The Bill of Materials (BOM) lists all the physical components and raw materials required to manufacture a product, detailing quantities and specifications. The Bill of Process (BOP) outlines the sequence of operations, tools, and instructions necessary for the assembly and production stages. Understanding the distinction between BOM and BOP is crucial for efficient production planning and cost control in hardware manufacturing.

Table of Comparison

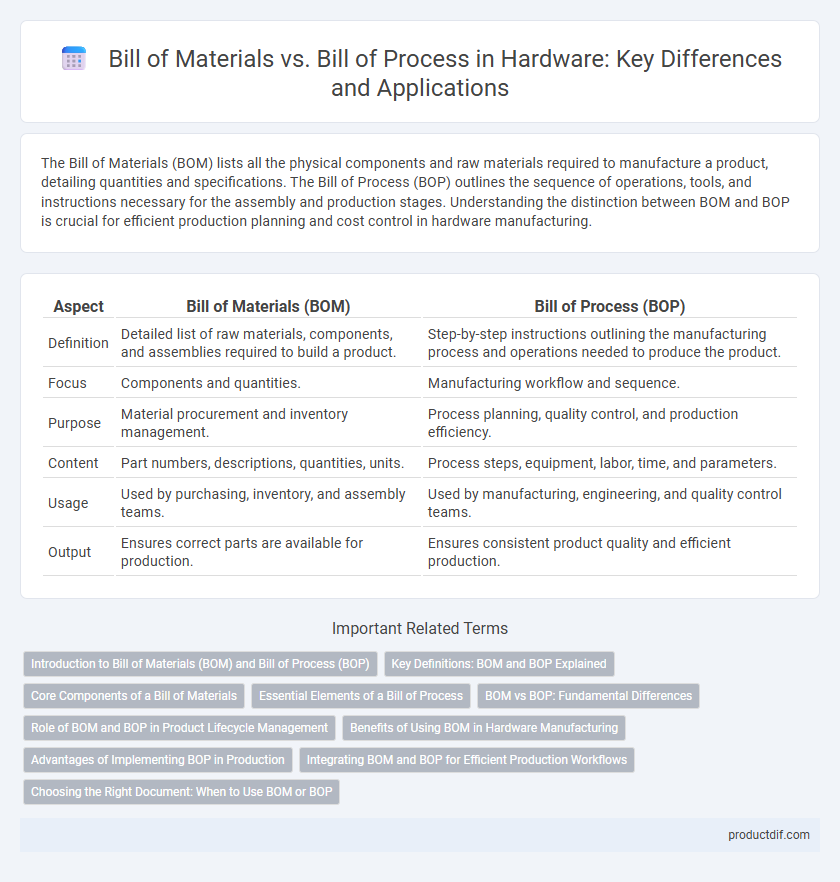

| Aspect | Bill of Materials (BOM) | Bill of Process (BOP) |

|---|---|---|

| Definition | Detailed list of raw materials, components, and assemblies required to build a product. | Step-by-step instructions outlining the manufacturing process and operations needed to produce the product. |

| Focus | Components and quantities. | Manufacturing workflow and sequence. |

| Purpose | Material procurement and inventory management. | Process planning, quality control, and production efficiency. |

| Content | Part numbers, descriptions, quantities, units. | Process steps, equipment, labor, time, and parameters. |

| Usage | Used by purchasing, inventory, and assembly teams. | Used by manufacturing, engineering, and quality control teams. |

| Output | Ensures correct parts are available for production. | Ensures consistent product quality and efficient production. |

Introduction to Bill of Materials (BOM) and Bill of Process (BOP)

The Bill of Materials (BOM) is a comprehensive list detailing all raw materials, components, and assemblies required to manufacture a hardware product, serving as a critical reference for procurement and inventory management. The Bill of Process (BOP) outlines the sequence of manufacturing steps and operations necessary to transform materials into the final product, emphasizing workflow efficiency and production planning. Together, BOM and BOP provide essential frameworks for hardware production by combining material specifications with process instructions.

