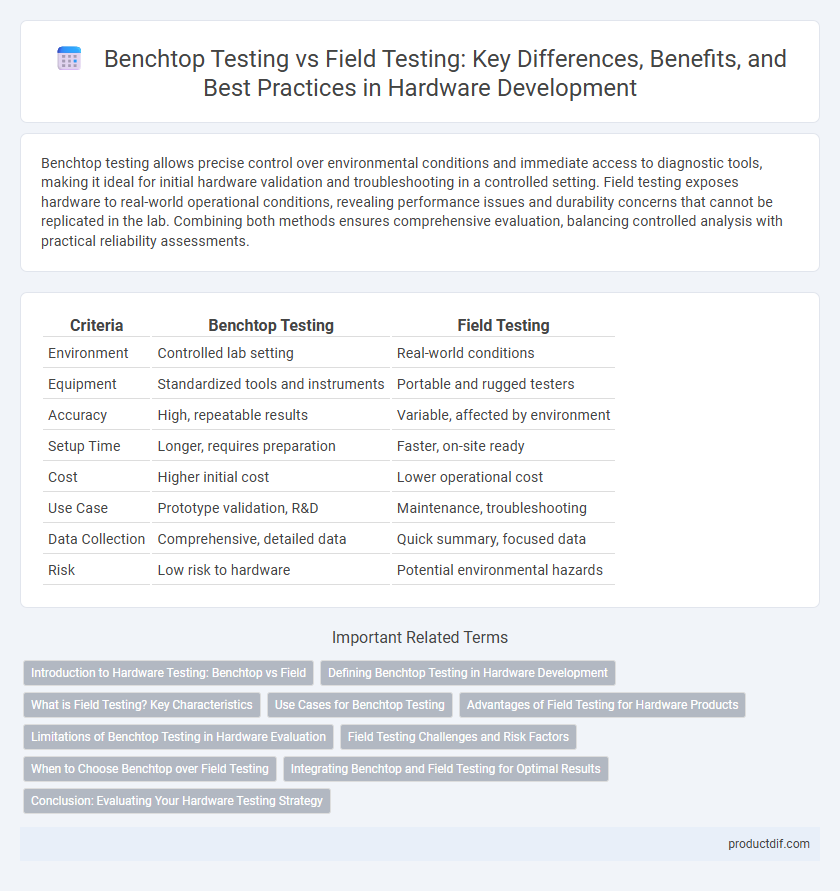

Table of Comparison

| Criteria | Benchtop Testing | Field Testing |

|---|---|---|

| Environment | Controlled lab setting | Real-world conditions |

| Equipment | Standardized tools and instruments | Portable and rugged testers |

| Accuracy | High, repeatable results | Variable, affected by environment |

| Setup Time | Longer, requires preparation | Faster, on-site ready |

| Cost | Higher initial cost | Lower operational cost |

| Use Case | Prototype validation, R&D | Maintenance, troubleshooting |

| Data Collection | Comprehensive, detailed data | Quick summary, focused data |

| Risk | Low risk to hardware | Potential environmental hazards |

Introduction to Hardware Testing: Benchtop vs Field

Benchtop testing involves evaluating hardware components in a controlled laboratory environment, allowing for precise measurement of performance and functionality without external variables. Field testing assesses hardware under real-world conditions, exposing devices to environmental factors like temperature, humidity, and physical stress to verify durability and reliability. Both methods complement each other by ensuring hardware meets design specifications and operational requirements before full deployment.

Defining Benchtop Testing in Hardware Development

Benchtop testing in hardware development involves evaluating components and subsystems within a controlled laboratory environment to ensure functionality and performance before integration. This method allows engineers to identify design flaws, verify electrical characteristics, and conduct precise measurements without external environmental variables. Benchtop testing accelerates debugging and refinement by providing repeatable and isolated conditions essential for early-stage hardware validation.

What is Field Testing? Key Characteristics

Field testing involves evaluating hardware performance in real-world environments outside the controlled conditions of a laboratory or benchtop. Key characteristics include testing under actual operating conditions, exposure to environmental variables such as temperature, humidity, and electromagnetic interference, and assessing durability, reliability, and functionality as end users would experience. This approach provides crucial data on hardware behavior, facilitating improvements that ensure product readiness for practical deployment.

Use Cases for Benchtop Testing

Benchtop testing is ideal for controlled environments where precise calibration, troubleshooting, and iterative development of hardware components are required. It allows engineers to simulate operating conditions, perform detailed measurements, and validate design parameters before deployment. This testing is essential for quality assurance in manufacturing processes and early-stage product development.

Advantages of Field Testing for Hardware Products

Field testing of hardware products provides real-world conditions that reveal performance issues and environmental impacts not detectable in controlled benchtop testing. It allows for comprehensive assessment of hardware reliability, durability, and user experience in actual operating environments, leading to more accurate validation of product functionality. Access to diverse field data facilitates identification of design improvements and accelerates iterative development cycles.

Limitations of Benchtop Testing in Hardware Evaluation

Benchtop testing in hardware evaluation is limited by its controlled environment, which often fails to replicate real-world operating conditions such as temperature fluctuations, vibration, and electromagnetic interference. This testing method restricts the assessment of hardware performance under actual usage scenarios, leading to potential discrepancies in durability and reliability predictions. Furthermore, benchtop setups may not adequately simulate user interactions or system integration challenges that hardware encounters in the field.

Field Testing Challenges and Risk Factors

Field testing in hardware development presents significant challenges such as variable environmental conditions, unpredictable user behavior, and limited control over external factors, which can lead to inconsistent data and delayed issue identification. Risk factors include potential damage to equipment due to harsh field environments, safety hazards for operators, and logistical difficulties in deploying testing personnel and resources in remote or hazardous locations. Effective mitigation requires robust test planning, real-time monitoring solutions, and comprehensive risk management strategies to ensure reliable performance validation under actual operating conditions.

When to Choose Benchtop over Field Testing

Benchtop testing is ideal when controlled environments are necessary to isolate variables and obtain precise, repeatable measurements on hardware components. Choosing benchtop testing over field testing is crucial during early design validation, troubleshooting, and calibration phases where external environmental factors could skew results. This method ensures accuracy and consistency, especially for complex electronic devices that require detailed performance analysis before deployment.

Integrating Benchtop and Field Testing for Optimal Results

Integrating benchtop testing and field testing maximizes hardware validation by combining controlled laboratory precision with real-world environmental conditions, ensuring comprehensive performance assessment and reliability. Utilizing benchtop setups to troubleshoot and refine prototypes accelerates development cycles, while field testing captures variability and user behavior challenging simulated environments. Synchronizing results from both testing phases enhances predictive maintenance strategies and optimizes hardware design for durability and functionality under operational stresses.

Conclusion: Evaluating Your Hardware Testing Strategy

Evaluating your hardware testing strategy requires balancing precision and practicality by integrating benchtop testing's controlled environment with field testing's real-world conditions. Benchtop testing offers detailed diagnostics and repeatability crucial for initial validation, while field testing reveals hardware performance under actual operating stresses, identifying issues not apparent in the lab. Combining these methods enhances reliability, accelerates troubleshooting, and ensures robust hardware validation across development stages.

Benchtop Testing vs Field Testing Infographic

productdif.com

productdif.com