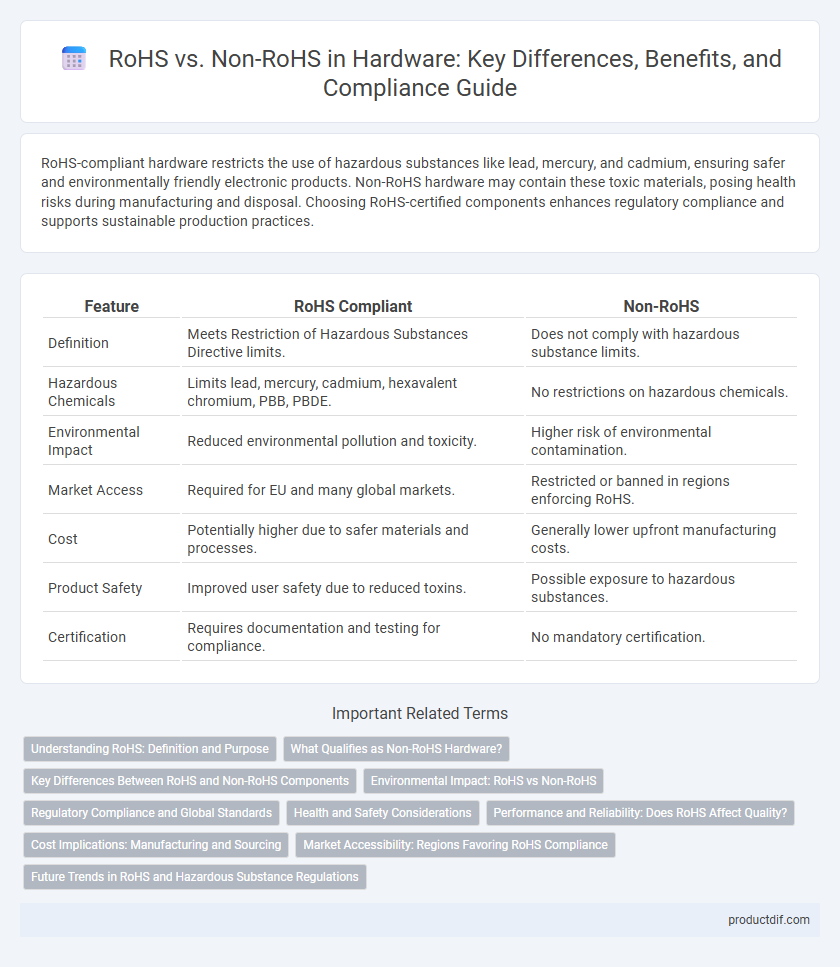

RoHS-compliant hardware restricts the use of hazardous substances like lead, mercury, and cadmium, ensuring safer and environmentally friendly electronic products. Non-RoHS hardware may contain these toxic materials, posing health risks during manufacturing and disposal. Choosing RoHS-certified components enhances regulatory compliance and supports sustainable production practices.

Table of Comparison

| Feature | RoHS Compliant | Non-RoHS |

|---|---|---|

| Definition | Meets Restriction of Hazardous Substances Directive limits. | Does not comply with hazardous substance limits. |

| Hazardous Chemicals | Limits lead, mercury, cadmium, hexavalent chromium, PBB, PBDE. | No restrictions on hazardous chemicals. |

| Environmental Impact | Reduced environmental pollution and toxicity. | Higher risk of environmental contamination. |

| Market Access | Required for EU and many global markets. | Restricted or banned in regions enforcing RoHS. |

| Cost | Potentially higher due to safer materials and processes. | Generally lower upfront manufacturing costs. |

| Product Safety | Improved user safety due to reduced toxins. | Possible exposure to hazardous substances. |

| Certification | Requires documentation and testing for compliance. | No mandatory certification. |

Understanding RoHS: Definition and Purpose

RoHS (Restriction of Hazardous Substances) is a European Union directive aimed at limiting the use of specific hazardous materials found in electrical and electronic equipment to reduce environmental and health risks. It prohibits substances such as lead, mercury, cadmium, hexavalent chromium, and certain flame retardants like PBB and PBDE, ensuring safer hardware manufacturing and disposal. Non-RoHS hardware does not comply with these restrictions, potentially containing harmful substances that pose environmental and health hazards during production, use, and recycling.

