Custom PCBs offer tailored designs that precisely meet specific project requirements, enhancing performance and reducing unnecessary components. Off-the-shelf boards provide cost-effective and readily available solutions ideal for rapid prototyping and standard applications. Choosing between them depends on balancing customization needs, budget constraints, and development timelines.

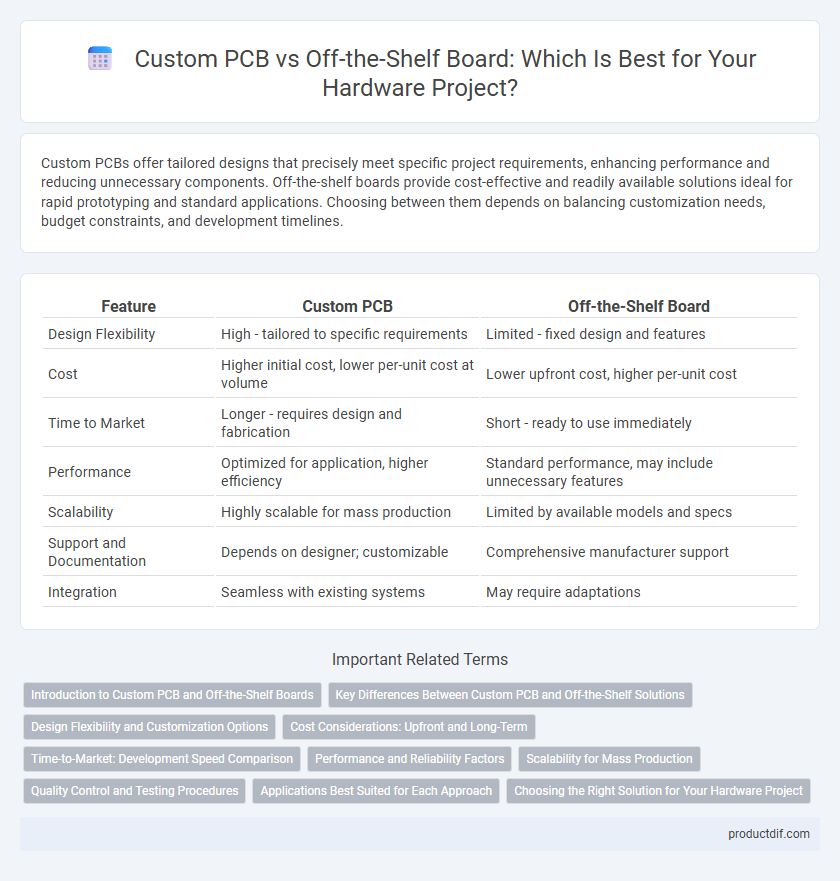

Table of Comparison

| Feature | Custom PCB | Off-the-Shelf Board |

|---|---|---|

| Design Flexibility | High - tailored to specific requirements | Limited - fixed design and features |

| Cost | Higher initial cost, lower per-unit cost at volume | Lower upfront cost, higher per-unit cost |

| Time to Market | Longer - requires design and fabrication | Short - ready to use immediately |

| Performance | Optimized for application, higher efficiency | Standard performance, may include unnecessary features |

| Scalability | Highly scalable for mass production | Limited by available models and specs |

| Support and Documentation | Depends on designer; customizable | Comprehensive manufacturer support |

| Integration | Seamless with existing systems | May require adaptations |

Introduction to Custom PCB and Off-the-Shelf Boards

Custom PCBs offer tailored circuit designs, optimized for specific hardware requirements, enabling enhanced performance, reduced size, and unique feature integration. Off-the-shelf boards provide readily available, standardized solutions suitable for general applications and rapid prototyping with broad compatibility. Selecting between custom PCB and off-the-shelf options depends on project complexity, budget constraints, and desired production volume.

