Ball Grid Array (BGA) packages offer higher pin density and better thermal and electrical performance compared to Quad Flat Package (QFP) components, making BGAs ideal for compact and high-speed hardware applications. QFPs provide easier visual inspection and rework due to their exposed leads, benefiting prototyping and repair scenarios in hardware design. Selecting between BGA and QFP depends on factors such as device complexity, space constraints, manufacturing capabilities, and long-term reliability requirements.

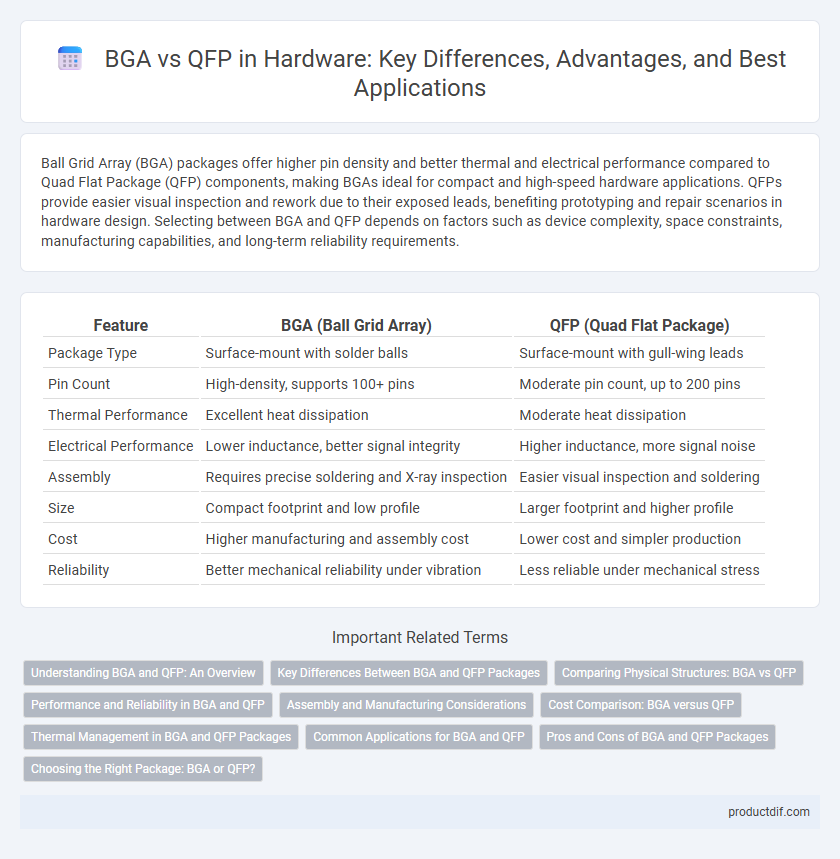

Table of Comparison

| Feature | BGA (Ball Grid Array) | QFP (Quad Flat Package) |

|---|---|---|

| Package Type | Surface-mount with solder balls | Surface-mount with gull-wing leads |

| Pin Count | High-density, supports 100+ pins | Moderate pin count, up to 200 pins |

| Thermal Performance | Excellent heat dissipation | Moderate heat dissipation |

| Electrical Performance | Lower inductance, better signal integrity | Higher inductance, more signal noise |

| Assembly | Requires precise soldering and X-ray inspection | Easier visual inspection and soldering |

| Size | Compact footprint and low profile | Larger footprint and higher profile |

| Cost | Higher manufacturing and assembly cost | Lower cost and simpler production |

| Reliability | Better mechanical reliability under vibration | Less reliable under mechanical stress |

Understanding BGA and QFP: An Overview

Ball Grid Array (BGA) packages offer superior electrical performance and thermal dissipation compared to Quad Flat Packages (QFP) due to their array of solder balls underneath the chip, enabling higher pin density and better signal integrity. QFPs feature leads extending from all four sides of the package, which simplifies inspection and rework but limits pin count and may increase inductance in high-frequency applications. Understanding the structural differences and application-specific benefits of BGA and QFP is crucial for selecting the appropriate package in advanced electronic hardware designs.