Key Definitions: BOM and BOP Explained

The Bill of Materials (BOM) is a detailed list of raw materials, components, and assemblies required to manufacture a product, crucial for inventory management and procurement. The Bill of Process (BOP) outlines the specific manufacturing steps, methods, and equipment needed to transform materials into the final product, emphasizing workflow efficiency and quality control. Both BOM and BOP serve as foundational documents in hardware production, ensuring alignment between design, materials, and manufacturing processes.

Core Components of a Bill of Materials

The core components of a Bill of Materials (BOM) include detailed listings of raw materials, sub-assemblies, components, and quantities required for product manufacturing. Unlike a Bill of Process, which outlines the manufacturing steps and procedures, a BOM focuses on the accurate specification of physical parts, part numbers, descriptions, and sourcing information. Precise BOMs ensure cost control, inventory management, and seamless assembly in hardware production.

Essential Elements of a Bill of Process

A Bill of Process (BOP) details the sequence of manufacturing steps, necessary tools, and equipment required to transform raw materials into finished products, emphasizing process parameters and quality checkpoints. Essential elements include operation descriptions, machine settings, labor requirements, and inspection criteria, ensuring consistency and efficiency in production workflows. Unlike a Bill of Materials (BOM), which lists components and quantities, the BOP focuses on the procedural framework critical for process control and product integrity.

BOM vs BOP: Fundamental Differences

The Bill of Materials (BOM) lists all components, parts, and raw materials needed to manufacture a product, focusing primarily on inventory and procurement details. The Bill of Process (BOP) outlines the specific sequence of manufacturing steps, including machine operations, labor tasks, and quality checks required to assemble the product. Unlike BOM, which emphasizes the "what" in production, BOP concentrates on the "how," providing detailed instructions for efficient and standardized manufacturing workflows.

Role of BOM and BOP in Product Lifecycle Management

The Bill of Materials (BOM) provides a detailed list of raw materials, components, and assemblies required to build a hardware product, serving as a foundation for inventory management and cost estimation throughout the product lifecycle. The Bill of Process (BOP) outlines the manufacturing steps, equipment, and labor needed to transform materials into the finished product, playing a critical role in process planning, quality control, and production efficiency. Together, BOM and BOP facilitate comprehensive Product Lifecycle Management (PLM) by integrating design specifications with manufacturing workflows, ensuring seamless coordination from development to delivery.

Benefits of Using BOM in Hardware Manufacturing

The Bill of Materials (BOM) in hardware manufacturing provides a detailed list of all components, parts, and raw materials required, ensuring precise inventory management and cost estimation. Utilizing a BOM enables streamlined procurement processes and minimizes production delays by clearly defining component specifications and quantities. Enhanced traceability and quality control arise from the BOM's comprehensive documentation, facilitating easier identification of defects or sourcing issues during hardware assembly.

Advantages of Implementing BOP in Production

Implementing a Bill of Process (BOP) in hardware production enhances manufacturing efficiency by providing detailed step-by-step instructions, reducing errors compared to relying solely on a Bill of Materials (BOM). BOP integration enables improved traceability and quality control throughout the assembly stages, ensuring consistent product standards. This process-oriented documentation supports better resource allocation and workflow optimization, leading to reduced production time and lower operational costs.

Integrating BOM and BOP for Efficient Production Workflows

Integrating Bill of Materials (BOM) and Bill of Process (BOP) streamlines production workflows by aligning component specifications with manufacturing steps, reducing errors and lead times. BOM details every part and material required for product assembly, while BOP outlines the sequence and methods of fabrication and assembly. Synchronizing these documents enables real-time updates and coordination between procurement, inventory management, and production scheduling, optimizing resource utilization and ensuring product quality.

Choosing the Right Document: When to Use BOM or BOP

Choosing the right document between Bill of Materials (BOM) and Bill of Process (BOP) depends on the manufacturing stage and focus. BOM lists all the components, parts, and raw materials needed to create a product, making it essential during inventory control and procurement. BOP, detailing the step-by-step manufacturing processes and workflow, is crucial for production planning and quality control.

Bill of Materials vs Bill of Process Infographic

productdif.com

productdif.com