Key Differences Between Custom PCB and Off-the-Shelf Solutions

Custom PCBs offer tailored circuit designs optimized for specific applications, enabling enhanced performance and space-saving layouts, whereas off-the-shelf boards provide standardized solutions with faster deployment and lower initial costs. Unlike generic boards, custom PCBs allow precise control over component placement and layer configurations, which improves signal integrity and power management. Off-the-shelf solutions often sacrifice customization for convenience, making them ideal for prototyping or low-volume production but less suitable for specialized or high-performance hardware needs.

Design Flexibility and Customization Options

Custom PCBs offer unparalleled design flexibility, enabling precise tailoring to specific project requirements, including unique form factors, layer stackups, and component placements. Off-the-shelf boards provide limited customization options, often constrained by fixed layouts and standardized components, which may not meet specialized application needs. Choosing custom PCBs enhances optimization for performance, size, and functionality, critical for advanced or niche hardware applications.

Cost Considerations: Upfront and Long-Term

Custom PCBs often involve higher upfront costs due to design, prototyping, and manufacturing setup, but they can reduce expenses in the long term by optimizing component placement and board size, leading to better performance and lower assembly costs. Off-the-shelf boards provide a cost-effective solution for immediate deployment with predictable pricing and no design fees, but they may incur higher long-term costs due to limited customization, potential inefficiencies, and the need for additional components or modifications. Evaluating total cost of ownership requires balancing initial investment against scalability, production volume, and product lifecycle demands.

Time-to-Market: Development Speed Comparison

Custom PCBs offer faster development speed for specialized applications by enabling tailored design and streamlined component placement, reducing prototyping cycles. Off-the-shelf boards provide quick deployment with pre-designed layouts but may require additional integration and adaptation time for specific use cases. Time-to-market depends on project complexity, with custom PCBs excelling in optimized functionality while off-the-shelf boards advantage simpler, rapid implementations.

Performance and Reliability Factors

Custom PCBs offer superior performance through tailored component placement and optimized trace routing, reducing signal interference and enhancing power efficiency. Off-the-shelf boards may compromise reliability due to generic design, potentially leading to thermal issues or electromagnetic compatibility problems in specific applications. Custom designs ensure higher reliability by adhering to precise specifications and rigorous testing, making them ideal for critical hardware demanding consistent performance.

Scalability for Mass Production

Custom PCBs offer superior scalability for mass production due to their tailored design, which optimizes component placement and electrical performance, reducing assembly time and costs at high volumes. Off-the-shelf boards, while readily available and cost-effective for prototyping, often lack the flexibility needed for scaling, leading to inefficiencies in large-scale manufacturing processes. Manufacturing partners typically favor custom PCBs for mass production because they can precisely match product specifications, ensuring consistency, reliability, and faster time-to-market.

Quality Control and Testing Procedures

Custom PCBs undergo rigorous quality control and testing procedures tailored to specific design requirements, ensuring higher reliability and performance consistency compared to off-the-shelf boards. Automated optical inspection (AOI), X-ray analysis, and electrical testing validate each layer and component alignment in custom PCBs, minimizing defects. Off-the-shelf boards often rely on standardized testing protocols that may overlook niche application flaws, leading to variable quality outcomes across different batches.

Applications Best Suited for Each Approach

Custom PCBs excel in specialized applications requiring unique form factors, specific electrical performance, or integration with proprietary components, making them ideal for aerospace, medical devices, and high-frequency communication systems. Off-the-shelf boards are better suited for prototyping, educational purposes, and general consumer electronics due to their standardized designs, lower cost, and faster availability. The choice depends on factors like complexity, volume, budget, and time-to-market requirements.

Choosing the Right Solution for Your Hardware Project

Selecting the right hardware solution hinges on project specifications, budget, and timeline. Custom PCBs offer tailored features, enhanced performance, and compact design ideal for complex or proprietary applications, while off-the-shelf boards provide cost-effective, readily available options suitable for prototyping and standard uses. Evaluating factors such as production volume, integration requirements, and future scalability ensures optimal alignment with project goals and overall hardware efficiency.

Custom PCB vs Off-the-Shelf Board Infographic

productdif.com

productdif.com