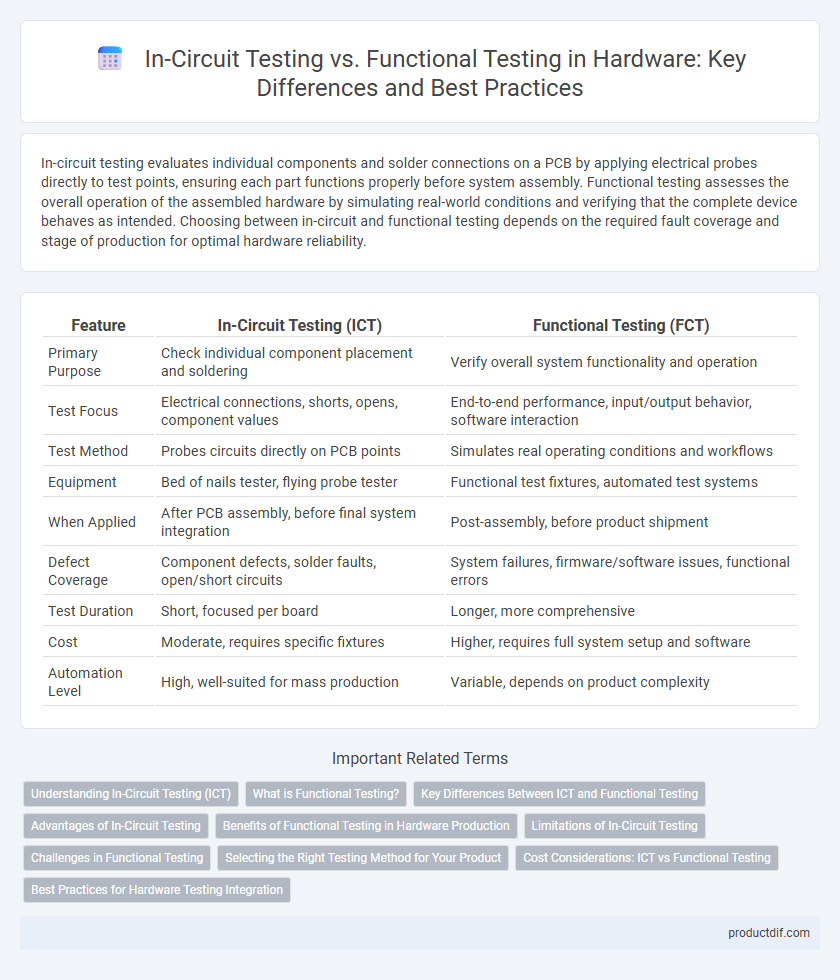

In-circuit testing evaluates individual components and solder connections on a PCB by applying electrical probes directly to test points, ensuring each part functions properly before system assembly. Functional testing assesses the overall operation of the assembled hardware by simulating real-world conditions and verifying that the complete device behaves as intended. Choosing between in-circuit and functional testing depends on the required fault coverage and stage of production for optimal hardware reliability.

Table of Comparison

| Feature | In-Circuit Testing (ICT) | Functional Testing (FCT) |

|---|---|---|

| Primary Purpose | Check individual component placement and soldering | Verify overall system functionality and operation |

| Test Focus | Electrical connections, shorts, opens, component values | End-to-end performance, input/output behavior, software interaction |

| Test Method | Probes circuits directly on PCB points | Simulates real operating conditions and workflows |

| Equipment | Bed of nails tester, flying probe tester | Functional test fixtures, automated test systems |

| When Applied | After PCB assembly, before final system integration | Post-assembly, before product shipment |

| Defect Coverage | Component defects, solder faults, open/short circuits | System failures, firmware/software issues, functional errors |

| Test Duration | Short, focused per board | Longer, more comprehensive |

| Cost | Moderate, requires specific fixtures | Higher, requires full system setup and software |

| Automation Level | High, well-suited for mass production | Variable, depends on product complexity |

Understanding In-Circuit Testing (ICT)

In-Circuit Testing (ICT) evaluates individual components on a populated printed circuit board (PCB) by measuring electrical properties such as resistance, capacitance, and shorts to verify correct assembly and soldering. ICT uses a bed-of-nails tester or flying probe tester to access test points, ensuring components like resistors, capacitors, and integrated circuits are properly placed and functional before further system-level testing. This method detects manufacturing defects early, reducing the risk of failures during Functional Testing and final product deployment.

