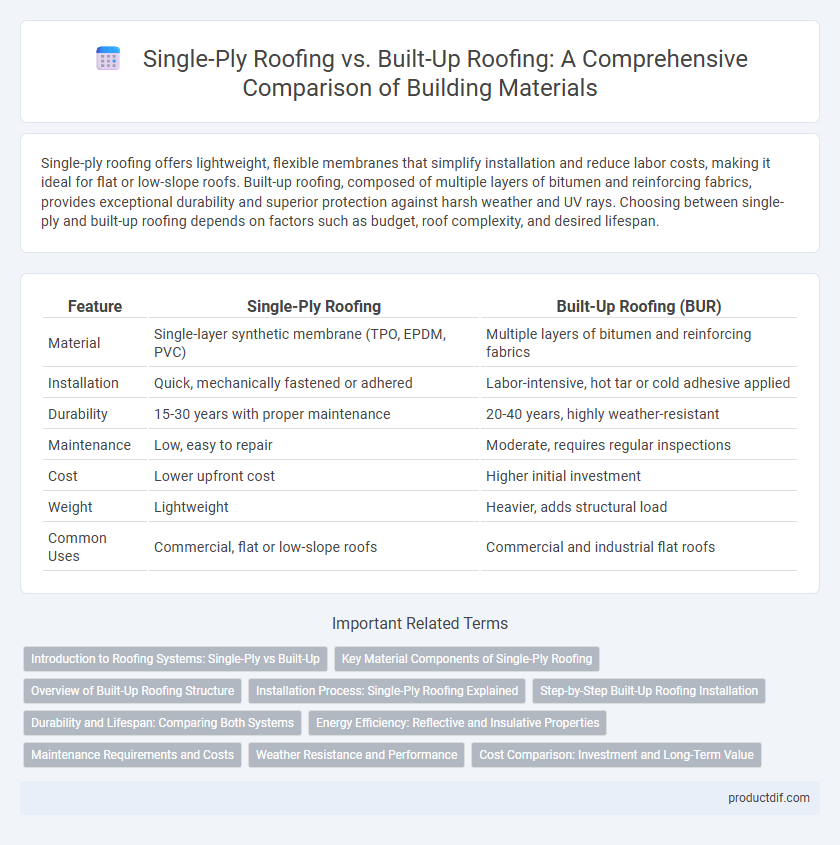

Single-ply roofing offers lightweight, flexible membranes that simplify installation and reduce labor costs, making it ideal for flat or low-slope roofs. Built-up roofing, composed of multiple layers of bitumen and reinforcing fabrics, provides exceptional durability and superior protection against harsh weather and UV rays. Choosing between single-ply and built-up roofing depends on factors such as budget, roof complexity, and desired lifespan.

Table of Comparison

| Feature | Single-Ply Roofing | Built-Up Roofing (BUR) |

|---|---|---|

| Material | Single-layer synthetic membrane (TPO, EPDM, PVC) | Multiple layers of bitumen and reinforcing fabrics |

| Installation | Quick, mechanically fastened or adhered | Labor-intensive, hot tar or cold adhesive applied |

| Durability | 15-30 years with proper maintenance | 20-40 years, highly weather-resistant |

| Maintenance | Low, easy to repair | Moderate, requires regular inspections |

| Cost | Lower upfront cost | Higher initial investment |

| Weight | Lightweight | Heavier, adds structural load |

| Common Uses | Commercial, flat or low-slope roofs | Commercial and industrial flat roofs |

Introduction to Roofing Systems: Single-Ply vs Built-Up

Single-ply roofing systems use flexible sheets of synthetic materials like TPO, EPDM, or PVC, offering durability and ease of installation for commercial buildings. Built-up roofing (BUR) involves multiple layers of bitumen alternated with reinforcing fabrics, creating a robust and watertight barrier commonly used in flat or low-slope roofs. Understanding the material composition, installation process, and performance characteristics is essential for selecting the appropriate roofing system based on building needs and environmental conditions.

Key Material Components of Single-Ply Roofing

Single-ply roofing primarily consists of synthetic membranes such as TPO (thermoplastic olefin), EPDM (ethylene propylene diene monomer), and PVC (polyvinyl chloride), which provide flexibility and durability. These membranes are typically reinforced with polyester or fiberglass mats to enhance tensile strength and resistance to punctures. Key components also include heat-welded seams or adhesive bonding systems that ensure water-tight integrity and ease of installation compared to traditional built-up roofing layers.