What Qualifies as Non-RoHS Hardware?

Non-RoHS hardware refers to electronic components and assemblies that do not comply with the Restriction of Hazardous Substances Directive, meaning they contain hazardous materials such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), or polybrominated diphenyl ethers (PBDE) above regulated limits. These components are often manufactured without restrictions on these substances, commonly used in legacy equipment or specialized industrial applications where compliance is not mandatory. Non-RoHS hardware poses environmental and health risks due to the toxic nature of these substances and is increasingly being phased out in favor of RoHS-compliant materials.

Key Differences Between RoHS and Non-RoHS Components

RoHS components comply with the Restriction of Hazardous Substances directive, limiting hazardous materials such as lead, mercury, cadmium, and hexavalent chromium, ensuring safer environmental impact and human health. Non-RoHS components may contain these toxic substances, posing risks in disposal and regulatory compliance, especially in regions like the EU and China with strict environmental laws. The key differences revolve around material composition, environmental safety, regulatory adherence, and often price and performance variations due to the use of safer alternative materials.

Environmental Impact: RoHS vs Non-RoHS

RoHS-compliant hardware significantly reduces hazardous substances such as lead, mercury, and cadmium, minimizing environmental pollution and facilitating safer recycling and disposal processes. Non-RoHS hardware contains higher levels of toxic materials, leading to increased soil and water contamination and posing greater risks to ecosystems and human health. Choosing RoHS-certified components supports sustainable manufacturing and aligns with global regulations aimed at reducing electronic waste impact.

Regulatory Compliance and Global Standards

RoHS-compliant hardware meets stringent regulatory standards restricting hazardous substances like lead, mercury, and cadmium, ensuring safer environmental and human health impacts. Non-RoHS products often fail to comply with international regulations such as the European Union's Directive 2011/65/EU, limiting their acceptance in global markets. Adhering to RoHS standards facilitates market access and aligns manufacturing processes with global sustainability mandates.

Health and Safety Considerations

RoHS-compliant hardware restricts the use of hazardous substances such as lead, mercury, and cadmium, significantly reducing health risks associated with exposure during manufacturing and disposal. Non-RoHS hardware may contain these toxic materials, posing potential threats to workers' health and increasing environmental hazards through improper waste handling. Prioritizing RoHS-compliant components enhances workplace safety and aligns with global efforts to minimize toxic exposure.

Performance and Reliability: Does RoHS Affect Quality?

RoHS-compliant hardware maintains performance standards comparable to non-RoHS devices, as lead-free solders and materials have been optimized for equivalent electrical connectivity and thermal properties. Reliability tests indicate that RoHS products exhibit similar long-term durability and resistance to environmental stress, minimizing failure rates in critical applications. Quality differences are negligible when manufacturers implement precise process controls, ensuring RoHS compliance does not compromise hardware effectiveness or lifespan.

Cost Implications: Manufacturing and Sourcing

RoHS-compliant hardware typically incurs higher manufacturing costs due to the use of restricted, lead-free materials and stricter quality control processes, impacting sourcing strategies. Non-RoHS components often reduce upfront expenses but risk potential regulatory fines and market limitations in regions enforcing environmental standards. Evaluating long-term cost implications requires balancing immediate savings against compliance-driven supply chain adjustments and potential product obsolescence.

Market Accessibility: Regions Favoring RoHS Compliance

Markets such as the European Union, Japan, South Korea, and Taiwan strongly favor RoHS-compliant hardware due to stringent environmental regulations and increasing consumer demand for sustainable products. Non-RoHS hardware often faces restricted market access, higher tariffs, and reduced competitiveness in these regions, impacting global distribution and sales strategies. Compliance with RoHS directives enhances market accessibility and aligns with international standards prioritizing the reduction of hazardous substances in electronic products.

Future Trends in RoHS and Hazardous Substance Regulations

Future trends in RoHS legislation indicate an expansion of restricted substances to include emerging hazardous chemicals used in hardware manufacturing. Stricter global enforcement and harmonization of RoHS directives aim to enhance environmental safety and reduce electronic waste toxicity. Manufacturers increasingly adopt non-RoHS-compliant alternatives to cut costs, but market demand and regulatory pressure drive a shift toward sustainable, RoHS-compliant hardware solutions.

RoHS vs non-RoHS Infographic

productdif.com

productdif.com