What is Functional Testing?

Functional testing evaluates the performance and behavior of a hardware device by applying stimulus and measuring outputs to ensure it meets design specifications. This type of testing verifies the device's overall functionality in real-world operating conditions, beyond just checking individual components. Functional testing is critical for detecting system-level faults that in-circuit testing might miss, ensuring the hardware operates correctly within its intended application.

Key Differences Between ICT and Functional Testing

In-circuit testing (ICT) primarily focuses on verifying the electrical performance and integrity of individual components and solder connections on a PCB using boundary scan and fly probes. Functional testing evaluates the complete assembled board or device by simulating real-world operating conditions to confirm proper functionality and overall system behavior. While ICT excels at early fault detection and pinpointing manufacturing defects, functional testing ensures the device meets design specifications and operates correctly within its intended application.

Advantages of In-Circuit Testing

In-circuit testing (ICT) offers precise fault detection by verifying individual components and solder connections on a printed circuit board (PCB), ensuring higher test coverage compared to functional testing. ICT enables rapid diagnostics and isolation of faults at the component level, significantly reducing troubleshooting time and repair costs. This method supports automated testing processes, enhancing efficiency and consistency during mass production of electronic assemblies.

Benefits of Functional Testing in Hardware Production

Functional testing in hardware production verifies the complete operation of a device under real-world conditions, ensuring accurate performance and reliability before shipment. It detects assembly defects, component failures, and design issues that in-circuit testing might overlook, leading to higher product quality and customer satisfaction. This comprehensive validation reduces costly returns and warranty claims by confirming the device meets all functional specifications.

Limitations of In-Circuit Testing

In-circuit testing (ICT) faces limitations such as inability to detect issues related to overall device functionality or software-related faults, focusing primarily on component-level verification. It struggles with testing complex integrated circuits and modern surface-mount technologies due to limited probe access and high pin density. Functional testing complements ICT by validating the complete operational performance of hardware under realistic conditions, overcoming ICT's scope restrictions.

Challenges in Functional Testing

Functional testing faces challenges such as limited test coverage due to complex system interactions and the need for extensive test vector development to simulate real-world operating conditions. It often requires fully assembled hardware and software environments, increasing test setup time and complexity. Debugging failures in functional tests can be difficult as faults may arise from hardware, firmware, or their integration, complicating root cause analysis.

Selecting the Right Testing Method for Your Product

In-circuit testing offers precise fault detection by analyzing individual components and solder connections on a PCB, making it ideal for early-stage manufacturing quality control. Functional testing evaluates the complete hardware system under real-world operating conditions, ensuring that the product performs according to specifications. Selecting the right testing method depends on product complexity, production volume, and critical performance requirements to balance thoroughness and efficiency.

Cost Considerations: ICT vs Functional Testing

In-circuit testing (ICT) generally involves higher upfront costs due to specialized fixtures and equipment but offers cost-efficiency in detecting early component-level defects during manufacturing. Functional testing requires less initial investment but can incur greater expenses over time by identifying issues only after assembly, potentially leading to costly rework or product failures. Balancing ICT and functional testing costs depends on production volume, complexity, and defect risk, with ICT favored for high-volume runs to minimize long-term quality assurance expenses.

Best Practices for Hardware Testing Integration

In-circuit testing (ICT) provides precise fault detection by verifying individual component performance and proper soldering, making it essential for early-stage hardware validation. Functional testing ensures the complete system operates according to design specifications by simulating real-world conditions, ideal for end-of-line assessment. Integrating ICT and functional testing in hardware development optimizes defect identification, accelerates debugging, and enhances overall product quality.

In-circuit testing vs Functional testing Infographic

productdif.com

productdif.com