Overview of Built-Up Roofing Structure

Built-Up Roofing (BUR) consists of multiple layers of bitumen alternated with reinforcing fabrics, creating a durable and highly waterproof membrane. This multi-ply system typically includes asphalt or coal tar as the binding agent, topped with a reflective surfacing such as gravel or mineral granules to protect against UV radiation. BUR's layered structure provides excellent resistance to weather, mechanical damage, and fire, making it a preferred choice for flat or low-slope commercial roofs.

Installation Process: Single-Ply Roofing Explained

Single-ply roofing involves the application of large, flexible sheets of synthetic membrane, such as TPO, EPDM, or PVC, which are mechanically fastened, fully adhered, or ballasted onto the roof deck. This installation method is faster and less labor-intensive compared to built-up roofing, often requiring fewer layers and less material handling. The membrane's lightweight nature reduces structural load, making single-ply systems ideal for commercial buildings with flat or low-slope roofs.

Step-by-Step Built-Up Roofing Installation

Built-up roofing installation involves a multi-layer process starting with the application of a base sheet for waterproofing, followed by alternating layers of hot asphalt and reinforcing felts to build durability and weather resistance. Each layer must be evenly spread and properly adhered to prevent leaks and ensure structural integrity. The final step includes embedding a top layer of aggregate or a reflective coating to enhance UV resistance and prolong roof lifespan.

Durability and Lifespan: Comparing Both Systems

Single-ply roofing membranes, such as TPO and EPDM, typically offer a lifespan of 20 to 30 years with strong resistance to UV rays, chemical exposure, and weathering, making them highly durable for commercial buildings. Built-up roofing (BUR) systems, composed of multiple asphalt and ply layers, provide exceptional durability and can last 30 to 40 years when properly maintained, benefiting from excellent waterproofing and resistance to heavy foot traffic. Comparing durability and lifespan, BUR systems generally outlast single-ply membranes but require more labor-intensive installation and maintenance.

Energy Efficiency: Reflective and Insulative Properties

Single-ply roofing systems, such as TPO and PVC, offer superior energy efficiency due to their highly reflective surfaces that reduce heat absorption and lower cooling costs. Built-up roofing (BUR) utilizes multiple layers of asphalt and felt that provide excellent insulation but often lack the reflective properties essential for minimizing solar heat gain. Choosing single-ply roofing enhances energy savings by increasing roof reflectivity and decreasing urban heat island effects, while built-up roofs provide long-term durability with moderate insulating benefits.

Maintenance Requirements and Costs

Single-ply roofing systems typically require less maintenance due to their durable, flexible membranes such as TPO or EPDM, which resist cracking and UV damage, leading to lower long-term upkeep costs. Built-up roofing (BUR) involves multiple layers of bitumen and reinforcing fabrics that demand regular inspection for blisters, cracks, and water pooling, increasing maintenance frequency and expenses. Overall, single-ply roofing offers cost-effective maintenance benefits, while BUR's complexity results in higher sustained maintenance costs over time.

Weather Resistance and Performance

Single-ply roofing membranes, such as EPDM, TPO, and PVC, offer excellent weather resistance with high UV stability and flexibility, making them ideal for extreme temperature fluctuations and heavy rainfall. Built-up roofing (BUR) systems, composed of multiple layers of bitumen and reinforcing fabrics, provide superior durability and exceptional waterproofing through robust, multi-layer protection against wind uplift and ponding water. Both systems demonstrate strong performance in resisting weather-related damage, but single-ply roofs excel in ease of installation and maintenance, while BUR roofs deliver long-lasting resilience in harsh climates.

Cost Comparison: Investment and Long-Term Value

Single-ply roofing systems typically offer lower initial installation costs compared to built-up roofing due to their lightweight materials and faster installation process. Built-up roofing, while more expensive upfront, provides exceptional durability and multiple layers that enhance waterproofing and lifespan, often resulting in lower maintenance expenses over time. Evaluating total cost of ownership, built-up roofing can deliver greater long-term value for commercial buildings with heavy foot traffic or harsh environmental conditions.

Single-Ply Roofing vs Built-Up Roofing Infographic

productdif.com

productdif.com