Bench testing involves evaluating hardware components in a controlled laboratory environment to ensure functionality and identify defects before deployment. Field testing assesses hardware performance in real-world conditions, providing insights on durability, reliability, and user interaction under actual usage scenarios. Comparing bench testing and field testing highlights the balance between controlled precision and practical applicability essential for robust hardware development.

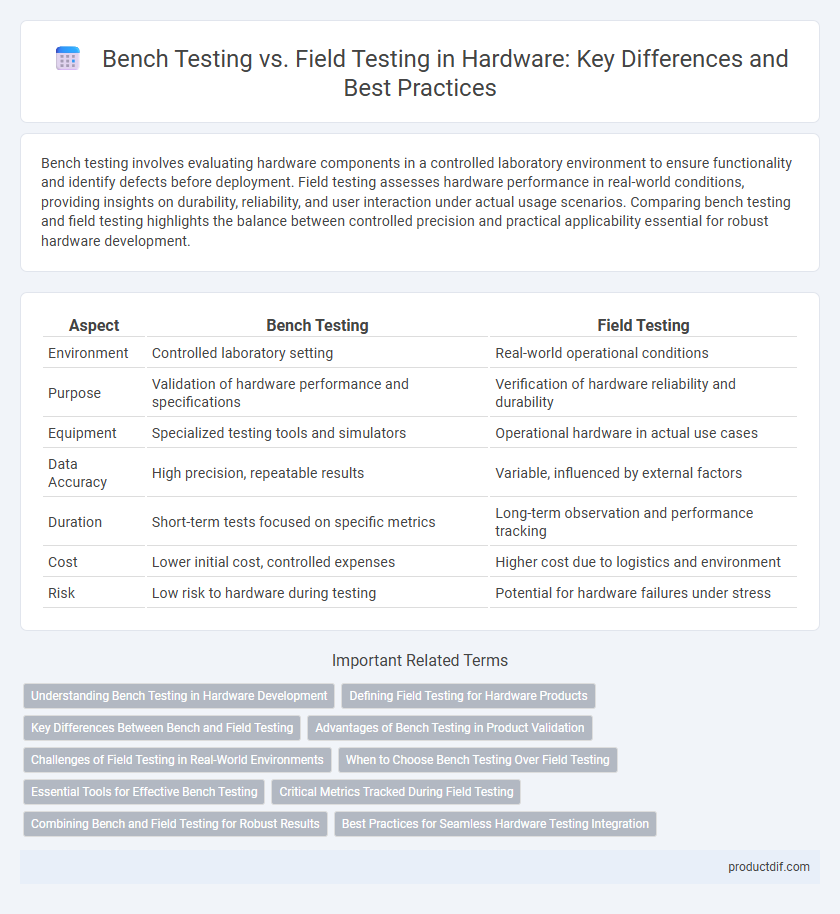

Table of Comparison

| Aspect | Bench Testing | Field Testing |

|---|---|---|

| Environment | Controlled laboratory setting | Real-world operational conditions |

| Purpose | Validation of hardware performance and specifications | Verification of hardware reliability and durability |

| Equipment | Specialized testing tools and simulators | Operational hardware in actual use cases |

| Data Accuracy | High precision, repeatable results | Variable, influenced by external factors |

| Duration | Short-term tests focused on specific metrics | Long-term observation and performance tracking |

| Cost | Lower initial cost, controlled expenses | Higher cost due to logistics and environment |

| Risk | Low risk to hardware during testing | Potential for hardware failures under stress |

Understanding Bench Testing in Hardware Development

Bench testing in hardware development involves evaluating individual components or subsystems in a controlled environment to verify functionality and performance against specifications. This process allows engineers to detect design flaws, measure electrical parameters, and validate software-hardware integration before deployment. By isolating hardware on a test bench, developers ensure reliability and reduce risks before progressing to complex field testing scenarios.

Defining Field Testing for Hardware Products

Field testing for hardware products involves evaluating the device in real-world environmental conditions to ensure performance, durability, and user interaction meet expected standards. This testing phase identifies issues related to external factors such as temperature variations, mechanical stress, and electromagnetic interference that bench testing may not reveal. Data collected from field testing helps optimize hardware design and validate long-term reliability before mass production.

Key Differences Between Bench and Field Testing

Bench testing involves evaluating hardware components in a controlled laboratory environment to ensure performance accuracy and functionality under standardized conditions. Field testing assesses hardware performance in real-world operational settings, revealing issues related to environmental factors, user interactions, and durability that are not replicable in the lab. Key differences include environmental control, with bench testing offering stable conditions, and the dynamic, unpredictable nature of field testing that provides insight into actual usage scenarios and hardware reliability over time.

Advantages of Bench Testing in Product Validation

Bench testing in product validation offers precise control over testing conditions, enabling detailed analysis of hardware components without environmental interferences. It allows early detection of design flaws through repeatable and consistent test cycles, reducing development time and costs. Controlled laboratory settings facilitate accurate measurement of performance metrics, ensuring reliable validation before field deployment.

Challenges of Field Testing in Real-World Environments

Field testing of hardware in real-world environments presents challenges such as unpredictable environmental conditions, which can affect performance and reliability. Variability in user interactions and external factors like temperature, humidity, and electromagnetic interference complicate data collection and analysis. Ensuring consistent and repeatable results in diverse, uncontrolled settings requires advanced monitoring equipment and robust testing protocols.

When to Choose Bench Testing Over Field Testing

Bench testing is preferred when controlled conditions, repeatability, and precise measurement are critical for hardware component evaluation. It allows engineers to isolate variables and identify potential design flaws before subjecting the device to unpredictable real-world environments. Selecting bench testing is ideal during early development stages to ensure functionality and compliance with specifications.

Essential Tools for Effective Bench Testing

Essential tools for effective bench testing in hardware development include oscilloscopes, multimeters, and signal generators, which allow precise measurement and analysis of electrical signals. Power supplies with adjustable voltage and current settings provide controlled environments to test components under various conditions. Data acquisition systems and specialized software enable comprehensive monitoring and recording, ensuring accurate performance evaluation before field deployment.

Critical Metrics Tracked During Field Testing

Critical metrics tracked during field testing include real-world performance indicators such as durability under various environmental conditions, power consumption rates, and thermal stability over extended usage. Unlike bench testing, which focuses on controlled conditions, field testing captures data on device reliability, signal integrity, and user interaction feedback in operational environments. Monitoring these metrics ensures hardware meets industry standards and customer expectations before full-scale deployment.

Combining Bench and Field Testing for Robust Results

Combining bench testing with field testing enhances hardware validation by leveraging controlled laboratory conditions alongside real-world operational environments, ensuring comprehensive performance assessment and reliability. Bench testing provides precise measurements and repeatability, while field testing exposes hardware to variable conditions and unexpected stresses, uncovering potential failures missed in the lab. Integrating both methods delivers robust results, accelerating product development cycles and improving long-term durability in diverse applications.

Best Practices for Seamless Hardware Testing Integration

Bench testing involves controlled environment evaluations using specialized equipment to measure hardware performance metrics precisely, while field testing assesses hardware functionality under real-world operational conditions to identify practical issues. Best practices for seamless hardware testing integration include establishing standardized test protocols, automating data collection for accurate comparison, and using iterative feedback loops to refine design and resolve discrepancies between lab and field results. Incorporating cross-functional teams ensures comprehensive analysis, accelerating product validation and enhancing reliability before market deployment.

Bench testing vs Field testing Infographic

productdif.com

productdif.com