Key Differences Between BGA and QFP Packages

BGA (Ball Grid Array) packages feature solder balls on the underside for electrical connections, providing improved heat dissipation and higher pin density compared to QFP (Quad Flat Package), which uses gull-wing leads extending from the sides. BGA packages offer better electrical performance and mechanical reliability due to shorter interconnects, while QFP packages are generally easier to inspect and repair. The choice between BGA and QFP depends on factors like assembly complexity, thermal management requirements, and available PCB space.

Comparing Physical Structures: BGA vs QFP

Ball Grid Array (BGA) packages feature a grid of solder balls on the underside, enabling higher pin density and improved thermal performance compared to Quad Flat Package (QFP), which uses gull-wing leads extending from all four sides. BGA's compact, bottom-terminated design reduces lead inductance and enhances electrical performance, while QFP's exposed leads allow easier visual inspection and manual soldering. The robust mechanical connection in BGA often results in better durability under thermal cycling and mechanical stress relative to the fragile lead frame in QFP.

Performance and Reliability in BGA and QFP

Ball Grid Array (BGA) packages offer superior performance and reliability compared to Quad Flat Package (QFP) designs due to their lower inductance and better heat dissipation, enhancing high-frequency signal integrity and thermal management. BGA's solder balls provide robust mechanical connections, reducing the risk of solder joint failure and improving overall durability under thermal cycling stress. QFP packages, with exposed leads, are more susceptible to mechanical damage and exhibit higher parasitic inductance, which can negatively impact signal performance in high-speed applications.

Assembly and Manufacturing Considerations

Ball Grid Array (BGA) packages offer superior assembly efficiency with automated soldering and better thermal performance compared to Quad Flat Package (QFP), which requires precise alignment and manual inspection due to its fine-pitch leads. BGA's solder balls allow for higher pin density and improved electrical performance, reducing the risk of solder bridging and enhancing manufacturability. QFPs may incur higher rework costs and are more susceptible to mechanical damage during handling, making BGAs preferable for advanced high-volume manufacturing processes.

Cost Comparison: BGA versus QFP

Ball Grid Array (BGA) packages typically incur higher initial costs than Quad Flat Package (QFP) due to their complex manufacturing processes and specialized equipment requirements. However, BGAs offer cost advantages at scale through improved board space utilization and enhanced thermal and electrical performance, reducing overall system expenses. QFPs remain a cost-effective choice for lower-volume production runs and simpler designs where assembly and rework costs are minimized.

Thermal Management in BGA and QFP Packages

BGA (Ball Grid Array) packages offer superior thermal management compared to QFP (Quad Flat Package) due to their direct solder ball connections that facilitate efficient heat dissipation through the PCB. The compact layout of BGA enables lower thermal resistance and better heat spreading, reducing hotspots during high-power operations. In contrast, QFP packages rely on exposed leads and top-side heat sinks, which are less effective in conducting heat away from the die quickly.

Common Applications for BGA and QFP

Ball Grid Array (BGA) packages are commonly used in high-performance applications such as microprocessors, GPUs, and memory modules, where dense pin count and efficient heat dissipation are critical. Quad Flat Package (QFP) is frequently applied in automotive electronics, consumer devices, and embedded systems, favored for its ease of inspection and soldering in medium pin count scenarios. Both BGA and QFP serve distinct roles in hardware design, with BGA optimized for complex, high-speed circuits and QFP suitable for moderate complexity integrated circuits.

Pros and Cons of BGA and QFP Packages

BGA (Ball Grid Array) packages offer superior electrical performance and heat dissipation due to their short interconnects and large contact area, making them ideal for high-density, high-frequency applications; however, they require specialized equipment for inspection and rework, increasing manufacturing complexity and cost. QFP (Quad Flat Package) provides easier visual inspection and simpler rework processes with lower manufacturing costs but suffers from limited pin count, higher inductance, and thermal dissipation challenges, which can impact high-speed or high-power device performance. Selecting between BGA and QFP depends on factors like device complexity, thermal requirements, and assembly capabilities.

Choosing the Right Package: BGA or QFP?

Choosing the right package between Ball Grid Array (BGA) and Quad Flat Package (QFP) depends on factors like board space, thermal performance, and signal integrity. BGA offers superior heat dissipation and higher pin density, ideal for high-performance applications requiring compact designs. QFP provides easier inspection and rework, making it suitable for prototypes or designs where debugging and manual soldering are prioritized.

BGA vs QFP Infographic

productdif.com

productdif.com